A method for selectively separating vanadium, titanium and iron from modified vanadium slag

A selective, vanadium slag technology, applied in the field of metallurgy, can solve problems such as pollution, low efficiency, and high energy consumption, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

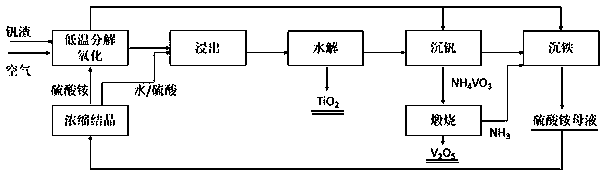

Method used

Image

Examples

Embodiment 1

[0037] (1) Modification of vanadium slag: put the vanadium slag with 17.52% vanadium content, 13.10% titanium content and 36.73% iron content in a water quenching furnace, heat it up to 1450°C for 10 minutes with the furnace, melt and water quench, and obtain modified Vanadium slag;

[0038] (2) Crushing and screening: use a planetary ball mill to crush the modified vanadium slag, and obtain a powder with a diameter of less than 74 μm after screening;

[0039] (3) Mixing: Weigh the raw materials according to the mass ratio of ammonium sulfate: vanadium slag 8:1, and place them in a crucible for mixing;

[0040] (4) Low-temperature activation: put the above-mentioned mixed material in a muffle furnace to raise the temperature to 370°C and keep it warm for 1 hour to obtain molten material and ammonia gas;

[0041] (5) Cooling and miscibility: Place the above molten solid in the air to cool to obtain a massive solid, add the prepared dilute sulfuric acid with a volume concentrat...

Embodiment 2

[0049] (1) Modification of vanadium slag: place vanadium slag with vanadium content of 17.52%, titanium content of 13.10%, and iron content of 36.73% in a water quenching furnace, heat up to 1200°C with the furnace and quickly release and cool to obtain modified vanadium slag;

[0050] (2) Crushing and screening: use a planetary ball mill to crush the modified vanadium slag, and obtain a powder with a diameter of less than 74 μm after screening;

[0051] (3) Mixing: Weigh the raw materials according to the mass ratio of ammonium sulfate: vanadium slag 4:1, and place them in the crucible evenly;

[0052] (4) Low-temperature activation: put the above-mentioned mixed material in a muffle furnace to raise the temperature to 350°C and keep it warm for 30 minutes to obtain molten material and ammonia gas;

[0053] (5) Cooling and miscibility: Place the above molten solid in the air to cool to obtain a massive solid, add the prepared sulfuric acid with a volume concentration of 4% in...

Embodiment 3

[0061] (1) Modification of vanadium slag: place vanadium slag with vanadium content of 17.52%, titanium content of 13.10%, and iron content of 36.73% in a water quenching furnace, heat up to 1600°C with the furnace and quickly release and cool to obtain modified vanadium slag;

[0062] (2) Crushing and screening: use a planetary ball mill to crush the modified vanadium slag, and obtain a powder with a diameter of less than 74 μm after screening;

[0063] (3) Mixing: Weigh the raw materials according to the mass ratio of ammonium sulfate: vanadium slag 6:1, and place them in the crucible evenly;

[0064] (4) Low-temperature activation: Put the above-mentioned mixed material in a muffle furnace at a temperature of 400°C and keep it warm for 30 minutes to obtain molten material and ammonia gas;

[0065] (5) Cooling and miscibility: place the above molten solid in the air to cool to obtain a massive solid, add the prepared sulfuric acid with a volume concentration of 8% into the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com