Method for producing cello-oligosaccharide

A technology of cello-oligosaccharide and a manufacturing method, which is applied in the direction of fermentation, etc., can solve the problems of time-consuming, difficulty in maintaining constant and stable discharge of extrusion die pressure, and expensive equipment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

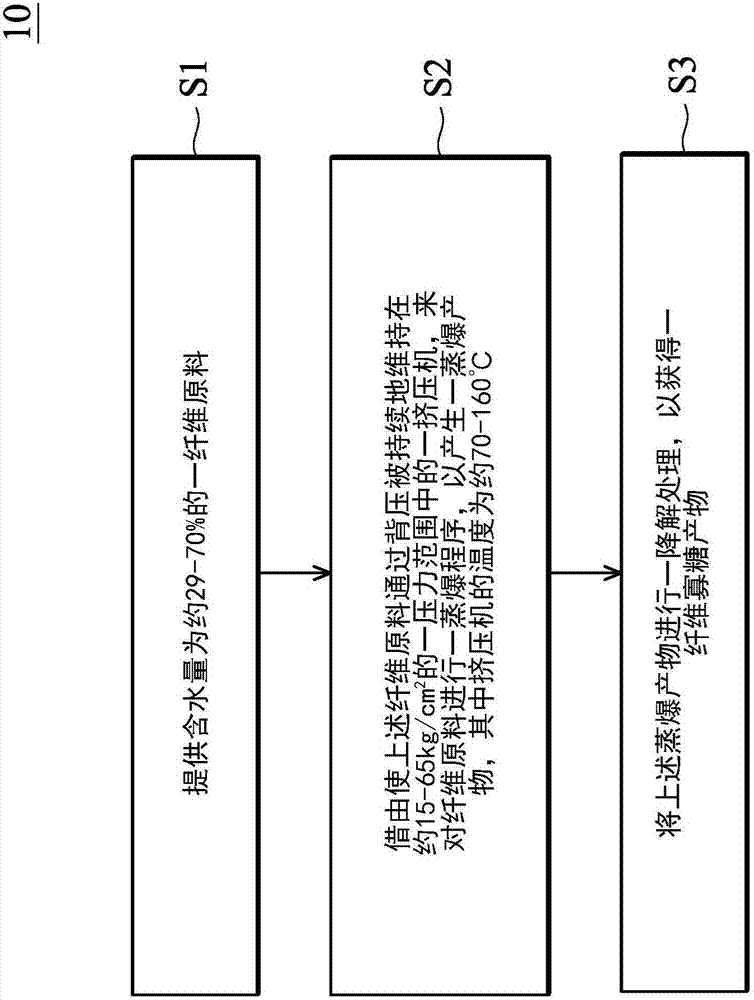

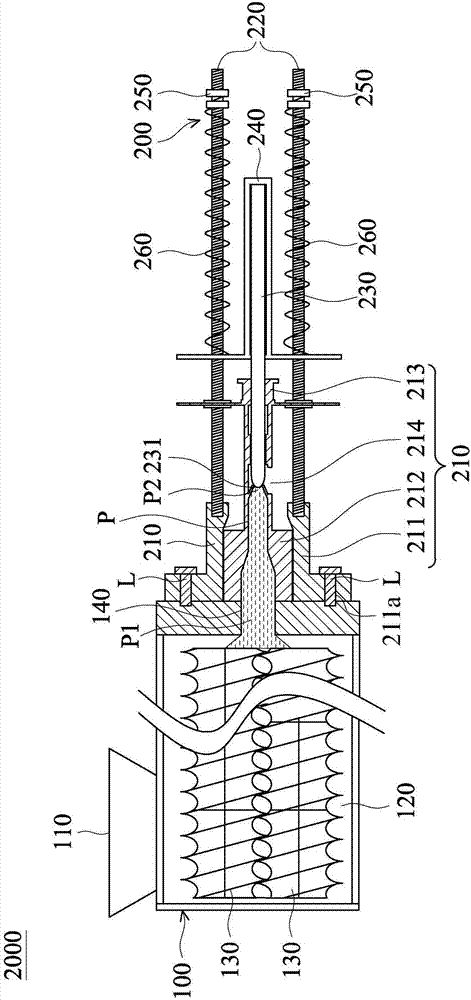

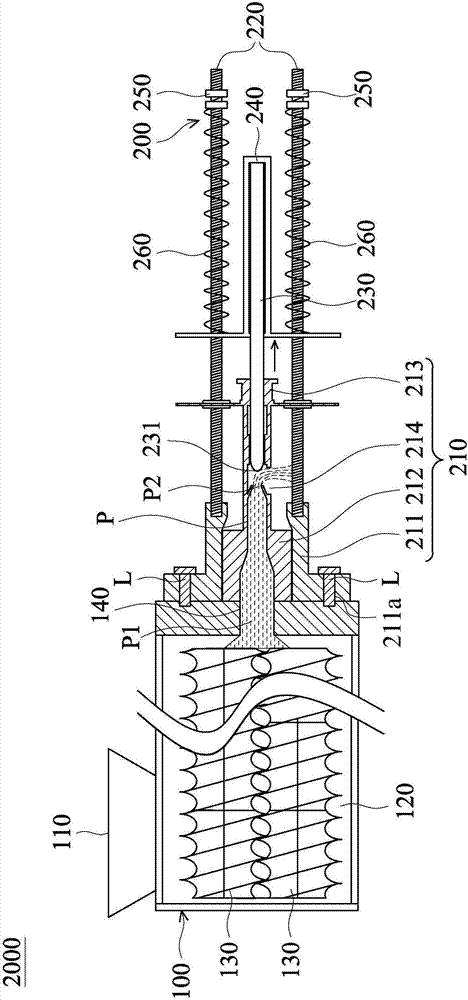

Method used

Image

Examples

Embodiment 1

[0074] The Effect of Steam Explosion Temperature on the Yield of Cellooligosaccharides

[0075] A. Experimental method

[0076] 1. Crush the wheat bran until it passes through an 80MESH sieve.

[0077] 2. After crushing, treat with amylase to remove starch.

[0078] 3. Put the starch-removed wheat bran into the extruder feeder.

[0079] 4. Carry out continuous extrusion steaming and explosion procedure:

[0080] The fixed parameters are feeding and water feeding at the same time, including 50% wheat bran and 50% moisture; the total production capacity is 30 kg per hour; the spindle speed of the extruder is 100 rpm; the back pressure of the extruder is controlled at 28-33 kg / cm 2 . Then carry out the continuous extrusion steam explosion of the following different temperature combinations respectively, to obtain steam explosion products of different temperatures:

[0081] (a) The first group of temperature combinations is set at 80, 110, 110, 110, and 110°C from the first t...

Embodiment 2

[0096] A. method

[0097] test 1

[0098] Effects of different back pressure ranges and production capacity of 40 kg per hour on cellooligosaccharides:

[0099] 1. Crush the wheat bran until it passes through an 80MESH sieve.

[0100] 2. After crushing, sieve the wheat bran with 100 MESH to remove the starch.

[0101] 3. Put the starch-removed wheat bran into the extruder feeder.

[0102] 4. The fixed temperature combination is set at 80, 95, 150, 150, 150°C from the first to the fifth sleeve.

[0103] 5. Carry out continuous extrusion steaming and explosion procedure:

[0104] The fixed parameters are feeding and water feeding at the same time, including 50% wheat bran and 50% moisture; the total production capacity is 40 kg per hour; the spindle speed of the extruder is 100rpm. Carry out the following continuous extrusion steam-explosion in different back pressure ranges to obtain steam-explosion products in different back pressure ranges:

[0105] (a) The first group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com