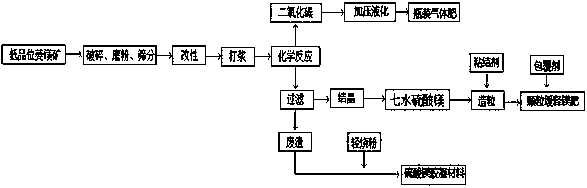

Method for preparing granular slow-release magnesium fertilizer by taking low-grade magnesite as raw material

A magnesite, low-grade technology, applied in the direction of magnesium fertilizer, chemical instruments and methods, magnesium sulfate, etc., can solve the problems of yellowing, affecting plant yield and quality, and achieve the effect of low temperature and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

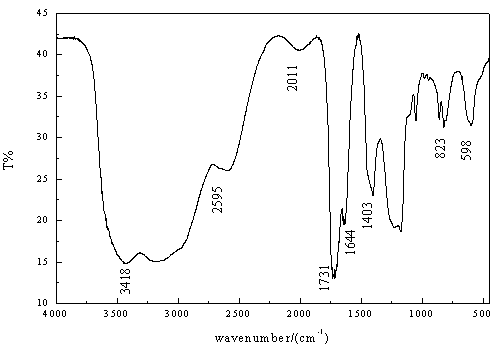

Examples

Embodiment approach

[0034] (1) Weigh 100 grams of low-grade magnesite powder, pour 0.01 grams of surfactant into 100 milliliters of deionized water with a pH value of 11, stir, and modify the surface for 5 minutes.

[0035] (2) The modified magnesite powder is obtained by filtration, and the mother liquor is recycled.

[0036] (3) Pour 100 grams of modified magnesite powder into a 500 ml three-necked flask, measure 100 ml of concentrated sulfuric acid with a measuring cylinder, dilute to 50% (mass ratio), 30 drops / min, and drop into the three-necked flask , start stirring at 300 rpm, heat up to 35°C-85°C, and react for 1 to 3 hours.

[0037] (4) Carbon dioxide, compressed and liquefied.

[0038] (5) Weigh 100g of magnesium sulfate heptahydrate, 0.4, 0.5, and 0.6 g of bentonite, mix them evenly, grind them, place them in a turntable, spray water to make balls, and sieve to make 1-2mm particles Magnesium fertilizer.

[0039] (6) Add a certain amount of maleic anhydride and 200ml of distilled wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com