Ceramic material, preparation method thereof and fluorescent ceramic device

A technology of ceramic materials and raw materials, applied in the field of multifunctional materials, can solve problems affecting projector life and color performance, and achieve the effects of avoiding thermal recession, improving system output brightness, good thermal conductivity and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides a method for preparing the ceramic material described in the above technical solution, which includes the following steps:

[0038] (1) Put Y 2 O 3 , Al 2 O 3 , CeO 2 Mixing with M oxide to prepare a powder raw material; the powder raw material preferably also contains R oxide;

[0039] (2) Pressing the powder raw material into a shape to obtain a green body;

[0040] (3) Sintering the green body to obtain a ceramic material.

[0041] In the present invention, the oxide of R and the oxide of M are the same as the oxide of R and M described in the above technical solution, and will not be repeated here. The present invention provides for the Y 2 O 3 , Al 2 O 3 , CeO 2 The source of the oxide of R and the oxide of M is not particularly limited, and can be purchased commercially, and the purity of each oxide is preferably not less than 99.9%. In the present invention, the Y 2 O 3 , Al 2 O 3 , CeO 2 The dosage ratio of the oxide of R and the oxide of...

Embodiment 1

[0069] Weigh the required high purity Y according to the molar ratio 2.998:4.95:0.002:0.001:0.1 2 O 3 , Al 2 O 3 , CeO 2 , La 2 O 3 And SiO 2 , Its purity is not less than 99.9%, and then use absolute ethanol as the ball milling medium, high-purity alumina ball as the grinding ball, tetraethylorthosilicate as the sintering aid, polyethylene glycol 400 as the dispersing agent, in the planetary type High-speed ball milling in the ball mill. After ball milling, it is dried, ground, and sieved to obtain sub-micron high-purity powder. The powder is calcined at 750°C for 1 hour to remove residual organic matter. After calcination, it is sieved again to obtain sub-micron high-purity ultrafine powder. raw material.

[0070] Uniaxial compression molding of the obtained ultrafine powder raw material, and then use 250MPa cold isostatic pressing to obtain a green sheet with certain strength;

[0071] Put the obtained green sheet into an atmosphere furnace for sintering at 1600°C for 10 hours,...

Embodiment 2

[0077] The ceramic material is prepared according to the method described in Example 1. The difference from Example 1 is that the molar ratio of 2.98:4:0.02:0.01:1.0 is required to weigh the high purity Y 2 O 3 , Al 2 O 3 , CeO 2 , Sm 2 O 3 And Ga 2 O 3 , Get (Y 2.98 Ce 0.01 Sm 0.01 )(Al 4.0 Ga 1.0 )O 12 Ceramic material.

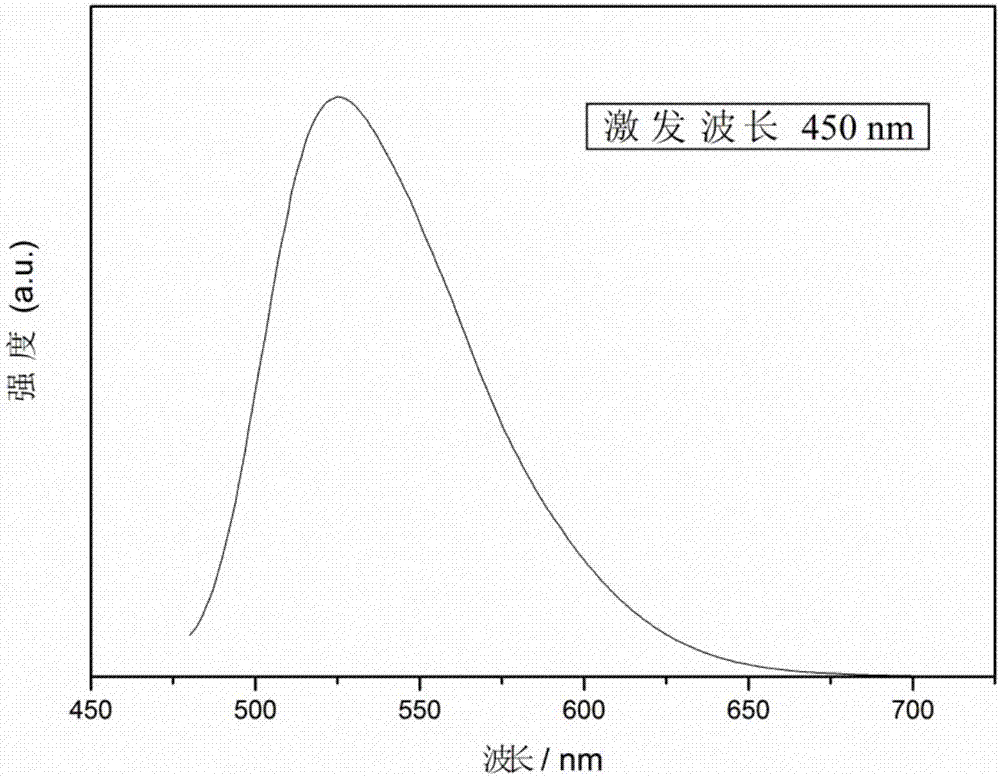

[0078] The ceramic material prepared in Example 2 of the present invention was tested according to the detection method of Example 1. The test result is that the ceramic material prepared in Example 2 of the present invention has a transmittance of 75% through wavelengths above 500 nm and is transparent. Ceramic, the thermal conductivity is 8.7W / m·K, the luminous intensities at 25℃, 50℃, 100℃, 150℃ and 200℃ are 1, 0.99, 0.956, 0.932, 0.907, and the thermal stability is good. It can emit green light with a peak position of 517nm under the excitation of, and the fluorescence conversion rate is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com