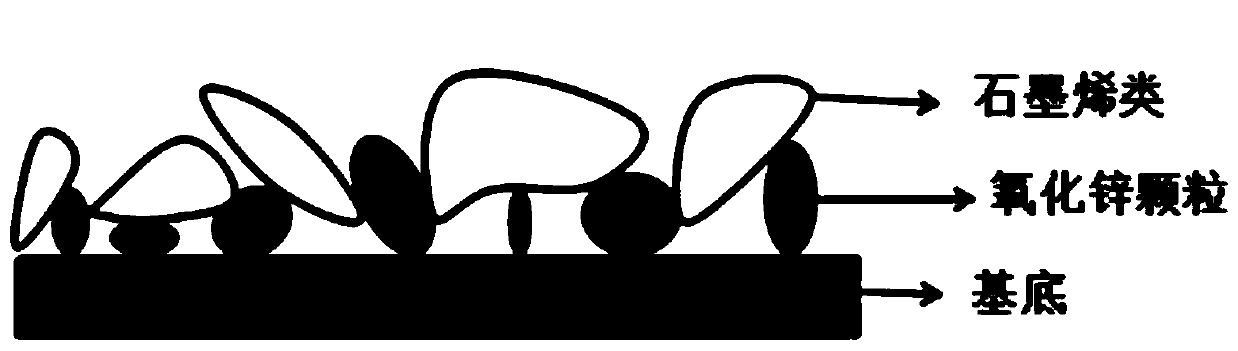

A chromatographic column based on graphene and zinc oxide bilayer film stationary phase and preparation method of stationary phase thereof

A technology of zinc oxide film and graphene, which is applied in the field of chromatographic separation, can solve the problems of graphene-based nano-material application limitations, reduced film adhesion, and increased preparation difficulty, which is conducive to large-scale industrial production and improved stability. The effect of overcoming the lack of universality and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, a silicon-based MEMS micro-gas chromatographic column is used to prepare a stationary phase, and the specific preparation process includes the following steps:

[0032] Step 1: preparation of MEMS miniature chromatographic column;

[0033] The MEMS miniature chromatographic column of this embodiment is a multi-channel column structure of 8 parallel flow channels, the depth of each flow channel is 300 microns, the width is 30 microns, and the ratio of depth to width is 10: 1. This embodiment is specifically The monocrystalline silicon is etched by DRIE process, and then the glass top cover is formed by anodic bonding process. In this implementation, the planar shape of the flow channel is serpentine, and the total length of the flow channel is 0.5 meters.

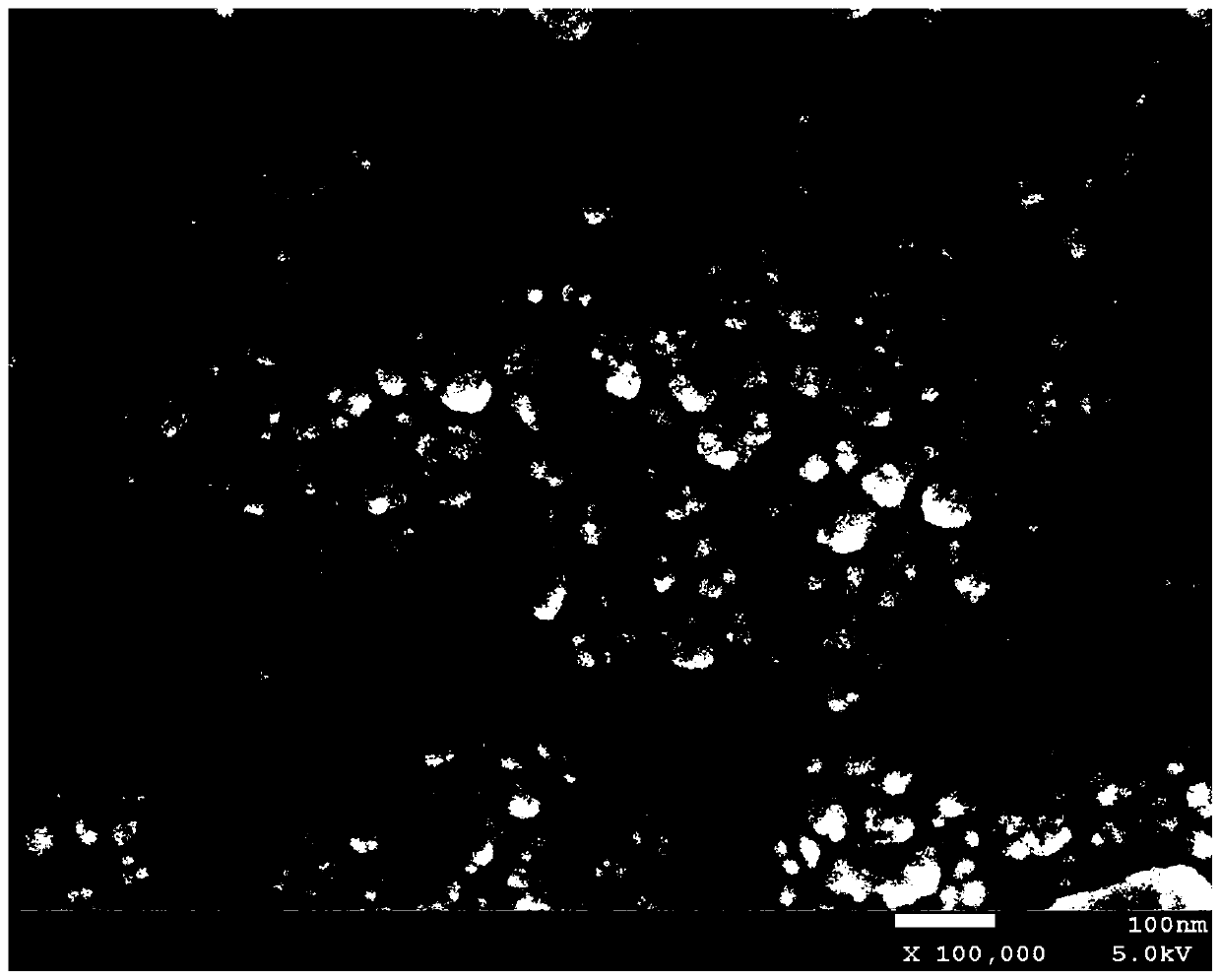

[0034] Step 2: preparing a zinc oxide film;

[0035] According to the general knowledge of those skilled in the art, it can be known that before the stationary phase coating, the silicon-based flo...

Embodiment 2

[0045] This embodiment, as a comparative example, also adopts a silicon-based MEMS micro-gas chromatography column to prepare a stationary phase, and the specific preparation process includes the following steps:

[0046] Step 1: preparation of MEMS miniature chromatographic column;

[0047] The preparation process and specifications of the MEMS micro-chromatographic column in this embodiment are the same as those in Example 1, and will not be repeated here;

[0048] Step 2: preparing reduced graphene oxide film;

[0049] According to the general knowledge of those skilled in the art, it can be known that octamethylsiloxane should be used to inert the silicon-based flow channel before coating the reduced graphene oxide dispersion, and then perform the following operations:

[0050] a). The reduced graphene oxide aqueous solution with a concentration of 0.43wt% is diluted to 0.2wt% with deionized water, and then the diluted solution is ultrasonically treated for 5 minutes to f...

Embodiment 3

[0055] In this embodiment, a quartz capillary liquid chromatography column is used to prepare the stationary phase, and the specific preparation process includes the following steps:

[0056] Step 1: preparing a zinc oxide film;

[0057] a). Dissolve 4.39g of zinc acetate dihydrate in 40mL of absolute ethanol, stir magnetically for 1 hour in a water bath at 60°C, then add 2mL of ethanolamine as a stabilizer and stir for 1 hour, adjust with glacial acetic acid and ammonia water The pH value of the sol is 8;

[0058] b). Standing and aging the prepared zinc oxide sol precursor at room temperature for 72 hours;

[0059] c). Connect the static coating pipeline, pass the zinc acetate solution that has been gelled into the flow channel of the chromatographic column through high-pressure nitrogen, until there are droplets at the gas outlet, and observe that there are no bubbles on the wall of the chromatographic tank, so as to ensure that the gel is completely Coated in the flow ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com