Hydrazine solution special for desulfurizing and denitrifying chimney flue gas and preparation method of hydrazine solution

A desulfurization and denitrification, solution technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as ammonia escape, achieve low ammonia escape rate, low NH3, and suppress volatilization and decomposition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

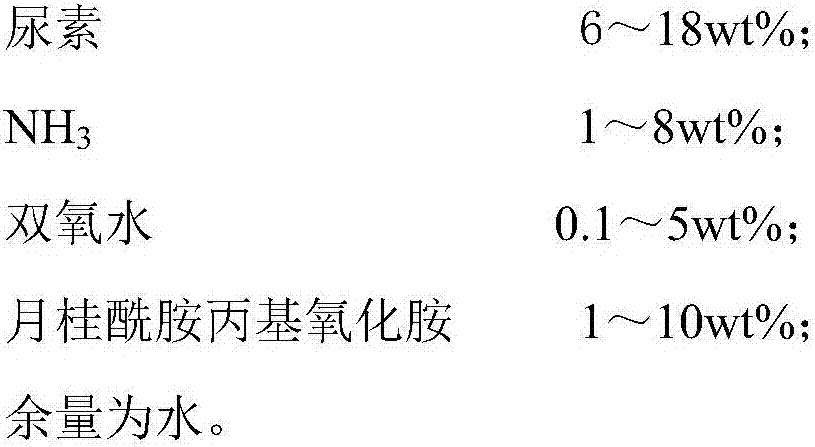

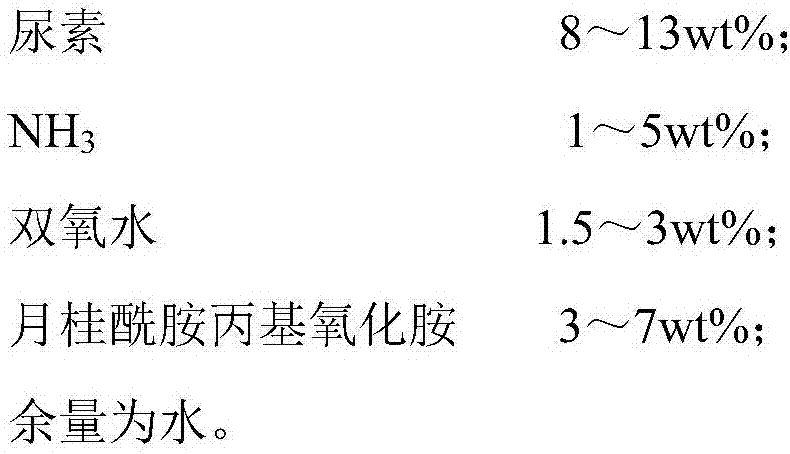

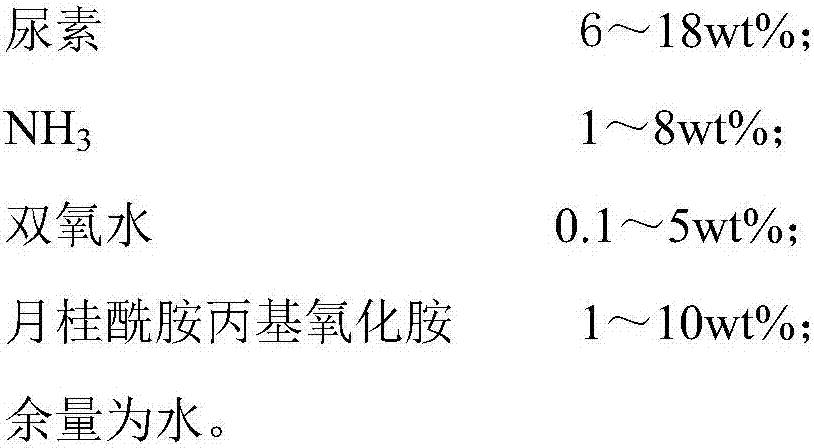

Method used

Image

Examples

Embodiment 1

[0035] Add 0.13 kg of industrial salt to 91 kg of water, and obtain reverse osmosis water after the first-stage reverse osmosis treatment, pass the reverse osmosis water into the synthesis tank through the pipeline, and spray 6 kg of urea in the synthesis tank with an air compressor at room temperature. Steam or electric heating, so that the temperature of the solution in the synthesis tank is 20-35 ° C, start the electric mixer, stir at a rate of 4000 rpm for 30 minutes, and then use NH 3 Spray method to 1kg liquid NH 3 Spray into the synthesis tank, then add 0.1kg hydrogen peroxide, hydrogen peroxide 2 o 2 The content is 27.5wt%, and the obtained solution has a pH of 8. Finally, 1 kg of lauryl amidopropyl amine oxide is added to obtain a hydrazine solution. The solution is naturally cooled for 6 hours and pumped into a storage tank for later use.

Embodiment 2

[0037] Add 0.2kg of industrial salt to 62kg of water, obtain soft water after first-stage reverse osmosis filtration, pass the soft water into the synthesis tank through the pipeline, and spray 16kg of urea in the synthesis tank with an air compressor at room temperature, and use steam or electric heating , so that the temperature of the solution in the synthesis tank is 20-35 ° C, use an electric mixer to stir at a rate of 4000 rpm for 30 minutes, and then use NH 3 Spray method will 7.5kg NH 3 Spray into the synthesis tank, then add 5kg hydrogen peroxide, hydrogen peroxide 2 o 2 The content is 27.5 wt%, and the obtained solution has a pH of 7. Finally, 9 kg of lauryl amidopropyl amine oxide is added to obtain a hydrazine solution. The solution is naturally cooled for 6 hours and pumped into a storage tank for later use.

Embodiment 3

[0038] Embodiment 3 (right end point)

[0039] Add 0.3kg of industrial salt to 85kg of water, obtain soft water after one-stage reverse osmosis filtration, pass the soft water into the synthesis tank through the pipeline, and spray 11.5kg of urea in the synthesis tank with an air compressor at room temperature, use steam or electric After heating so that the temperature of the solution in the synthesis tank is 20-35°C, use an electric mixer to stir at a rate of 4000 rpm for 30 minutes, then use NH 3 Spray method will 5kg NH 3 Spray into the synthesis tank, then add 3kg of hydrogen peroxide, H in hydrogen peroxide 2 o 2The content is 27.5 wt%, and the obtained solution has a pH of 6.8. Finally, 6 kg of lauryl amidopropyl amine oxide is added to obtain a hydrazine solution. The solution is naturally cooled for 6 hours and pumped into a storage tank for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com