Method for preparing front electrode of crystalline silicon photovoltaic cell

A photovoltaic cell, front electrode technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of increasing the aspect ratio of the electrode grid line to the screen, the difficulty of increasing the aspect ratio of the electrode grid line, etc., to increase the electrode cross-section. area, improve conversion efficiency, and reduce power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A method for preparing a front electrode of a crystalline silicon photovoltaic cell, comprising printing electrodes, mask plate shielding, ultraviolet light exposure, developing solution cleaning and sintering.

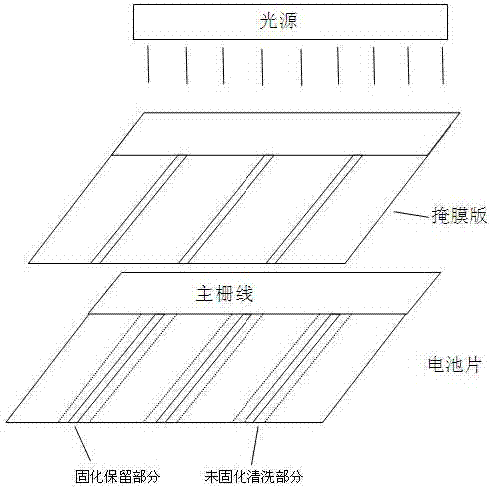

[0022] Such as figure 1 As shown, it specifically includes: the first step, the screen printing photosensitive silver paste is formed into an electrode and dried;

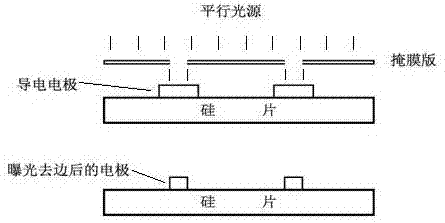

[0023] The second step is to cover the mask plate with the electrode pattern on the top of the battery, and use an ultraviolet light source to irradiate the part that needs to be preserved, and the part that remains is any part of the electrode pattern, and the part that does not need to be retained is uncured and unexposed. The part that needs to be cleaned is any part of the electrode pattern;

[0024] The third step is to use the photosensitive silver paste developer to clean the uncured part of the electrode grid;

[0025] The fourth step is sintering to form electrode grid lines.

[0026] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com