A device and method for extracting micro-plastic in settlings

An extraction device and a technology for microplastics, applied in the field of environmental engineering, can solve the problems of cumbersome and time-consuming extraction, low recovery rate, low efficiency, etc., and achieve the effects of improved elution effect, improved extraction efficiency, and easy removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

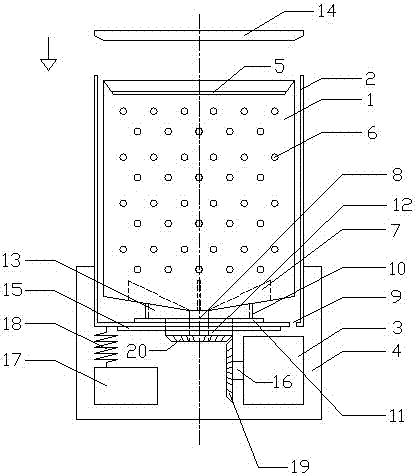

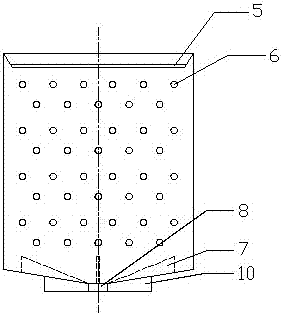

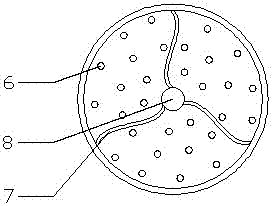

[0056] An extraction device for microplastics in sediments, the structure of which includes a filter cartridge 1, a liquid storage tank 2, a motor 3, a base 4, a mesh screen 5, and a transmission shaft 12; wherein the filter cartridge 1 is installed in the liquid storage tank 2, There is a screen 5 at the top of the filter cartridge 1, the liquid storage tank 2 and the motor 3 are installed on the base 4, and the bottom of the liquid storage tank 2 has a discharge hole 8 connected with the filter cartridge 1; the motor 3 is connected to the transmission shaft through the rotating shaft 16 One end of 12 is joined, and the other end of power transmission shaft 12 passes row hole 8 and joins with the bottom of filter cartridge 1.

[0057] The mesh screen 5 is a circular screen, and the mesh screen 5 is movably connected with the upper opening of the filter cartridge 1 and is detachable.

[0058] The filter cartridge 1 is cylindrical, the side wall and the bottom of the filter car...

Embodiment 2

[0074] A method for extracting microplastics in sediments, the specific steps comprising:

[0075] (1) Dispersion: First mix the sediment sample with the dispersant solution (the dispersant solution is an aqueous solution of potassium metaphosphate or sodium metaphosphate with a concentration of 2.0g / L-5.5 g / L), and then pass through the filter cartridge 1 Filter through the 5.0mm pore size mesh screen 5 on the top mouth and enter the filter cartridge 1, then rinse the screen mesh 5 with a dispersant solution until there is no residue with a particle size of less than 5.0mm, then take out the mesh mesh 5, and then let the motor 3 pass through the rotating shaft 16 drives the filter cartridge 1 to run in both directions. At this time, the impeller 7 on the inner bottom of the filter cartridge 1 also moves accordingly to generate water flows in different directions, thereby promoting the dispersion of solid particles in the sample suspension under the action of fluid shear force;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com