A high-strength, high-conductivity, heat-resistant copper alloy material and preparation method thereof

A copper alloy, high-conductivity technology, applied in the field of copper alloy processing, can solve the problems of difficult composition stabilization control, poor performance uniformity, easy burning of Zr elements, etc. The effect of forming and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

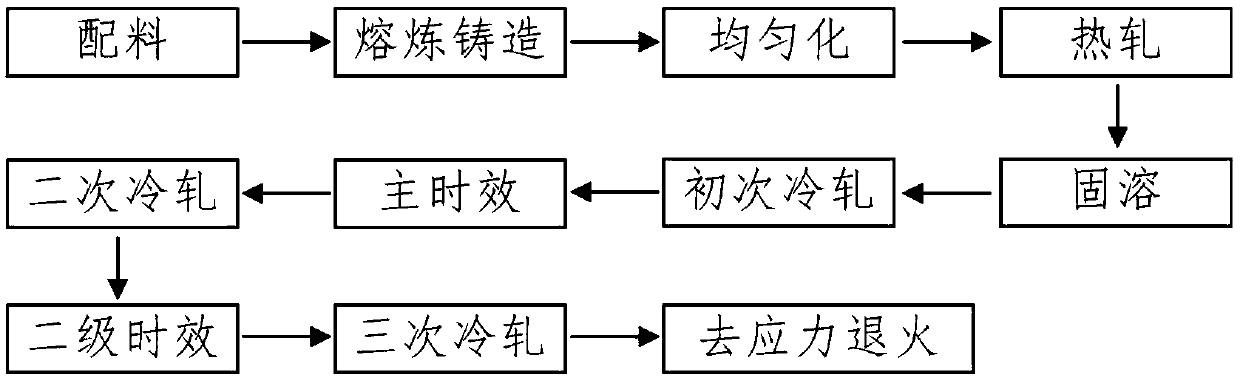

Method used

Image

Examples

Embodiment 1

[0034] According to the composition of the alloy, it is Cr 0.36wt%, Mg 0.05wt%, Si 0.09wt%, Ni 0.05wt%, Cu99.45wt%, and the covering agent is added, mixed evenly, put into the induction melting furnace, and then in the atmosphere Melting is carried out at a temperature of 1300°C, the covering agent is added again when the metal starts to melt, and mechanical stirring is carried out. After the smelting is completed and the slag is removed, a copper alloy melt with uniform and stable composition is obtained.

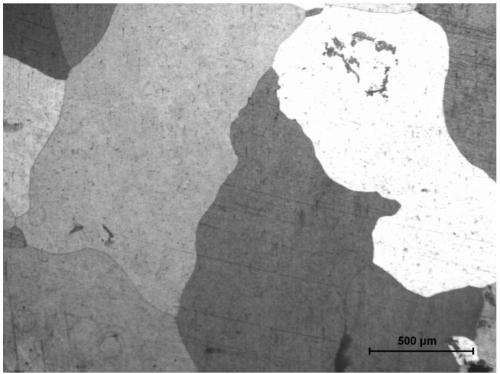

[0035] The copper alloy melt is cast at a temperature of 1250°C, and after air cooling, it is subjected to a homogenization annealing treatment for 8 hours under a protective atmosphere and a temperature of 980°C to obtain a homogenized copper-chromium alloy ingot. Such as figure 2 shown. It can be seen from the figure that the internal structure of the ingot is uniform and there is no obvious second phase.

[0036] The homogenized copper-chromium alloy ingot is cooled ...

Embodiment 2

[0041] According to the composition of the alloy: Cr 0.26wt%, Mg 0.17wt%, Si 0.03wt%, Ni 0.03wt%, Ce0.1wt%, Cu 99.41wt%, add the covering agent, mix well and put it into the induction melting furnace , followed by smelting in the atmosphere and at a temperature of 1300°C. When the metal starts to melt, the covering agent is added again and mechanically stirred. After the smelting is completed and the slag is removed, a copper alloy melt with uniform and stable composition is obtained.

[0042]The copper alloy melt was cast at a temperature of 1280°C, and after air cooling, it was subjected to homogenization annealing treatment for 4 hours in a protective atmosphere at a temperature of 920°C to obtain a homogenized copper-chromium alloy ingot.

[0043] The homogenized copper-chromium alloy ingot is cooled to 850°C with the furnace, and then hot-rolled on an ordinary two-roll mill with a deformation of 50%. After air cooling, a hot-rolled plate is obtained. The hot-rolled sheet ...

Embodiment 3

[0047] According to the composition of the alloy: Cr 0.46wt%, Mg 0.11wt%, Si 0.04wt%, Ni 0.05wt%, Ce0.05wt%, Cu 99.29wt%, add the covering agent, mix well and put it into the induction melting furnace , followed by smelting under atmospheric atmosphere and temperature conditions of 1320°C. When the metal starts to melt, the covering agent is added again and mechanically stirred. After the smelting is completed and the slag is removed, a copper alloy melt with uniform and stable composition is obtained.

[0048] The copper alloy melt was cast at a temperature of 1280°C, and after air cooling, it was subjected to homogenization annealing treatment for 3 hours in a protective atmosphere at a temperature of 950°C to obtain a homogenized copper-chromium alloy ingot.

[0049] The homogenized copper-chromium alloy ingot is cooled to 880°C with the furnace, and then hot-rolled on an ordinary two-roll rolling mill with a deformation of 70%. After air-cooling, a hot-rolled plate is obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com