Preparation method of modified alumina carrier

A technology of alumina support and modification, which is applied in the direction of catalyst support, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems such as the influence of support mechanical strength, and achieve the improvement of pore structure and mechanical strength. Strength, the effect of increasing the grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

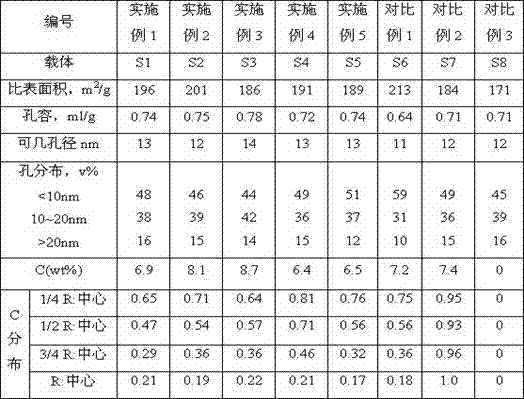

Embodiment 1

[0032]Weigh 10 grams of montmorillonite and bake at 950 °C for 5 hours. Mix the roasted montmorillonite with 200 g of pseudo-boehmite dry rubber powder (produced by Shandong Aluminum Co., Ltd.) and 6 grams of celadon powder, and pour into the mixture An appropriate amount of aqueous solution containing 5 grams of acetic acid was added to the material, extruded into a strip, dried at 120° C. for 5 hours, and then calcined at 300° C. for 5 hours. Put the roasted pseudo-boehmite in the polytetrafluoroethylene lining of the autoclave, add 400 grams of sodium hydroxide solution with a concentration of 4 mol / L at the same time, and heat the sealed autoclave at 90 ° C for 4 hours. The final material was filtered, washed with deionized water, dried at 110°C for 6 hours, and calcined at 600°C for 8 hours to obtain an alumina carrier.

[0033] Weigh 100 grams of the above-mentioned γ-phase cylindrical strip-shaped alumina carrier and put it into the spray rolling pot, and in the rotatin...

Embodiment 2

[0035] With embodiment 1, the add-on of diatomaceous earth is 30 grams. The low-temperature calcination temperature is 250° C., and the calcination time is 10 hours. The alkaline solution is a potassium hydroxide solution with a concentration of 3 mol / L, and the consumption of the solution is 1500 grams. The heat treatment temperature of the mixture was 100° C., and the treatment time was 3 hours. The alumina carrier is in the shape of clover strips. For the first spray and impregnation, use 30ml of an aqueous solution of sorbitol with a mass concentration of 30%, and for the second spray and impregnation, use 50ml of an aqueous solution of sorbitol with a mass concentration of 10%. In the first spraying and impregnation, 20ml of sorbitol aqueous solution with a mass concentration of 5% was used. The carbonization temperature was 200°C and the carbonization time was 8 hours to obtain carbon-containing alumina carrier S2. The properties of the carrier are shown in Table 1.

Embodiment 3

[0037] The montmorillonite was changed into kaolin the same as in Example 1, the roasting temperature was 1000° C., and the addition of kaolin was 20 grams. The low-temperature calcination temperature is 350° C., and the calcination time is 7 hours. The alkali solution is that the concentration is 5mol / L, and the solution consumption is 1200 grams. The heat treatment temperature of the mixture was 70° C., and the treatment time was 4 hours. Adopt four times of spray impregnation, use 20ml mass concentration to be the aqueous solution of mannitol of 50% when spraying and impregnating for the first time, use 40ml mass concentration to be the aqueous solution of sorbitol of 30% when spraying and impregnating for the second time, the third time Use 20ml of an aqueous solution of sorbitol with a mass concentration of 20% for spray impregnation, and use 20ml of an aqueous solution of sorbitol with a mass concentration of 10% for the fourth spray and impregnation. During the carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com