Soybean sauce brewing method capable of avoiding preservative in soybean sauce production

A technology for preservatives and soy sauce, applied in food science and other directions, can solve the problems of sour and astringent flavor of soy sauce, sour and astringent flavor of crude oil, and alcohol-containing taste, etc., to improve natural antiseptic performance, low water activity, and simple process and economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

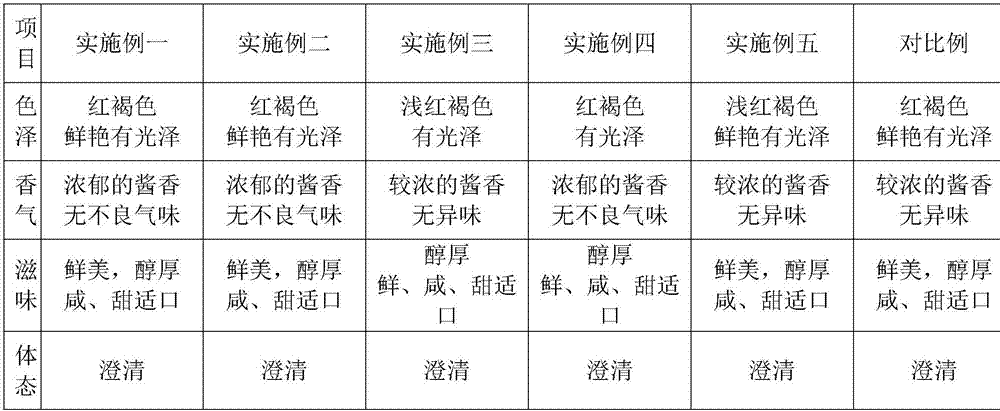

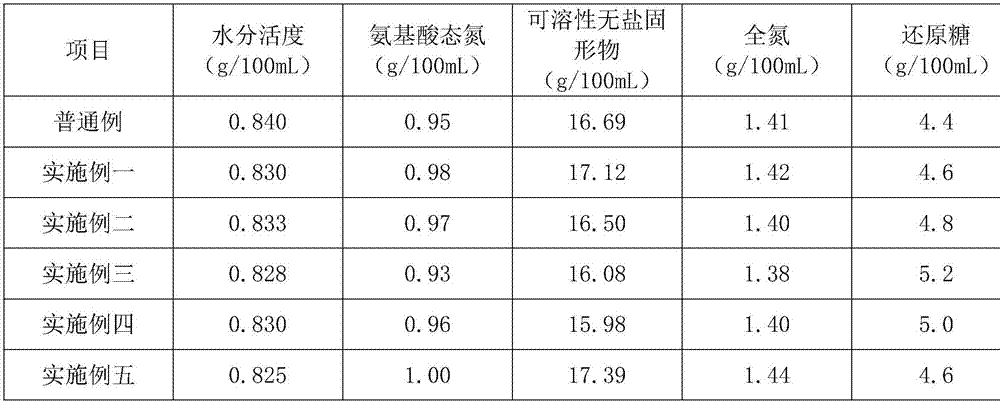

Examples

Embodiment 1

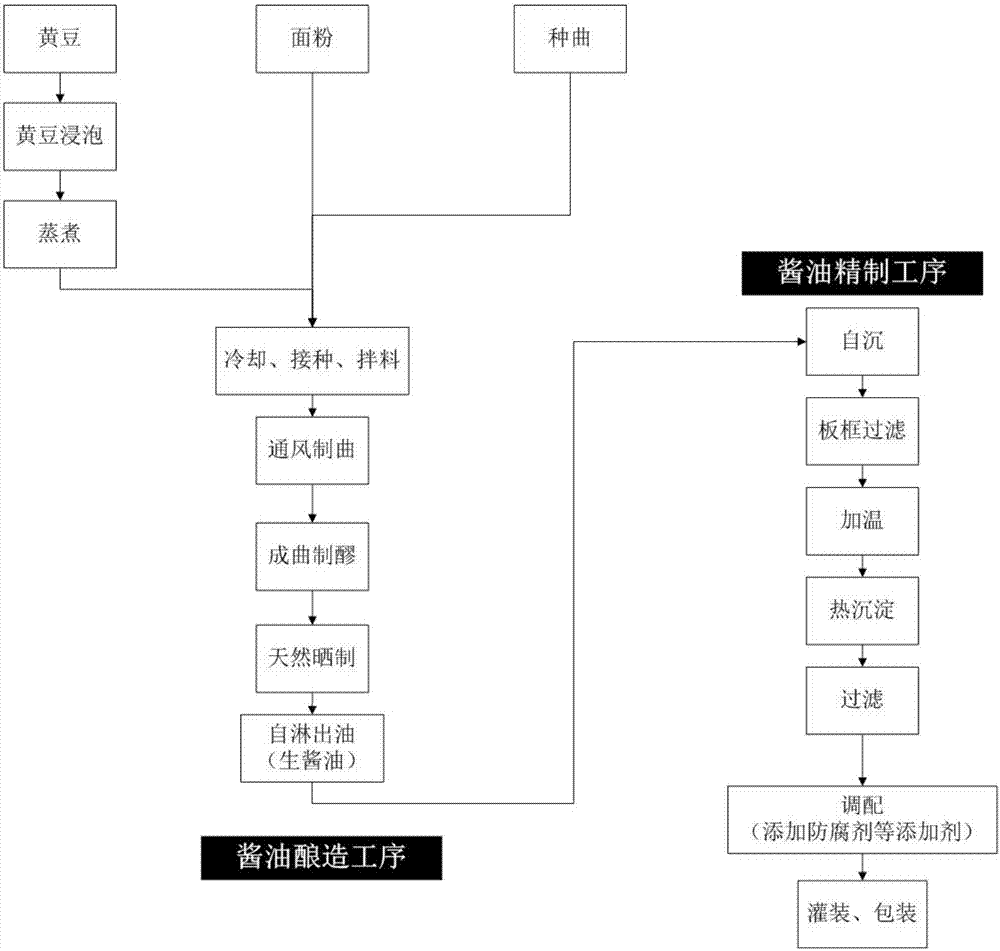

[0040] A kind of brewing process of soy sauce without preservatives, carries out according to the following steps:

[0041] 1) Cooking: steaming the soaked soybeans at a pressure of 0.12 MPa and a holding time of 5 minutes to obtain cooked beans.

[0042] 2) mixing: cooked beans and flour mixture are mixed according to the weight ratio of 1:0.1 to obtain the mixing;

[0043] 3) inoculation: when the temperature of the mixture was reduced to below 32° C., inoculate Aspergillus oryzae, and the inoculum size was 0.3% of the mixture gross weight;

[0044] 4) koji making: the mixed material after inoculation is sent into the ventilated fermenting tank of the fermentation room to cultivate for 48 hours, and the koji is loosened 1 time every 15 hours; 35°C; in the later stage of cultivation, that is, after 20 hours of cultivation, control the temperature of Daqu at 27°C until the koji is formed;

[0045] 5) Fermentation: The koji and salt water are mixed according to the weight rat...

Embodiment 2

[0048] A kind of brewing process of soy sauce without preservatives, carries out according to the following steps:

[0049] 1) Cooking: steaming the soaked soybeans under the conditions of pressure 0.1MPa and pressure holding time 10min to obtain cooked beans.

[0050] 2) mixing: cooked beans and flour mixture are mixed according to the weight ratio of 1:0.2 to obtain the mixing;

[0051] 3) inoculation: when the temperature of the mixture was down to below 28 DEG C, the aspergillus oryzae was inoculated, and the inoculum size was 0.7% of the mixture gross weight;

[0052] 4) koji making: the mixed material after inoculation is sent into the ventilated fermenting pool of the fermentation room to cultivate for 36 hours, and the koji is loosened 1 time every 15 hours; in the early stage of cultivation, that is, in the 0 hour to the 20th hour, the temperature of the koji is controlled at 28°C; in the later stage of cultivation, that is, after 20 hours of cultivation, control the...

Embodiment 3

[0056] A kind of brewing process of soy sauce without preservatives, carries out according to the following steps:

[0057] 1) Cooking: steaming the soaked soybeans under the conditions of pressure 0.1MPa and pressure holding time 15min to obtain cooked beans.

[0058] 2) mixing: cooked beans and flour mixture are mixed according to the weight ratio of 1:0.15 to obtain the mixing;

[0059] 3) inoculation: when the temperature of the mixture was down to below 35°C, the aspergillus oryzae was inoculated, and the inoculum size was 0.4% of the mixture gross weight;

[0060] 4) koji making: the mixed material after inoculation is sent into the ventilated fermenting tank of the fermentation room to cultivate for 40 hours, and the koji is loosened 1 time every 15 hours; in the early stage of cultivation, that is, in the 0 hour to the 20th hour, the temperature of the koji is controlled at 30°C; in the later stage of cultivation, that is, after 20 hours of cultivation, control the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com