Production equipment and preparation method of a high-purity clay mineral liquid product

A technology of clay minerals and liquid products, applied in chemical instruments and methods, silicon compounds, sustainable manufacturing/processing, etc., can solve problems such as unreachable dispersion viscosity, product efficacy cannot be displayed, etc., to solve the problem of ineffective dispersion and use Restricted, reduced microstructural disruption, increased viscosity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

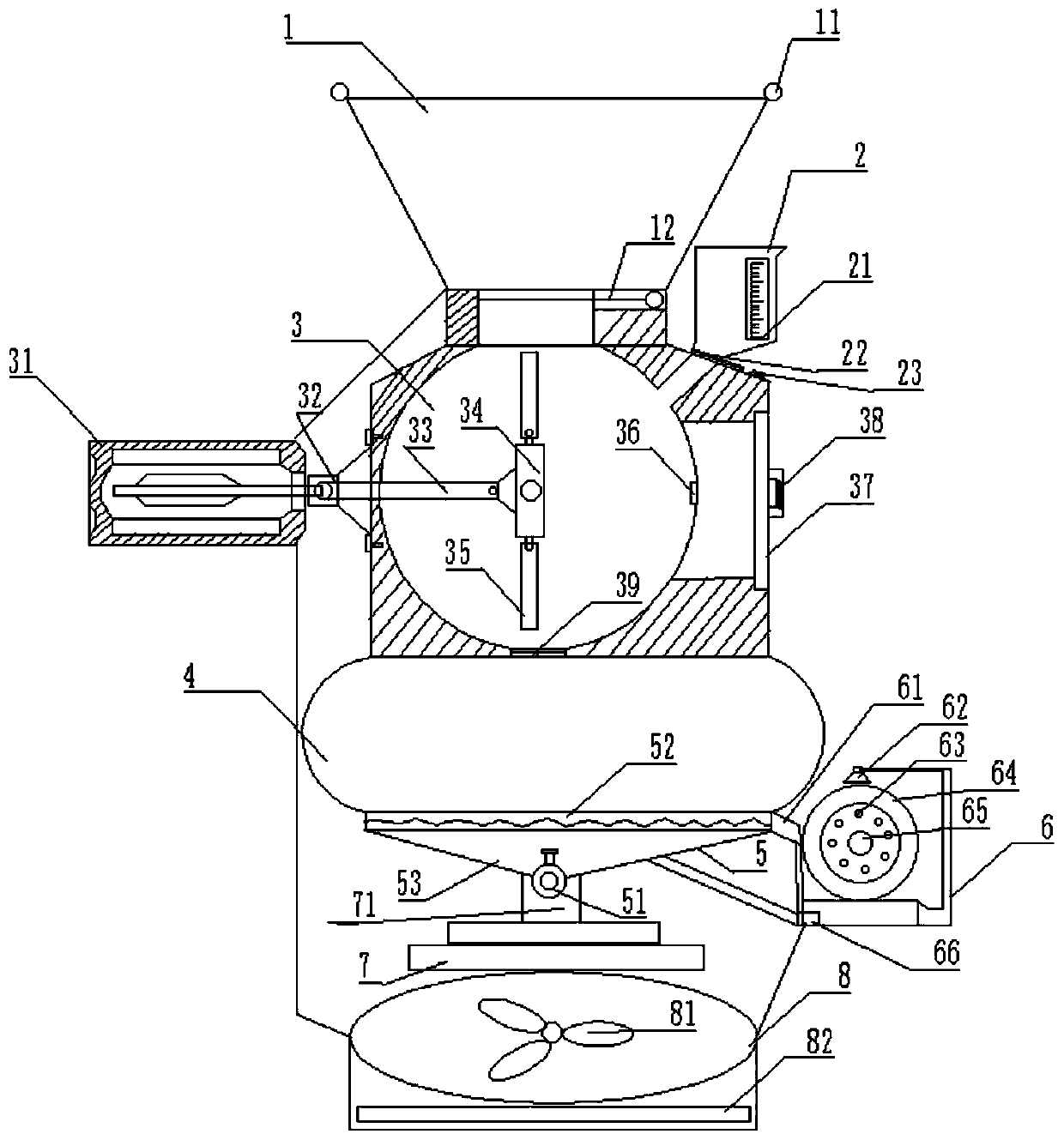

[0029]Embodiment 1: A kind of production equipment of high-purity clay mineral liquid product, production equipment is multi-function mixing material integration device, mainly comprises: solid feeder 1, liquid feeder 2, mixer 3, precipitator 4, filter 5. Rolling device 6, centrifuge 7, reaction kettle 8, solid feeder 1 and liquid feeder 2 are fixed above the mixer 3 by screws, the bottom of the mixer 3 is connected to the settler 4, and the settler 4 The bottom of is connected with filter 5;

[0030] The four edges of the top of the solid feeder 1 are provided with four corner rollers 11, which are used for non-slip fixing during feeding. The bottom of the solid feeder 1 is provided with a weighing device 12, which weighs the solid material in real time, and the liquid feeding A liquid level scale 21 is provided on the side wall of the device 2, and a flow meter 22 is provided at the position where the liquid feeder 2 is connected to the mixer 3, so as to control the flow of ...

Embodiment 2

[0036] Embodiment 2: A kind of production equipment of high-purity clay mineral liquid product, the production equipment is a multifunctional mixing integrated device, mainly comprising: solid feeder 1, liquid feeder 2, mixer 3, precipitator 4, filter 5. Rolling device 6, centrifuge 7, reaction kettle 8, solid feeder 1 and liquid feeder 2 are fixed above the mixer 3 by screws, the bottom of the mixer 3 is connected to the settler 4, and the settler 4 The bottom of is connected with filter 5;

[0037] The four edges of the top of the solid feeder 1 are provided with four corner rollers 11, which are used for non-slip fixing during feeding. The bottom of the solid feeder 1 is provided with a weighing device 12, which weighs the solid material in real time, and the liquid feeding A liquid level scale 21 is provided on the side wall of the device 2, and a flow meter 22 is provided at the position where the liquid feeder 2 is connected to the mixer 3, so as to control the flow of t...

Embodiment 3

[0043] Embodiment 3: A kind of production equipment of high-purity clay mineral liquid product, the production equipment is a multifunctional mixing integrated device, mainly comprising: solid feeder 1, liquid feeder 2, mixer 3, precipitator 4, filter 5. Rolling device 6, centrifuge 7, reaction kettle 8, solid feeder 1 and liquid feeder 2 are fixed above the mixer 3 by screws, the bottom of the mixer 3 is connected to the settler 4, and the settler 4 The bottom of is connected with filter 5;

[0044] The four edges of the top of the solid feeder 1 are provided with four corner rollers 11, which are used for non-slip fixing during feeding. The bottom of the solid feeder 1 is provided with a weighing device 12, which weighs the solid material in real time, and the liquid feeding A liquid level scale 21 is provided on the side wall of the device 2, and a flow meter 22 is provided at the position where the liquid feeder 2 is connected to the mixer 3, so as to control the flow of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com