Ketoside solid waste recycling method

A technology for solid waste and treatment method, applied in the field of industrial waste resource utilization, can solve problems such as affecting environmental sanitation, polluting the atmosphere, polluting water bodies, etc., and achieves the effects of reducing pollution, easy operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for recycling ketone glycoside solid waste, comprising the steps of:

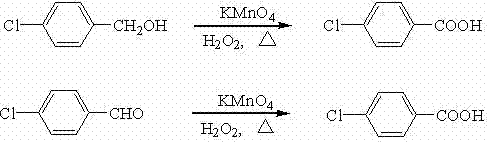

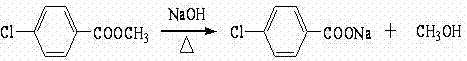

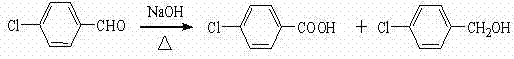

[0026] 1) Add 250 kg of solid waste to a 3000L reactor, then add caustic soda solution (made by dissolving 64Kg sodium hydroxide flake alkali in 2000 L water) and stir until completely dissolved, heat, control the reaction temperature to about 70°C, and react When the pH is 10~11 (about 30min), the reaction solution I is obtained. During the reaction, p-chlorobenzoic acid generates sodium p-chlorobenzoate, and p-chlorobenzaldehyde undergoes disproportionation reaction to generate sodium p-chlorobenzoate, p-chlorobenzyl alcohol, and p-chlorobenzyl alcohol. Methyl benzoate undergoes a hydrolysis reaction to generate sodium p-chlorobenzoate and methanol;

[0027] 2) Control this temperature condition, and under the condition that the degree of vacuum is not greater than -0.09 MPa, distill until no fraction is produced to obtain product II methanol and mother liquor III;

[0028] 3) Add the com...

Embodiment 2

[0032] A method for recycling ketone glycoside solid waste, comprising the steps of:

[0033] 1) Add 70 kg of solid waste to a 1000L reactor, then add caustic soda solution (made by dissolving 20Kg of sodium hydroxide in 600 L of water) and stir until completely dissolved, heat, control the reaction temperature to about 62°C, and react to pH 10~11 (about 25min) to obtain the reaction solution I. During the reaction process, p-chlorobenzoic acid generates sodium p-chlorobenzoate, and p-chlorobenzaldehyde undergoes disproportionation reaction to generate sodium p-chlorobenzoate, p-chlorobenzyl alcohol, and p-chlorobenzoic acid. Methyl ester undergoes hydrolysis reaction to generate sodium p-chlorobenzoate and methanol;

[0034] 2) Under the condition that the degree of vacuum is not greater than -0.09 MPa, distill at about 70°C until no fraction is produced to obtain product II methanol and mother liquor III;

[0035] 3) Add the composite oxidant (the amount of the composite ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com