Degradable and extratracheal outer suspending support and indirect 3D printing method thereof

A hanging bracket and 3D printing technology, applied in brackets, 3D object support structures, additive manufacturing, etc., can solve problems such as harmfulness to the human body, large surface roughness, and insufficient strength, and achieve the effect of good compactness and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

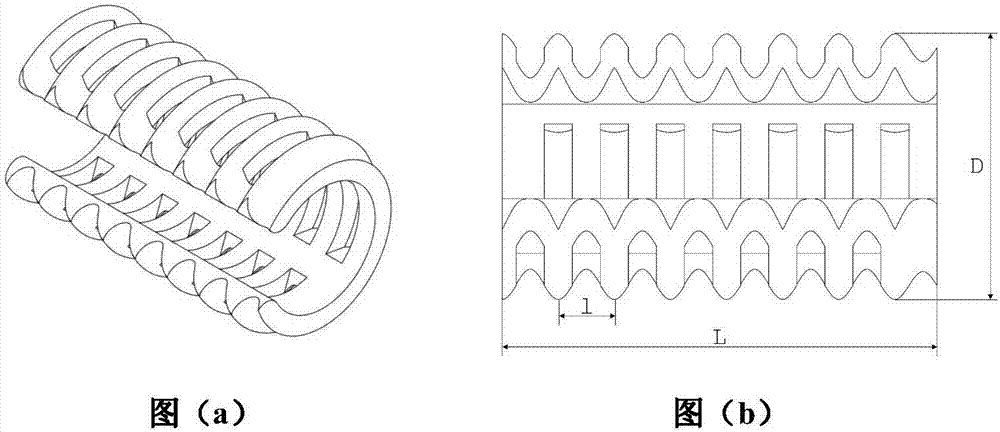

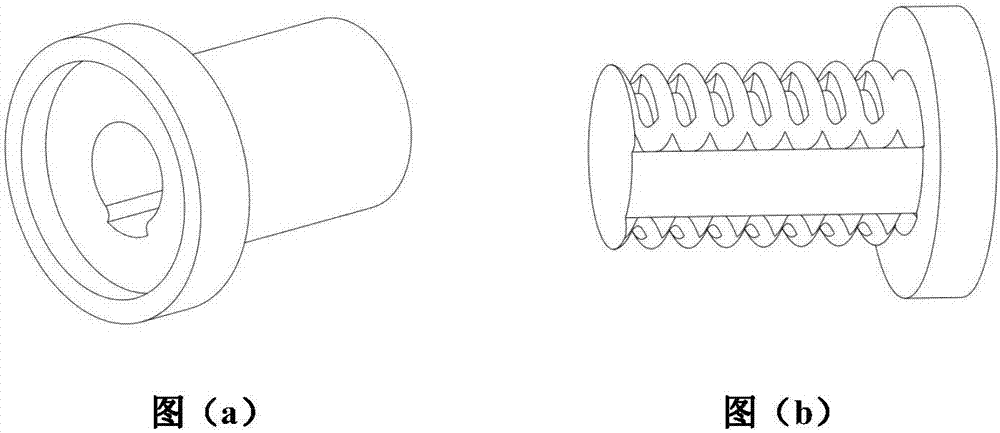

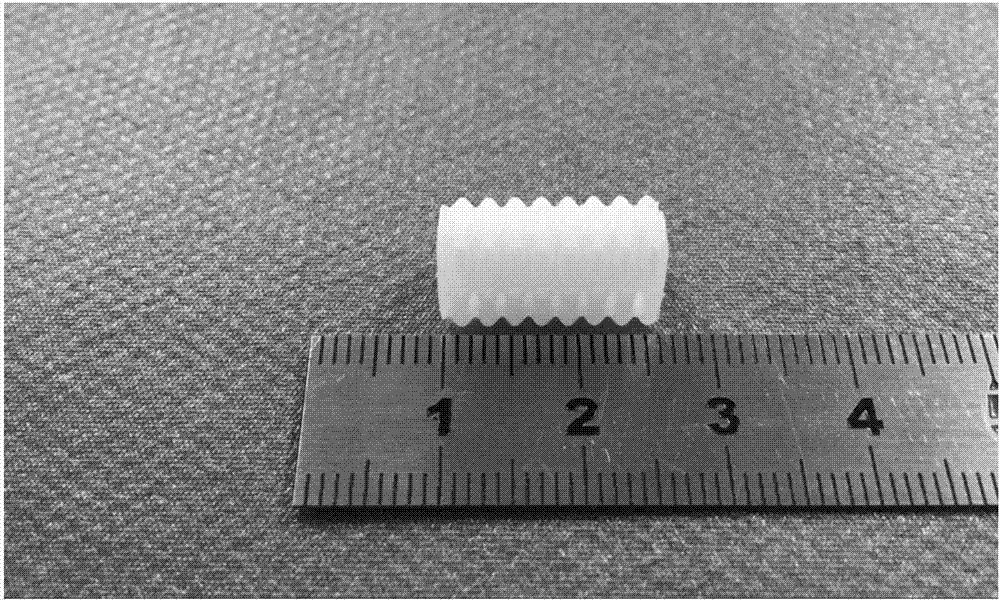

Embodiment 1

[0020] refer to figure 1 , a degradable trachea external suspension bracket, which is an array of several C-shaped cylindrical ring structures, each C-shaped cylindrical ring structure, that is, a three-quarter cylindrical ring structure, the opening angle of the ring is 90°, and the inner diameter of the C-shaped cylindrical ring is is 10.5mm, the outer diameter D is 12mm, the difference between inner and outer diameters, that is, the thickness of the ring is 1.5mm, and the total length L of the C-shaped cylindrical ring structure is 16mm. The specific data are determined by the patient's CT data; each C-shaped cylindrical ring structure The width I of the stent is 2 mm, and its surface is arc-shaped, so that the stent as a whole presents a convex and concave undulating structure; on the C-shaped cylindrical ring structure, through holes are drilled at intervals of 90° on the convex structure, and the stenosis will be narrowed during the operation. The trachea is sutured to t...

Embodiment 2

[0028] A degradable trachea external suspension bracket, which is an array of several C-shaped cylindrical ring structures, each C-shaped cylindrical ring structure, that is, a three-quarter cylindrical ring structure, the opening angle of the ring is 90°, and the inner diameter of the C-shaped cylindrical ring is 13mm, the outer diameter D is 14mm, the difference between the inner and outer diameters, that is, the thickness of the ring is 1mm, the total length L of the C-shaped cylindrical ring structure is 12mm, and the specific data are determined by the CT data of the patient; the width I of each C-shaped cylindrical ring structure 2mm, and its surface is arc-shaped, so that the stent as a whole presents a convex and concave undulating structure; on the C-shaped cylindrical ring structure, through holes are drilled at intervals of 90° on the convex structure, and the stenotic trachea and the flexible The above-mentioned through holes of the degraded tracheal suspension brac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com