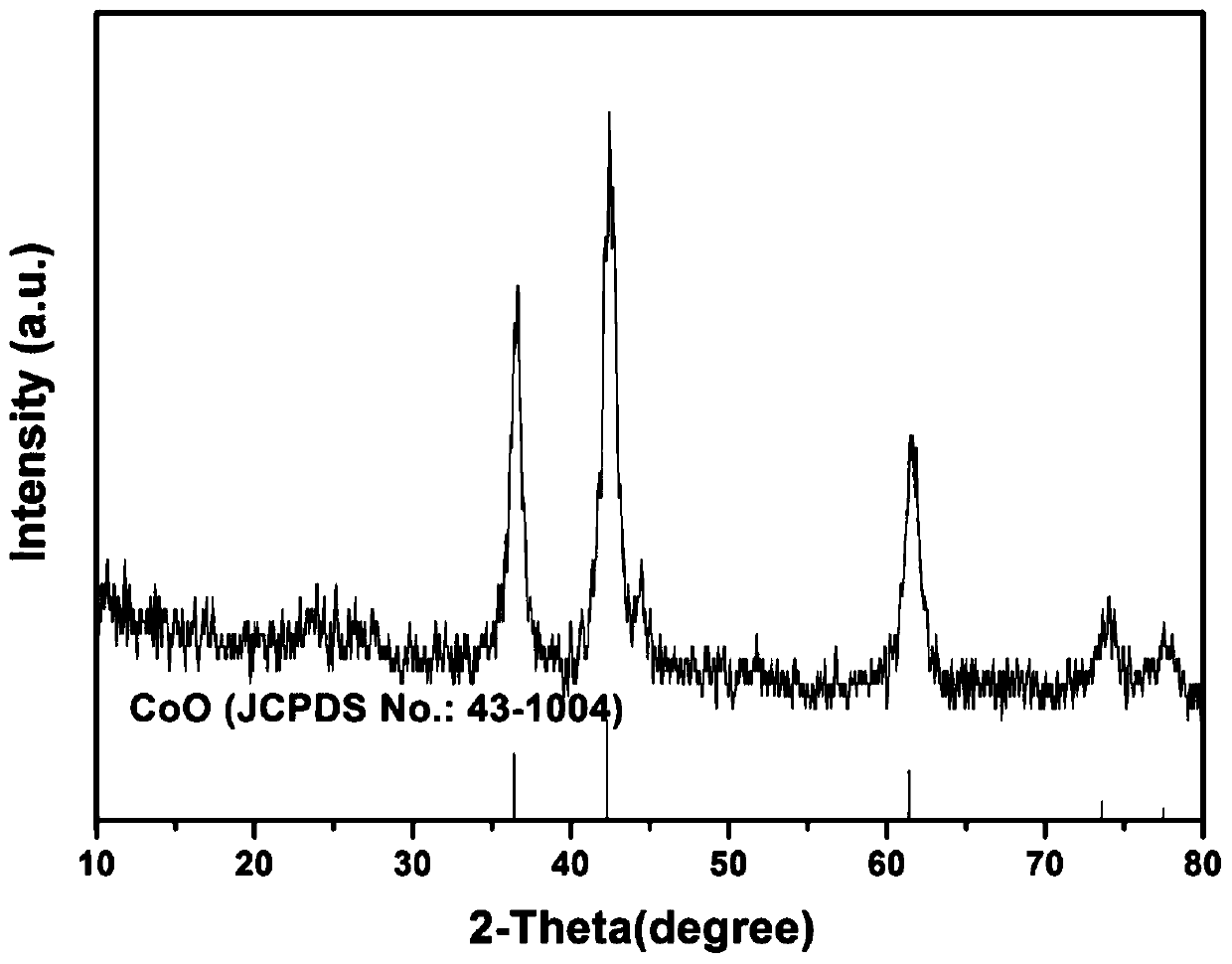

A kind of COO/reduced graphene oxide composite negative electrode material and preparation method thereof

A negative electrode material and graphene technology, which is applied in the field of CoO/reduced graphene oxide composite negative electrode material and its preparation, and achieves the effects of small size, simple and mild preparation process, and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

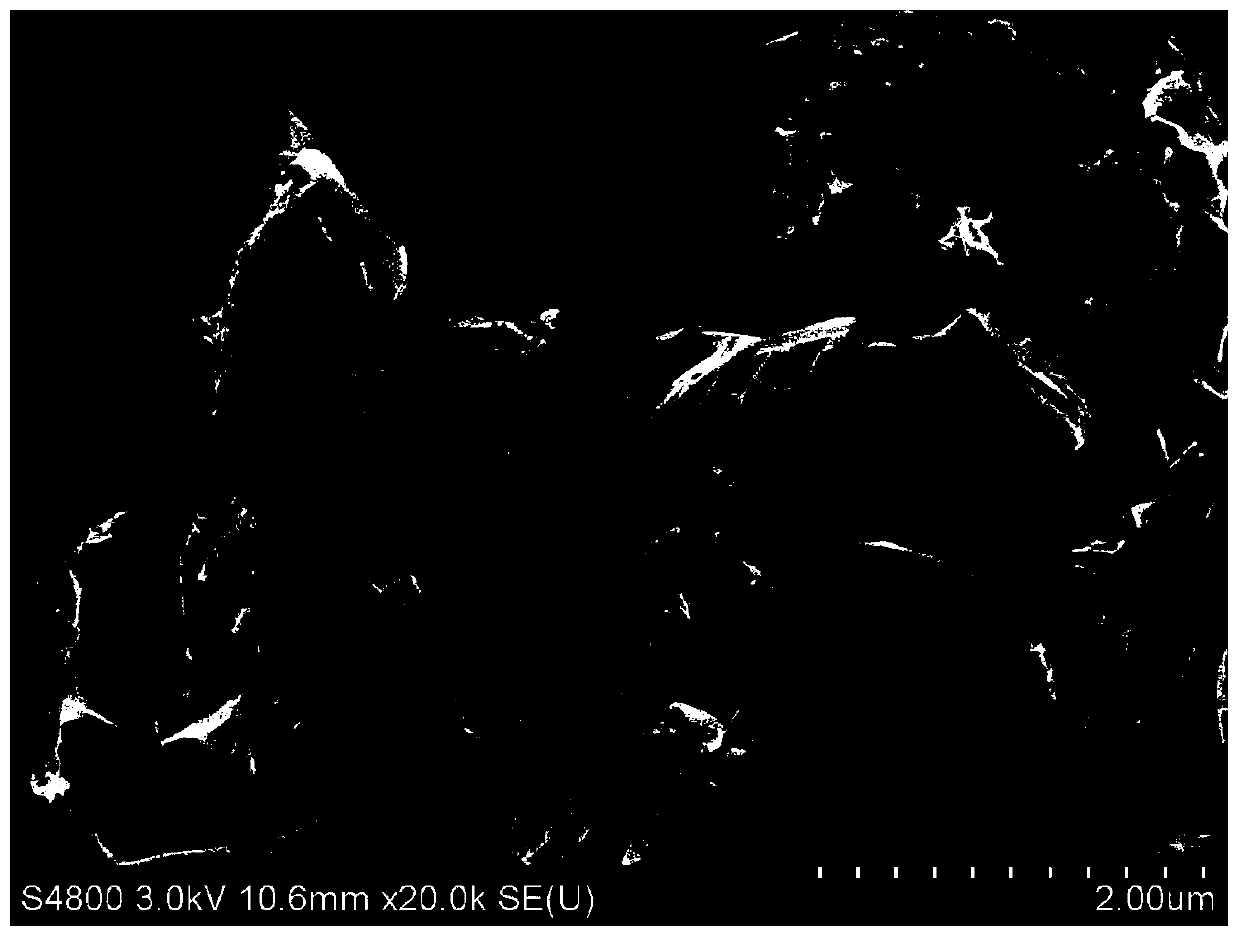

Image

Examples

Embodiment 1

[0044] 1) Add 10mL deionized water into 70mL isopropanol to make 80mL mixed solvent A;

[0045] 2) Add 0.5mL oleylamine and 0.5mL oleic acid into the mixed solvent A according to the volume ratio of 1:1, and stir for 5min to obtain solution B;

[0046] 3) Take 1mmol of CoCl 2 ·6H 2 O, 10mmol of CO(NH 2 ) 2 , according to the molar ratio of 1:10 was added to the solution B, and stirred for 10min to obtain the solution C;

[0047] 4) 0.08g of graphene oxide was added to solution C, and magnetically stirred for 30min to obtain suspension D;

[0048] 5) ultrasonically treat the suspension D for 8 hours;

[0049] 6) Put the ultrasonic suspension D in an oil bath, set the holding temperature to 90°C, and set the holding time to 10h, then naturally cool to room temperature to obtain the precipitate E;

[0050] 7) Centrifuge the precipitate and wash it with absolute ethanol and hexane for 3 times respectively, then put it into a vacuum drying oven for 10 hours at 70°C to obtain ...

Embodiment 2

[0055] 1) Add 5mL deionized water into 75mL isopropanol to make 80mL mixed solvent A;

[0056] 2) Add 1mL oleylamine and 1mL oleic acid into the mixed solvent A according to the volume ratio of 1:1, and stir for 5min to obtain solution B;

[0057] 3) Take 2mmol of CoCl 2 ·6H 2 O, 20mmol of CO(NH 2 ) 2 , according to the molar ratio of 1:10 was added to the solution B, and stirred for 10min to obtain the solution C;

[0058] 4) 0.12g of graphene oxide was added to solution C, and magnetically stirred for 40min to obtain suspension D;

[0059] 5) ultrasonically treat the suspension D for 10 h;

[0060] 6) Put the ultrasonic suspension D in an oil bath, set the holding temperature to 100°C, and set the holding time to 8h, then naturally cool to room temperature to obtain the precipitate E;

[0061] 7) Centrifuge the precipitate and wash it with absolute ethanol and hexane for 4 times, then put it into a vacuum drying oven at 80°C for 8 hours to obtain the precursor F;

[0...

Embodiment 3

[0064] 1) Add 8mL deionized water to 72mL isopropanol to make 80mL mixed solvent A;

[0065] 2) Add 1.5mL oleylamine and 1.5mL oleic acid into the mixed solvent A according to the volume ratio of 1:1, and stir for 8min to obtain solution B;

[0066] 3) Take 3mmol of CoCl 2 ·6H 2 O, 30mmol of CO(NH 2 ) 2 , according to the molar ratio of 1:10 was added to solution B in turn, stirred for 20min to obtain solution C;

[0067] 4) 0.16g of graphene oxide was added to solution C, and magnetically stirred for 50min to obtain suspension D;

[0068] 5) ultrasonically treat the suspension D for 12 hours;

[0069] 6) Put the ultrasonic suspension D in an oil bath, set the holding temperature to 110°C, and set the holding time to 7h, then naturally cool to room temperature to obtain the precipitate E;

[0070] 7) Centrifuge the precipitate and wash it with absolute ethanol and hexane for 5 times respectively, then put it into a vacuum drying oven at 90°C for 6 hours to obtain the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com