Process method for denitrification of sintering flue gas using sensible heat of steel slag and effective components

A technology of active components and sintering flue gas, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of sensible heat of steel slag and low utilization rate of active components, and achieve more utilization channels, realization of utilization, and applicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

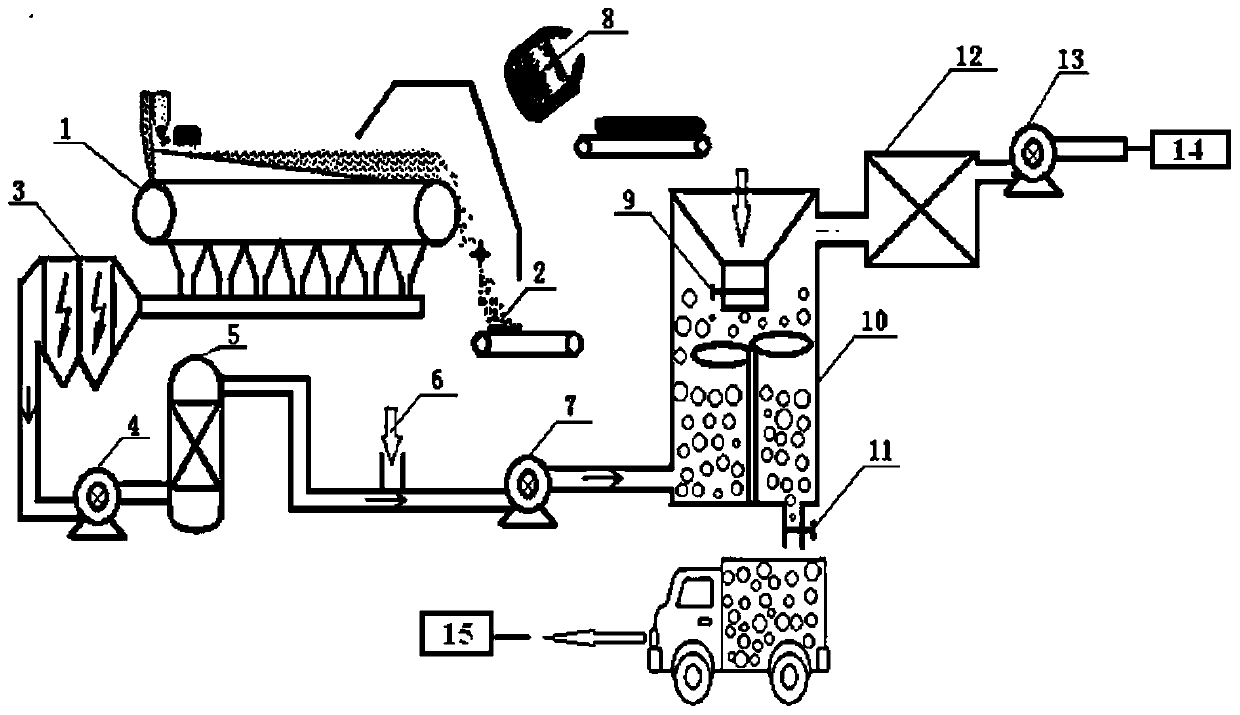

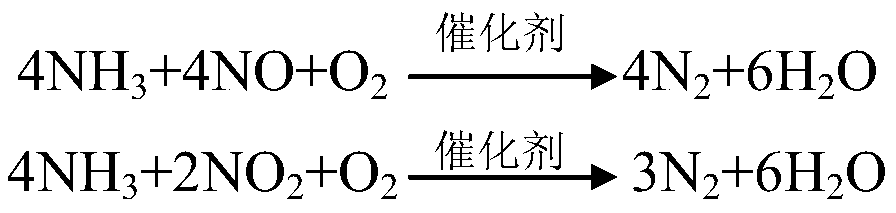

Method used

Image

Examples

Embodiment 1

[0048] The sintering flue gas is discharged from the desulfurization tower after desulfurization, and the temperature of the desulfurization tail gas is 40-60°C, of which NO x The concentration is 300mg / m 3 . The sintering desulfurization tail gas is introduced into the reactor through the induced draft fan, and at the same time, it is uniformly mixed with the ammonia gas at 40-60 °C, and the injection amount of the ammonia gas is 120m 3 / h.

[0049] First pour steel slag one on the top of the denitrification heat exchange reactor, and the slag pouring speed of steel slag one is 2t / min. The bottom end of the steel slag enters the reactor, and after 30 minutes, steel slag II is poured on the top of the denitrification heat exchange reactor. Countercurrent contact denitrification and heat exchange. Among them, the temperature of steel slag is 1450~1500℃, and the main effective components are: CaO: 50%; Fe 2 o 3 : 10%; MnO: 5%; MgO: 8%.

[0050] Reduction, denitrificatio...

Embodiment 2

[0055] The sintering flue gas is discharged from the desulfurization tower after desulfurization, and the temperature of the desulfurization tail gas is 40-60°C, of which NO x The concentration is 400mg / m 3 . The sintering desulfurization tail gas is introduced into the reactor through the induced draft fan, and at the same time, it is uniformly mixed with the ammonia gas at 40-60 °C, and the injection amount of the ammonia gas is 175m 3 / h.

[0056] First pour steel slag 1 on the top of the denitrification heat exchange reactor, and the slag pouring speed of steel slag 1 is 3t / min. The bottom end of the steel slag enters the reactor, and after 35 minutes, the steel slag II is poured on the top of the denitrification heat exchange reactor. The reactor is used for countercurrent contact denitrification and heat exchange with dry granulated steel slag. Among them, the temperature of steel slag is 1500~1650℃, and the main effective components are: CaO: 45%; Fe 2 o 3 : 8%;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com