Cracking furnace for acetylene production by partial oxidation of natural gas

An oxidation method, natural gas technology, applied in the direction of chemical methods, chemical instruments and methods, dissolution, etc. that make the gas medium react with the gas medium, can solve the problems of fragile equipment, poor cooling effect, complex internal structure, etc., and achieve the overall structure Simple, uniform gas mixing, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

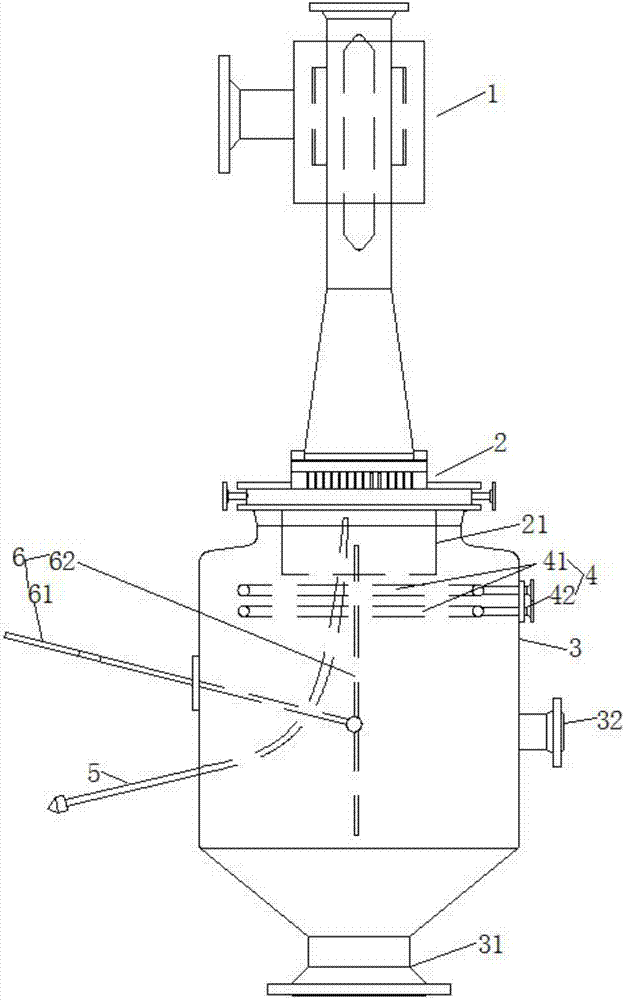

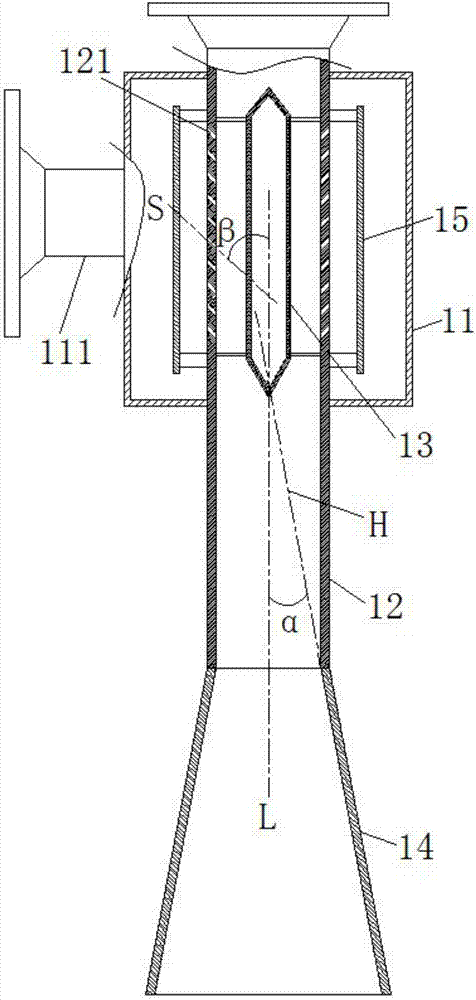

[0059] Example: such as figure 1 As shown, the cracking furnace adopting the partial oxidation of natural gas to produce acetylene of the present embodiment comprises a mixer 1, a burner plate 2, a furnace body 3 and a water quenching device 4;

[0060] The interior of the furnace body 3 is hollow, and the upper end is open;

[0061] The above-mentioned burner plate 2 is sealed and installed on the opening end of the above-mentioned furnace body 3, and its lower end has a gas reaction chamber 21 with an inner hollow and open upper and lower ends, and the above-mentioned gas reaction chamber 21 is located inside the opening end of the above-mentioned furnace body 3;

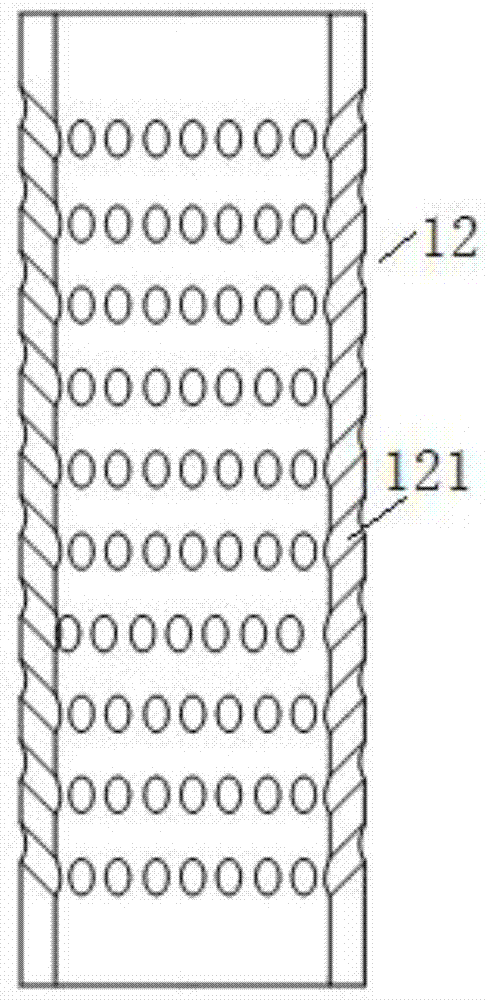

[0062] The above-mentioned mixer 1 is sealed and installed on the upper end of the above-mentioned burner plate 2, and the gas outlet is communicated with the above-mentioned gas reaction chamber 21;

[0063] The water quenching device 4 is arranged in the furnace body 3 and is located below the gas reaction cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com