Method for preparing snow melting and ice inhibiting functional material from saponated residue

A technology of functional materials and saponification residues, applied in the field of preparation of new functional materials, can solve the problem of late start of research on anti-icing pavement, achieve good snow removal and ice suppression, easy to popularize and mass production, and realize resource recovery and utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

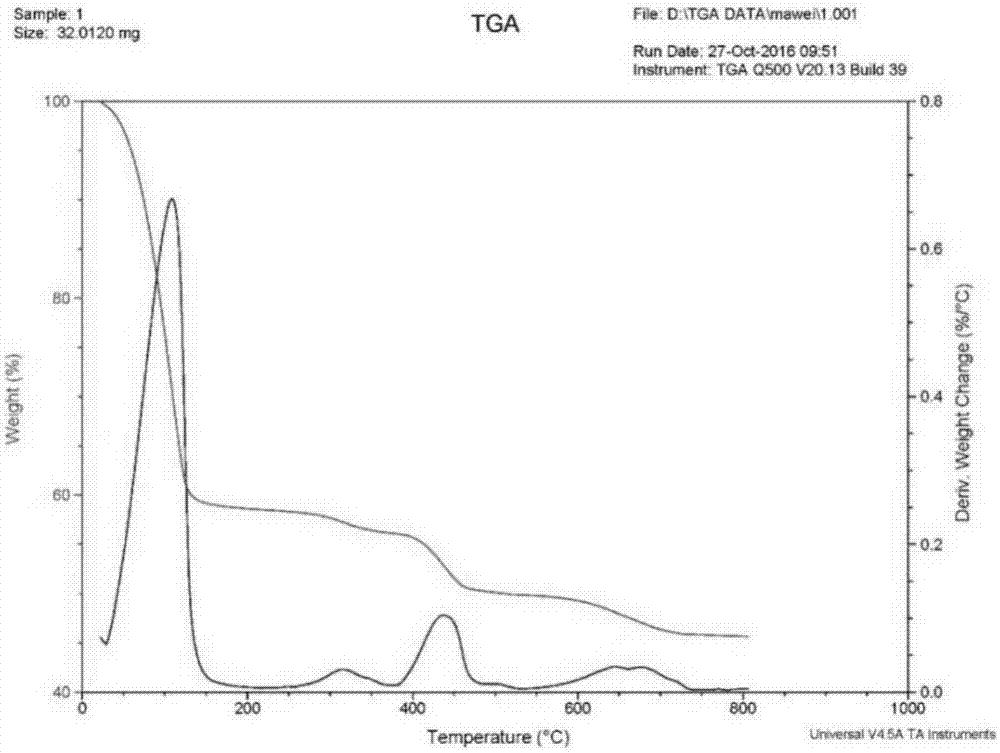

[0036] 1) The specific results of physical and chemical analysis of saponified slag are shown in the table below and attached figure 1 , as shown in the table below, the saponified slag contains a large amount of compounds such as calcium, magnesium, aluminum and iron salts. These compounds all have the effect of lowering the freezing point, and the freezing point lowering material can be obtained through subsequent activation treatment.

[0037] Element number

element

1

1

CaO

69.46

2

MgO

11.83

3

SiO 2

7.254

4

Cl

6.174

5

Fe 2 o 3

2.474

6

al 2 o 3

1.861

7

SO 3

0.43

8

TiO 2

0.125

9

MnO

0.108

10

K2O

0.088

11

SrO

0.075

12

P 2 o 5

0.063

13

Na 2 o

0.045

14

CuO

0.008

15

ZnO

0.005

16

ZrO 2

-

17

NiO

-

[0038] Table 1 Saponifica...

Embodiment 2

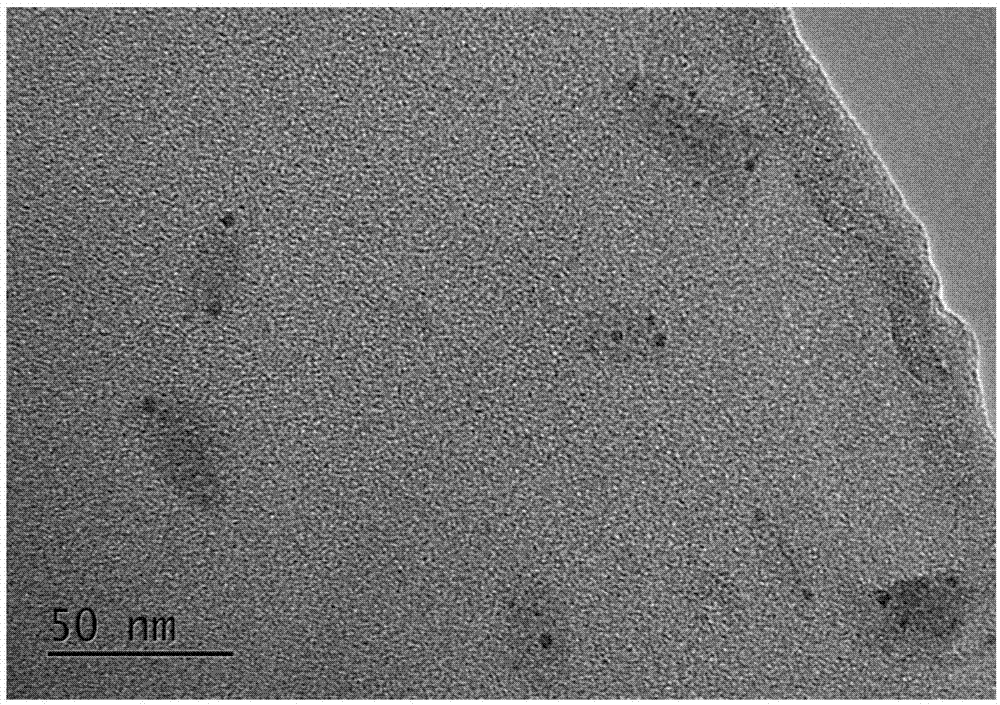

[0049] 1) Weigh 5 g of the insoluble slag M obtained by filtration in Example 1, add 0.5 g of silicon dioxide, and perform mechanical ball milling at a speed of 1000 rpm for 5 h to obtain a silicon-modified solid material M-1.

[0050] 2) Weigh 0.1 g of stearic acid, heat and melt to obtain a stearic acid solution.

[0051] 3) Weigh 1 g of the solid material M-1 obtained by ball milling in step 1), add it into 100 mL of water, and stir to obtain a suspension of M-1.

[0052] 4) Slowly add the stearic acid solution obtained in step 2) to the M-1 suspension obtained in step 3), heat to 80°C, heat and stir for 1 hour to obtain the grafted modified deicing agent solid M- 1 suspension.

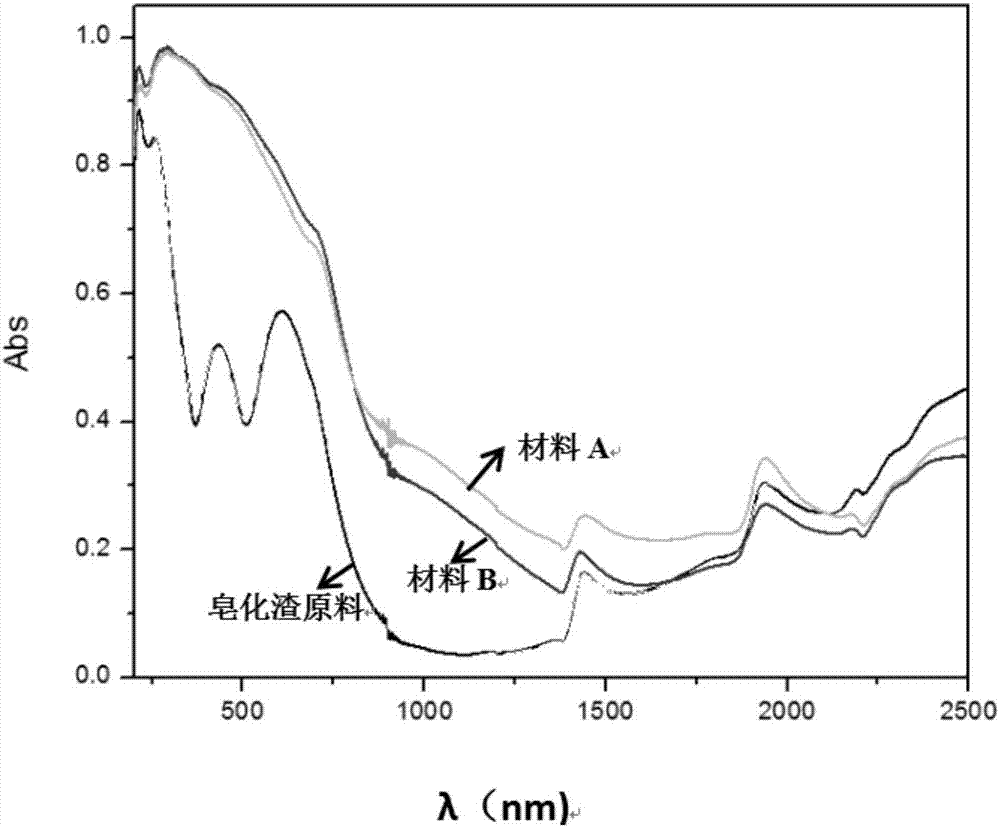

[0053] 5) Filter the snow-melting agent solid M-1 suspension obtained in step 4) to obtain the snow-melting and ice-suppressing material B, and the contact angle characterization data is shown in the appendix Figure 4 .

Embodiment 3

[0055] 1) According to the dosage of 10-200g / m 2 The snow-melting and ice-suppressing material A obtained in Example 1 and the snow-melting and ice-suppressing material B obtained in Example 2) were sprinkled on the simulated road surface to carry out the snow-melting and ice-suppressing test. The comparative example is the icing condition of ordinary road surface, see the attached Figure 5 .

[0056] 2) The specific test results are shown in the following table. It can be seen from the following table that the prepared snow-melting and deicing materials A and B have a freezing point lower than -20°C, which can effectively suppress deicing and melting snow independently. It has a high anti-corrosion ability, and the final plant test results show that its salinity and toxicity are lower than ordinary deicing agents.

[0057] Table 2 Results of snow melting and ice suppression

[0058] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com