Three-dimensional metal nanowire and preparation method thereof

A metal nanowire and three-dimensional technology, applied in the field of nanomaterials, can solve the problems of highly ordered pore distribution, low space utilization, and failure to obtain a large-scale nanoporous structure, so as to improve cycle stability , Alleviate structural collapse and increase specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

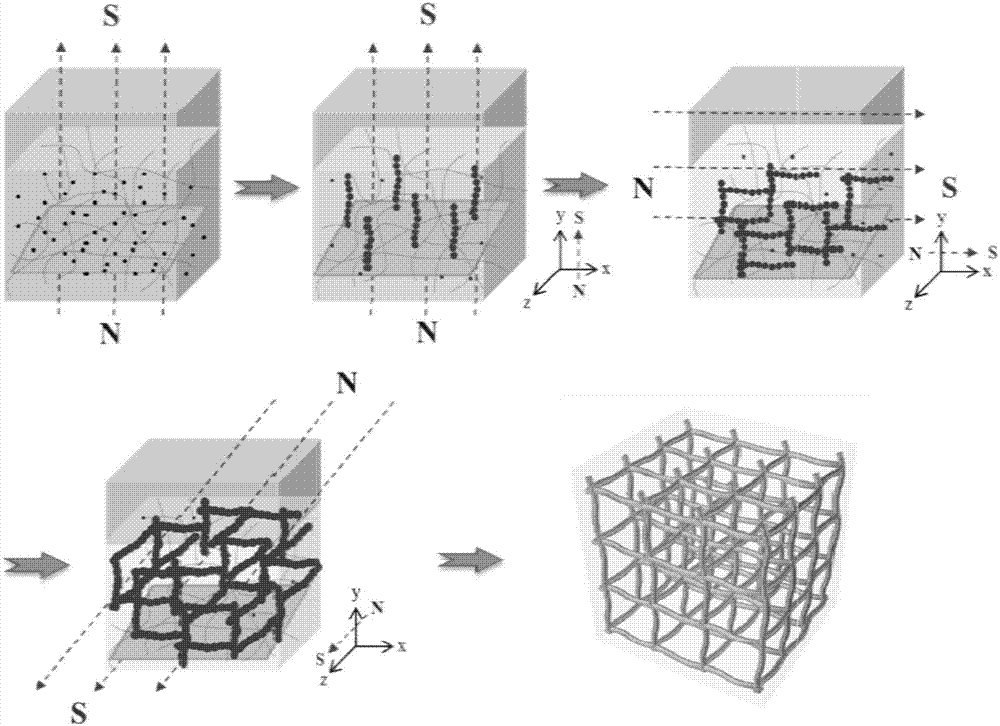

[0014] A method for preparing metal nanowires is provided in this specific embodiment, comprising the following steps:

[0015] S1, prepare a metal ion solution with a concentration of 0.01-1mol / L, add complexing agent and nucleating agent, and adjust the pH value to 10.0-13.5 with an alkali solution to prepare a solution A. Wherein, the metal ions are magnetic metal ions or a mixture of magnetic metal ions and non-magnetic metal ions.

[0016] In this step, the metal ion solution is preferably a metal salt solution. Wherein, the magnetic metal ions may be one or a mixture of divalent metal ions of nickel, cobalt and iron. The concentration of metal ions is 0.01-1 mol / L. On the one hand, if the concentration is too low, few metal nanowires can be obtained and the yield is low, which is not conducive to application. However, if the concentration is higher than 1mol / L, a large number of metal nanowires will be produced during the reduction process in the subsequent step S3. If...

Embodiment 1

[0039] (1) Preparation of metal ion solution (A solution):

[0040] Use water as a solvent to prepare 400mL of solution A at the following concentration, and use alkaline solution to adjust the pH of the solution to 12.0:

[0041] NiCl 2 0.1mol / L

[0042] Na 2 C 2 o 4 0.035mol / L

[0043] h 2 PdCl 4 0.2×10 -3 mol / L

[0044] (2) Configure strong reducing agent solution (B solution):

[0045] Prepare 400 mL of hydrazine hydrate solution with a concentration of 0.25 mol / L, and adjust the pH value to 12.5 with alkaline solution.

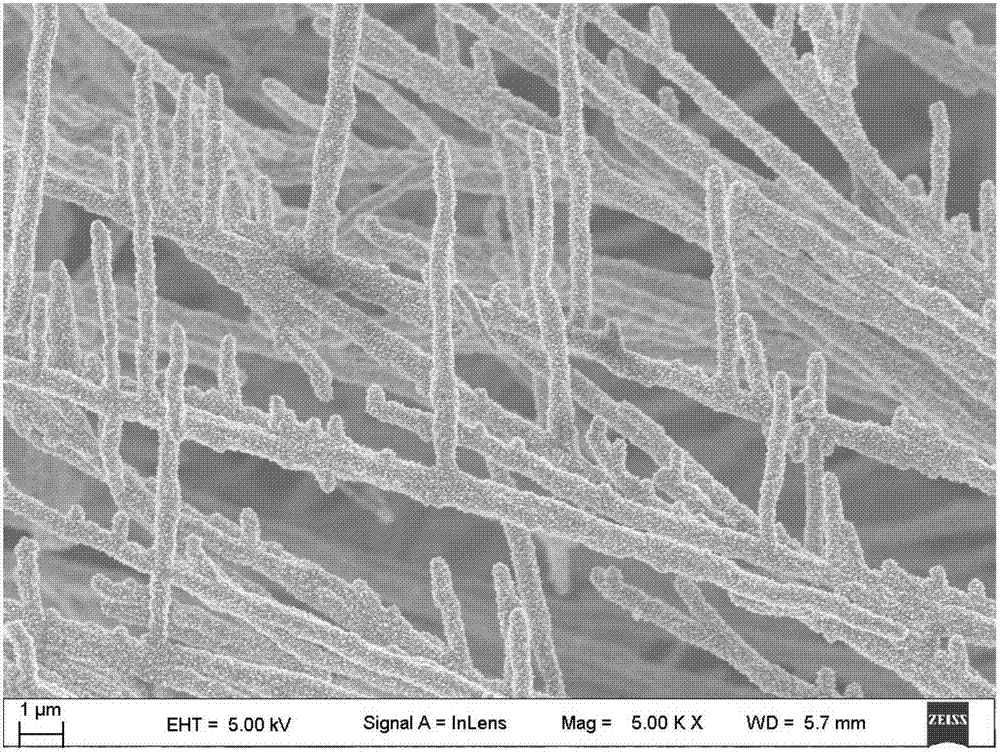

[0046] (3) Reduction in solution phase:

[0047]Preheat solution A and solution B in a water bath at 60°C for 30 minutes, and then mix them thoroughly. Place the titanium sheet magnetron sputtered with Pd in a reaction vessel, and pour it into a polyacrylamide solution at 60°C. The A solution and the B solution were placed in a reaction container and mixed thoroughly, and reacted for 15 minutes at 60 ° C and 0.1 T under the first magnetic...

Embodiment 2

[0050] (1) Preparation of metal ion solution (A solution):

[0051] Use water as a solvent to prepare 400mL of solution A at the following concentration, and use alkaline solution to adjust the pH of the solution to 12.0:

[0052]

[0053] (2) Configure strong reducing agent solution (B solution):

[0054] Prepare 400 mL of hydrazine hydrate solution with a concentration of 0.2 mol / L, and adjust the pH value to 12.0 with alkaline solution.

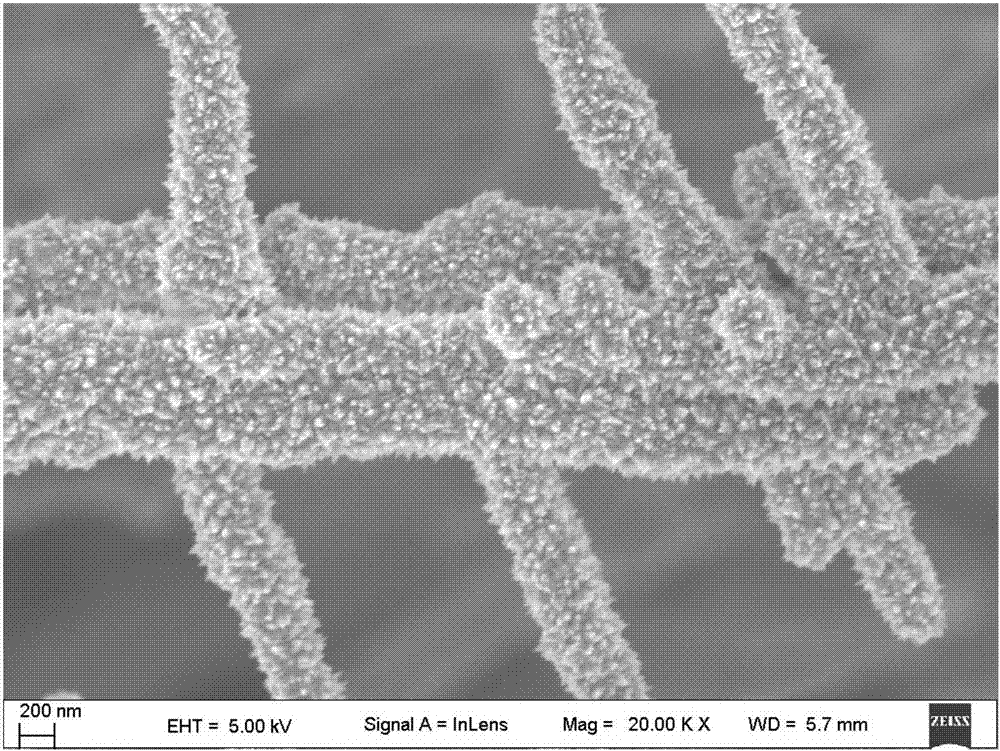

[0055] (3) Reduction in solution phase:

[0056] Preheat solution A and solution B in a water bath at 50°C for 30 minutes, then mix thoroughly, place the nickel sheet of electrodeposited platinum metal in the reaction vessel, and pour it into the acrylamide-sodium acrylate copolymer solution at 50°C , put the A solution and the B solution in a reaction container and mix them well, and react for 20 minutes at 50°C and a first magnetic field direction parallel to the direction of gravity at 0.08T, and then set the direction of the magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com