A Limoncello That Reduces Liver Damage

A technology of limoncello and liver damage, applied in the preparation of alcoholic beverages, methods based on microorganisms, microorganisms, etc., can solve the problems of destroying the health care effect of raw materials, complicated preparation methods, low alcohol concentration, etc., and achieve low production costs and preparation The method is simple and the effect of liver damage is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 60kg of fresh lemon fruit, wash and crush it, add 60kg of water, heat to 37°C, take 60kg of rice, steam it and mix it with the aforementioned lemon, add 60g of pectinase, 60g of amylase, 60g of cellulase, tannin Enzyme 60g, homogenate, enzymolysis in warm bath at 37°C for 1h, stirring, adjust pH to 4.5, sugar content to 16%. Sterilize by heating at 125°C for 20 minutes. Add 0.01% rhizopus, 0.02% aromatic yeast, 0.02% activated dry yeast, and 0.02% lactic acid bacteria to the sterilized mixture for fermentation. The fermentation time is 20 days. After the fermentation, add 5g of pectinase and 5g of amylase, Cellulase 5g, tannase 5g, keep warm for 60min, filter.

[0021] The obtained filtrate is divided into two parts on average, one part is placed in a cool place and aged for more than 6 months to obtain A1; the other part is conventionally distilled to obtain original wine with a concentration of 70% and left for more than 6 months to obtain AII.

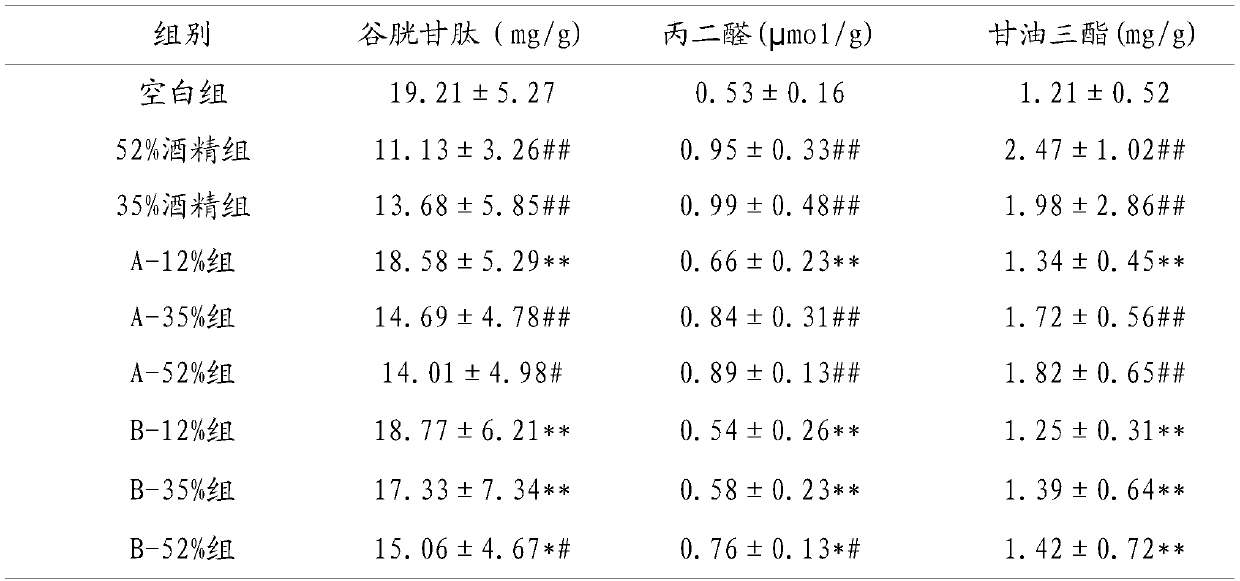

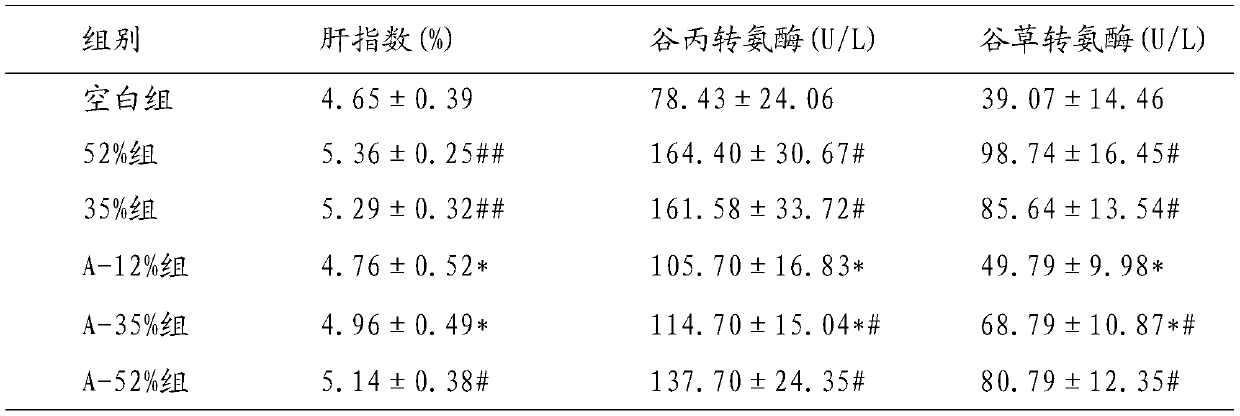

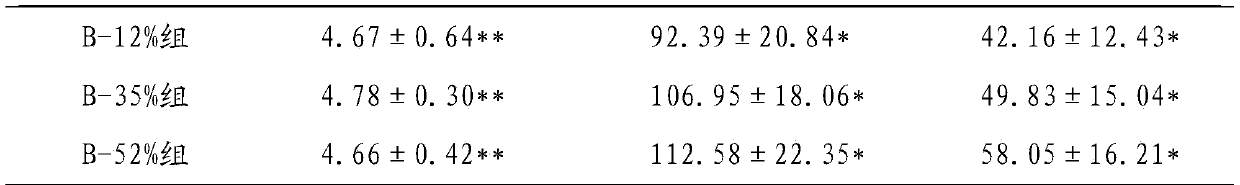

[0022] By blen...

Embodiment 2

[0024] Take 60kg of fresh lemon fruit, add 420 liters of water, reflux in the multi-functional extraction tank for 5 hours, collect the distillate and separate the volatile oil for later use, cool the residue in the tank to 37°C in another tank, take 60 kg of Da Nian, steam it and mix it with the aforementioned lemon Mix evenly, add 60g of pectinase, 60g of amylase, 60g of cellulase, 60g of tannase, homogenate, enzymatically hydrolyze in a warm bath at 37°C for 1 hour, stir, adjust the pH to 4.5, and the sugar content to 16%. Sterilize by heating at 125°C for 20 minutes. Add 0.01% rhizopus, 0.02% aromatic yeast, 0.02% activated dry yeast, and 0.02% lactic acid bacteria to the sterilized mixture for fermentation. The fermentation time is 20 days. After the fermentation, add 5g of pectinase and 5g of amylase, Cellulase 5g, tannase 5g, keep warm for 60min, filter.

[0025] The obtained filtrate is divided into two parts on average, one part is placed in a cool place and aged for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com