Method for extracting tannin from shaniodendron subaequalum

A technology of silver hazel and tannin, applied in chemical instruments and methods, pharmaceutical formulations, preparations for skin care, etc., to achieve the effects of short extraction time, high extraction rate, and resistance to biological oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

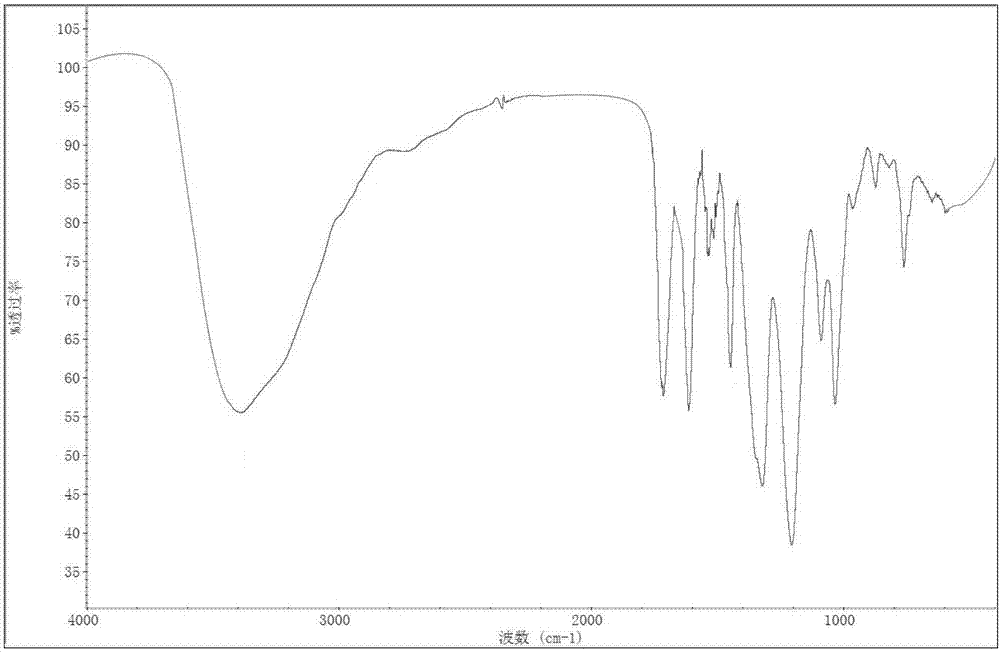

Image

Examples

Embodiment 1

[0032] A method of extracting tannins, extracting tannins from silver hazel.

[0033] A described method for extracting tannins from Silver Hazel, the method steps are as follows:

[0034] a) Extraction: After drying and constant weight, crush the silver hazel leaves, 1.000g, crush, add a little liquid nitrogen, grind into powder in a grinder, add 80% ethanol, extract under microwave heat reflux, combine the extracts, and centrifuge , take the supernatant, and separate it through a vacuum distillation device to obtain a tannin extract;

[0035] b) In step a), the tannin extract is removed with a macroporous resin, first eluting 6 column volumes with 10% ethanol, then eluting 10 column volumes with 75% ethanol, collecting the 75% ethanol eluate, and reducing Press and concentrate to obtain 75% ethanol eluate extract;

[0036] c) 75% ethanol eluting extract in step b) is separated with normal phase silica gel, and the dichloromethane-methanol gradient with a volume ratio of 80...

Embodiment 2

[0052] A method of extracting tannins, extracting tannins from silver hazel.

[0053] A described method for extracting tannins from Silver Hazel, the method steps are as follows:

[0054] a) Extraction: After drying and constant weight, crush the silver hazel leaves, 3.0000g, crush, add a little liquid nitrogen, grind into powder in a grinder, add 90% ethanol, extract under microwave heat reflux, combine the extracts, and centrifuge , take the supernatant, and separate it through a vacuum distillation device to obtain a tannin extract;

[0055] b) In step a), the tannin extract is removed with a macroporous resin, first eluting 6 column volumes with 10% ethanol, then eluting 10 column volumes with 75% ethanol, collecting the 75% ethanol eluate, and reducing Press and concentrate to obtain 75% ethanol eluate extract;

[0056] c) 75% ethanol eluting extract in step b) is separated with normal phase silica gel, and the dichloromethane-methanol gradient with a volume ratio of 8...

Embodiment 3

[0066] A method of extracting tannins, extracting tannins from silver hazel.

[0067] A described method for extracting tannins from Silver Hazel, the method steps are as follows:

[0068] a) Extraction: After drying and constant weight, crush the silver hazel leaves, 1.3680g, pulverize, add a little liquid nitrogen, grind into powder in a grinder, add 85% ethanol, extract under microwave heat reflux, combine the extracts, and centrifuge , take the supernatant, and separate it through a vacuum distillation device to obtain a tannin extract;

[0069] b) In step a), the tannin extract is removed with a macroporous resin, first eluting 6 column volumes with 10% ethanol, then eluting 10 column volumes with 75% ethanol, collecting the 75% ethanol eluate, and reducing Press and concentrate to obtain 75% ethanol eluate extract;

[0070] c) 75% ethanol eluting extract in step b) is separated with normal phase silica gel, and the dichloromethane-methanol gradient with a volume ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com