Resourceful disposal system and method for oil-bearing solid waste microwave heat desorption

A treatment system and thermal desorption technology, applied in the field of oil-containing solid waste microwave thermal desorption recycling treatment system, can solve the problems of uneven temperature distribution, secondary pollution, local coking and carbonization, etc., and achieve efficient thermal desorption process. Improved safety and color clarification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

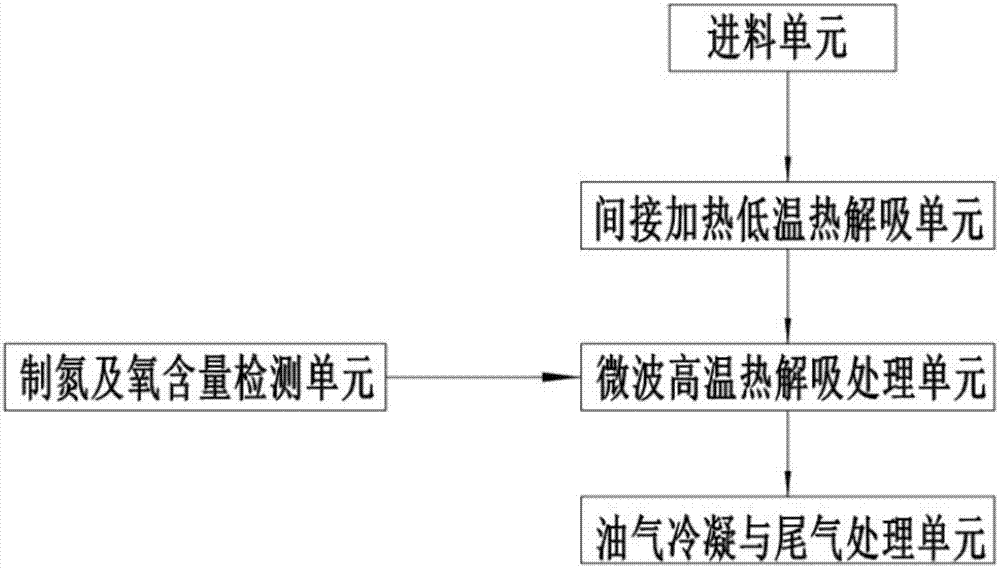

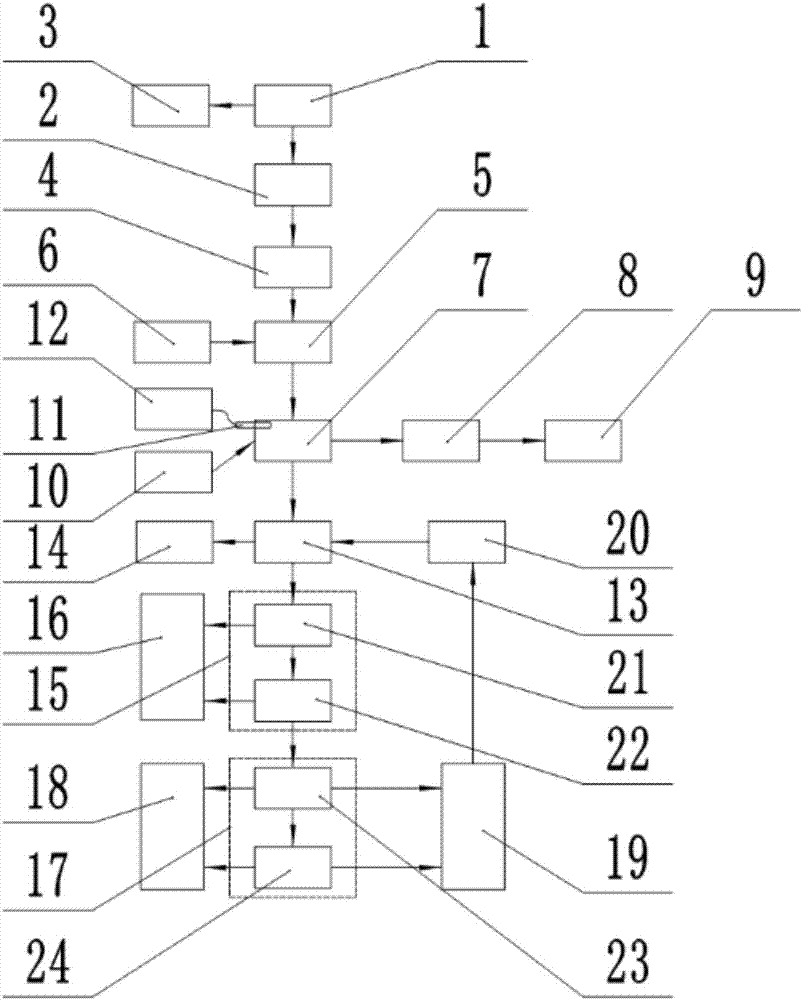

[0035] Such as figure 1 and figure 2 As shown, a microwave thermal desorption resource recovery treatment system for oily solid waste includes a feed unit, an indirect heating low-temperature thermal desorption unit, a microwave high-temperature thermal desorption treatment unit, nitrogen production and oxygen content detection unit, oil and gas condensation and tail gas The processing unit, the feeding unit, the indirect heating low-temperature thermal desorption unit, the microwave high-temperature thermal desorption processing unit and the oil gas condensation and tail gas processing unit are connected in sequence, and the nitrogen production and oxygen content detection unit is connected with the microwave high-temperature thermal desorption processing unit Units are connected.

[0036] The feeding unit includes a vibrating screening feeder 1, the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com