Treatment system for sulfur-containing waste gas and treatment method thereof

A treatment system and waste gas technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of manual detection, cumbersome treatment methods, and imperfect desulfurization process, and achieve the effect of perfect desulfurization process and convenient treatment methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] see Figure 1 to Figure 8 , the present invention provides a technical solution:

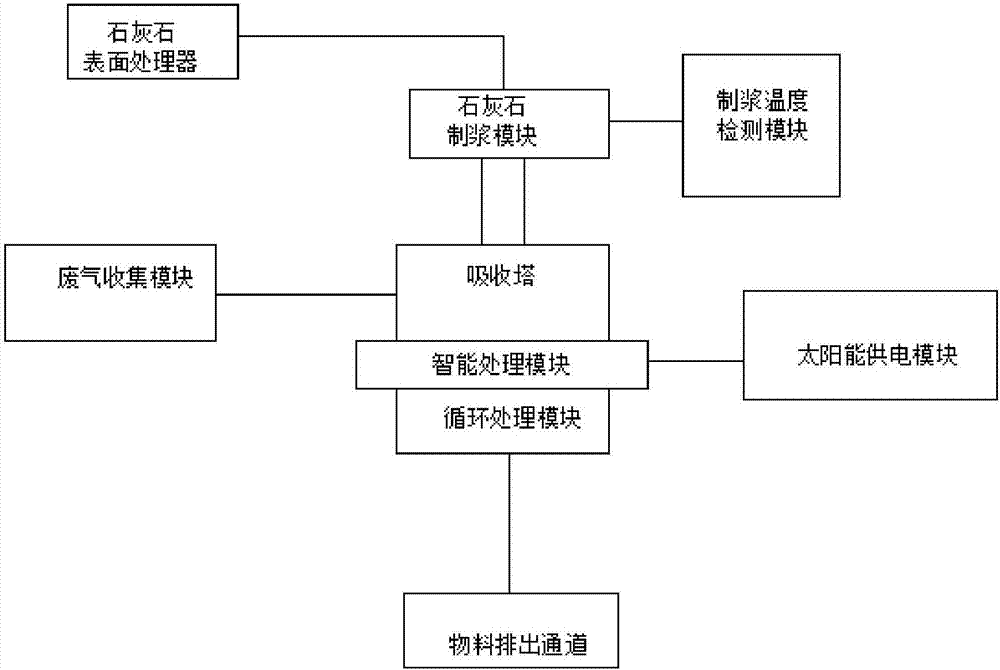

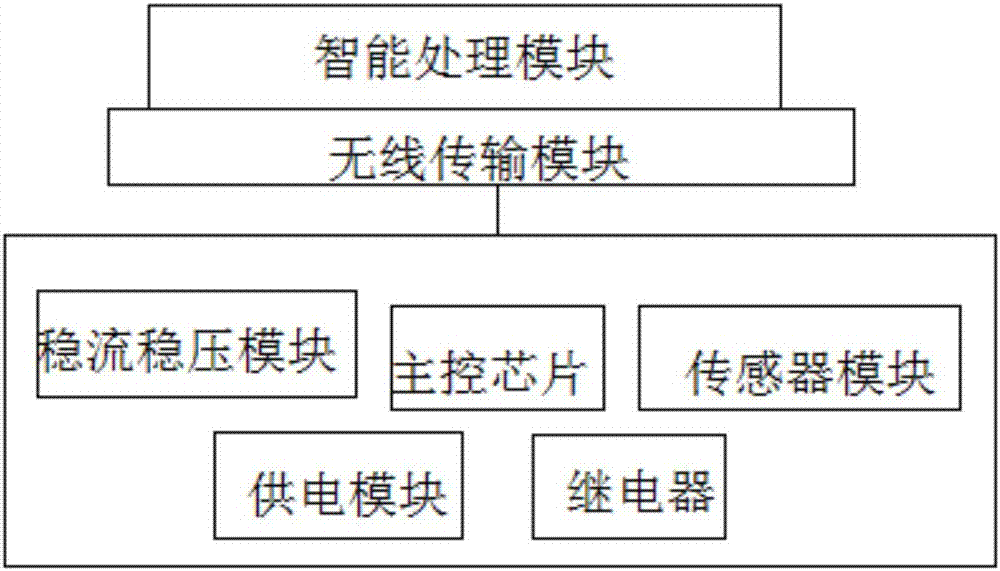

[0037] Such as Figure 1 to Figure 6 , a treatment system for sulfur-containing waste gas, including an absorption tower and a waste gas collection module, the output end of the waste gas collection module is connected with the input end of the absorption tower, and the input end of the absorption tower is also connected with a limestone pulping module through a pipeline The lower end of the absorption tower is connected with a circulation processing module, and an intelligent processing module is installed between the circulation processing module and the absorption tower; the output end of the circulation processing module is connected to the rear material discharge channel;

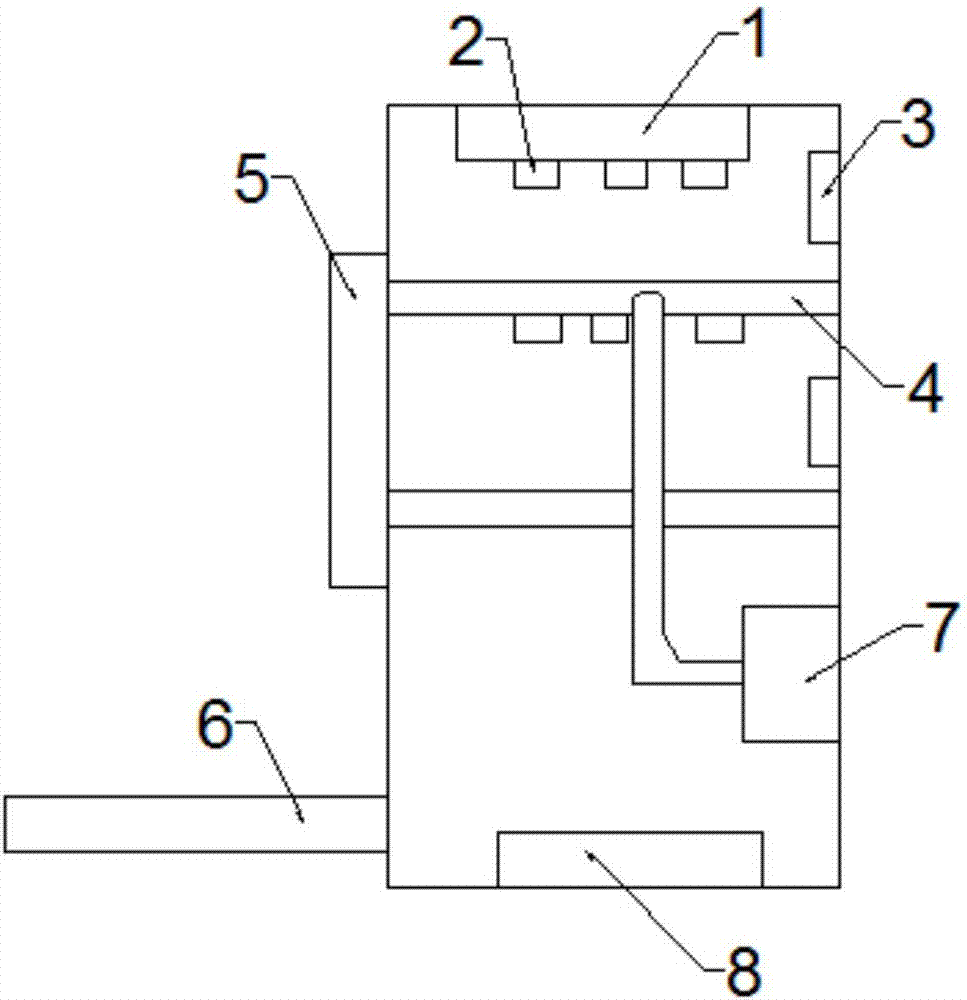

[0038] The absorption tower is a rectangular cylinder, and a circulation pump 1 is installed on the top of the absorption tower, and three shower heads 2 of the same size are installed at the lower end of the cir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap