Lithium battery nickel-cobalt lithium manganate ternary anode material and preparation method thereof

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the direction of battery electrodes, positive electrodes, electrical components, etc., can solve the problem that ternary positive electrode materials cannot guarantee high specific capacity and good cycle performance at the same time, so as to improve the first discharge Capacity and cycle performance, increased lithium ion transport channels, uniform particle size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

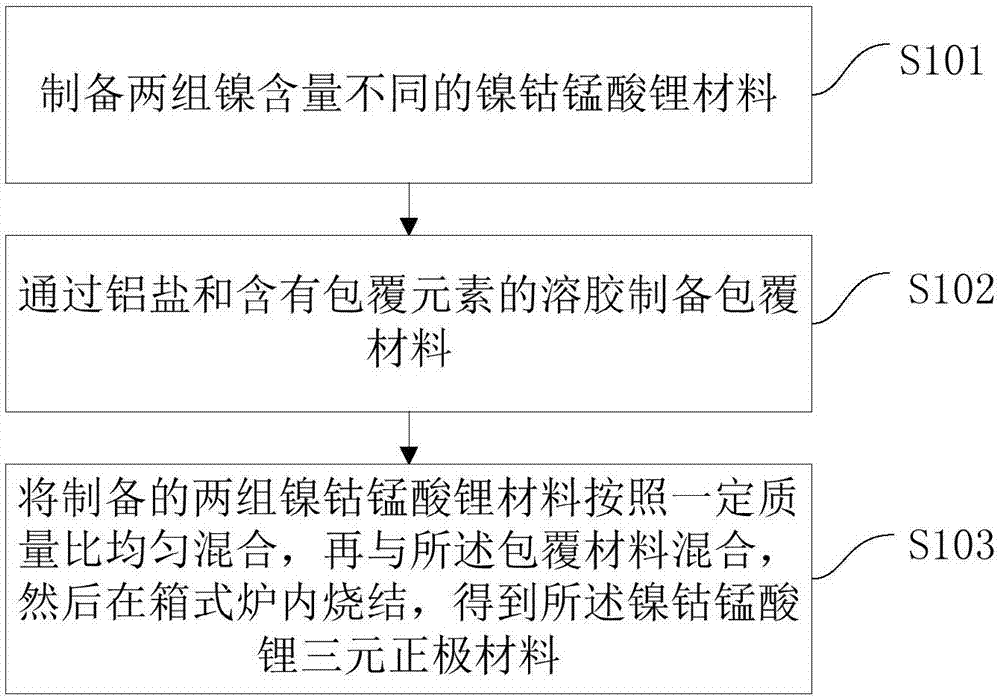

[0030] Such as figure 1 As shown, the preparation method of the lithium battery nickel cobalt manganese oxide lithium ternary positive electrode material provided herein comprises the following steps:

[0031] Step S101 , preparing two groups of nickel-cobalt-lithium-manganese oxide materials with different nickel contents.

[0032] In the process of preparing nickel-cobalt-manganese lithium manganate material, the ternary precursor containing nickel-cobalt-manganese and the lithium source are uniformly mixed according to the molar ratio of 1.00≤Li:(Ni+Co+Mn)≤1.10, that is, the lithium in the lithium source The molar ratio of the sum of nickel, cobalt and manganese elements in the nickel-cobalt-manganese ternary precursor is between 1.00 and 1.10. In this step, the lithium is lithium carbonate, lithium hydroxide and lithium oxalate. At least one of them; then sintering at a high temperature in the temperature range of 700-950° C. for 5-20 hours, and making the oxygen content ...

Embodiment 1

[0041] Select Ni:Co:Mn=50:20:30 and average particle size D 50 =10 μm nickel-cobalt-manganese ternary precursor, weigh an appropriate amount of lithium hydroxide according to the molar ratio Li:(Ni+Co+Mn)=1.03. The nickel-cobalt-manganese precursor and lithium hydroxide were mixed in a high-speed mixer for 3 hours, then placed in a box furnace at 900°C for sintering for 15 hours, and then the samples were taken out, pulverized and sieved to obtain nickel-cobalt lithium manganese oxide material A1. According to the above steps, the nickel-cobalt-manganese precursor with Ni:Co:Mn=55:25:20 and average particle size D50=10 μm was sintered at 900°C, crushed and sieved to obtain nickel-cobalt-lithium manganese oxide material A2. Then, the above two groups of nickel-cobalt-lithium-manganese-oxide materials were mixed for 1.5 hours according to the mass ratio A1:A2=1:1.

[0042] According to the molar ratio Al:Zr=1:2, the nanoscale Al 2 o 3 The powder was put into the zirconium sol...

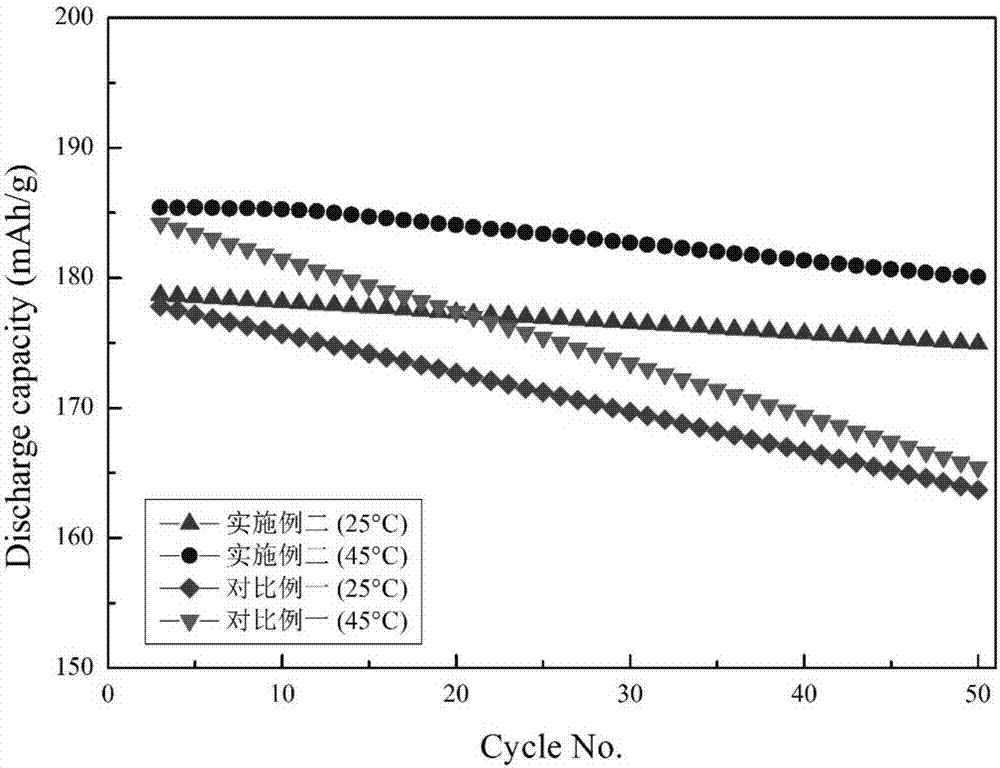

Embodiment 2

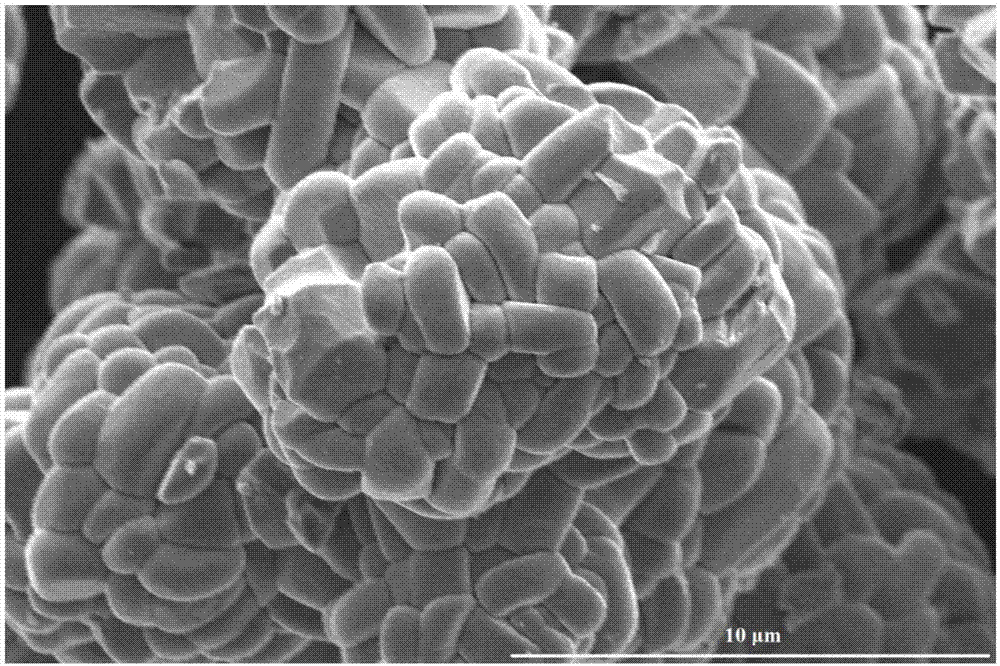

[0046] Select Ni:Co:Mn=60:20:20 and average particle size D 50 =15 μm nickel-cobalt-manganese ternary precursor, weigh an appropriate amount of lithium hydroxide according to the molar ratio Li:(Ni+Co+Mn)=1.07. The nickel-cobalt-manganese precursor and lithium hydroxide were mixed in a high-speed mixer for 3 hours, then placed in a box furnace at 850°C for sintering for 13 hours, and then the samples were taken out, pulverized and sieved to obtain nickel-cobalt lithium manganese oxide material A1. According to the above steps, Ni:Co:Mn=55:25:20 and average particle size D 50 =5 μm nickel-cobalt-manganese precursor was sintered at 900°C, crushed and sieved to obtain nickel-cobalt-lithium manganese oxide material A2. Then, the above two nickel-cobalt-lithium-manganese oxide products were mixed for 1.5 hours according to the mass ratio A1:A2=4:1.

[0047] According to the molar ratio Al:Ce=3:1, the nanoscale Al 2 o 3 Put it into the zirconium sol and stir for 1 hour, put it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com