Preparation method of BOE (Buffered Oxide Etch)-resistant metal mask

A metal mask and mask technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of pattern line accuracy loss, low efficiency, sample contamination, etc., to improve sample structure accuracy, The effect of simplifying the process flow and reducing the coating stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

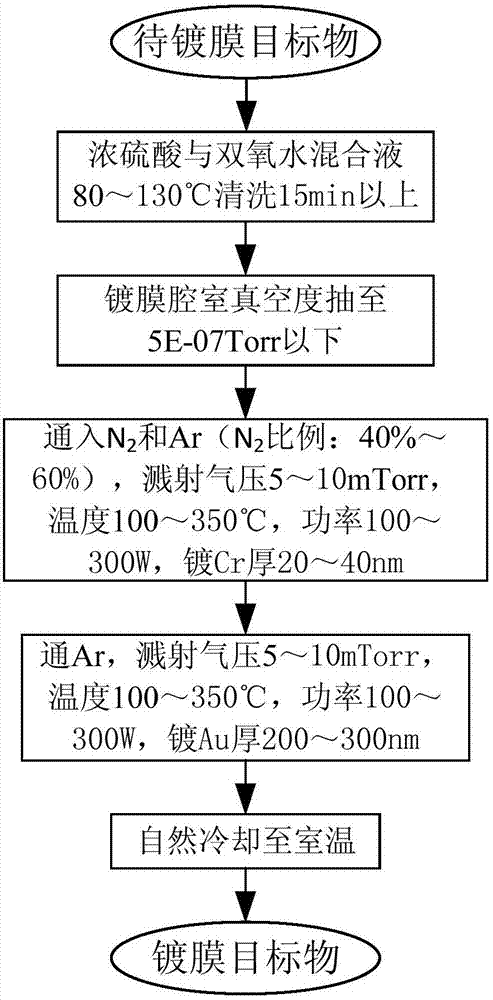

[0032] Such as figure 1 As shown, the present invention provides a method for preparing a metal mask resistant to BOE corrosion, and the steps are as follows:

[0033] Step a: cleaning the target to be coated;

[0034] Specifically: soak the target in a mixed cleaning solution of concentrated sulfuric acid and hydrogen peroxide. The temperature of the mixed cleaning solution is 80~130℃, and the immersion time is 15~30min. The mixing of concentrated sulfuric acid and hydrogen peroxide will produce a lot of bubbles (O 2 ) And release heat. The bubbles will take away the dust and particle attachments on the surface of the target. The concentrated sulfuric acid will corrode the organic pollutants. Heating will help to clean the target thoroughly.

[0035] Step b: Coating the target after cleaning;

[0036] The main innovation of the present invention is focused on the use of a single layer of Cr / Au mask during coating processing. Compared with the current technology multi-layer Cr / Au m...

Embodiment 1

[0044] Step a, cleaning: put the quartz crystal substrate into H 2 O 2 : Thick H 2 SO 4 =1:3 in the preparation of the cleaning solution, heat to 110°C, soak for 20-30min, take it out and wash with warm water.

[0045] Step b, coating: ①Put the cleaned and dried quartz crystal substrate into the sputtering coating machine and vacuumize to 3E-7 Torr; ②heat the quartz crystal substrate to about 320℃; ③flow Ar and N 2 , Change N 2 A total of 5 sets of comparative tests of A, B, C, D, and E are performed on the proportion of the volume, and the N of A, B, C, D, and E 2 The volume ratios are 20%, 40%, 50%, 60% and 80% respectively. Keep the pressure of the sputtering chamber at 5mTorr and the sputtering power at 150W to complete the 30nm-thick Cr film plating; ④Pour in Ar and keep sputtering The cavity pressure is 10mTorr, and the sputtering power is set to 200W to complete the 200nm thick Au film plating; ⑤ Naturally cool to room temperature and take out the coated quartz crystal subst...

Embodiment 2

[0048] Step a, cleaning: put the quartz crystal substrate into H 2 O 2 : Thick H 2 SO 4 =1:5 in the cleaning solution, heat to 130℃, soak for 15-25min, take it out and wash with warm water.

[0049] Step b, coating: ①Put the cleaned and dried quartz crystal substrate into the sputtering coating machine, and vacuum to the set value 1E-7Torr; ②heat the quartz crystal substrate to about 240℃; ③flow Ar and N 2 , N 2 The volume ratio is 55%. Keep the sputtering chamber pressure at 10mTorr and the sputtering power at 150W to complete the 20nm thick Cr film plating; ④Push into Ar, keep the sputtering chamber pressure at 10mTorr, set the sputtering power to 200W, Finish 300nm thick Au film plating; ⑤ Naturally cool to room temperature, take out the coated quartz crystal substrate.

[0050] Place the obtained single-layer Cr / Au masked quartz crystal substrate in BOE (40% HF solution: 40% NH at a temperature of 40~60℃) 4 F solution=1:2) Soak in corrosive solution for 20 hours. Analyzing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com