A method for dual utilization of low-grade magnesite magnesium and carbon

A magnesite, low-grade technology, applied in chemical instruments and methods, magnesium halide, magnesium chloride, etc., can solve the problems of low comprehensive utilization of resources and restoration of vegetation in mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

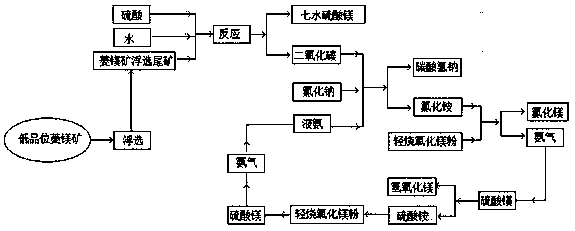

Method used

Image

Examples

Embodiment approach

[0043] (1) Weigh 100g of low-grade magnesite flotation tailings powder, pour it into a 500ml beaker together with 300ml of deionized water, stir well, pour it into a 500ml three-necked flask, and measure the concentrated sulfuric acid with a graduated cylinder Take 100 ml, dilute to 50% (mass ratio), start stirring at 300 rpm, heat up to 85°C-120°C, and react for 2-5 hours.

[0044] (2) Carbon dioxide is passed into an aqueous solution containing 60 grams of sodium chloride and 30 milliliters of ammonia water, and the absorption reaction generates sodium bicarbonate and ammonium chloride.

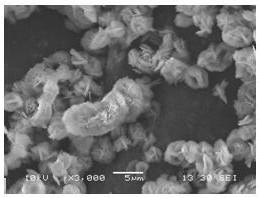

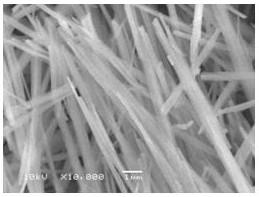

[0045] (3) Dissolve 50 grams of the produced ammonium chloride and 39 grams of lightly burned magnesia powder into a 250 ml three-neck flask, react for 40 minutes at a water bath temperature of 60°C and a stirring speed of 300 r / min, and collect ammonia gas. A clear solution was obtained after suction filtration. Let the clear solution stand at room temperature for 2 days to precipitate wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com