Device for increasing reuse rate of purified water of refinery plant, and using method of device

A technology for water purification and refinery, applied in chemical instruments and methods, separation methods, filtration circuits, etc., can solve problems such as risks, large investment in equipment, increase industrial water consumption, etc., to achieve easy popularization, low investment cost, and Low maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

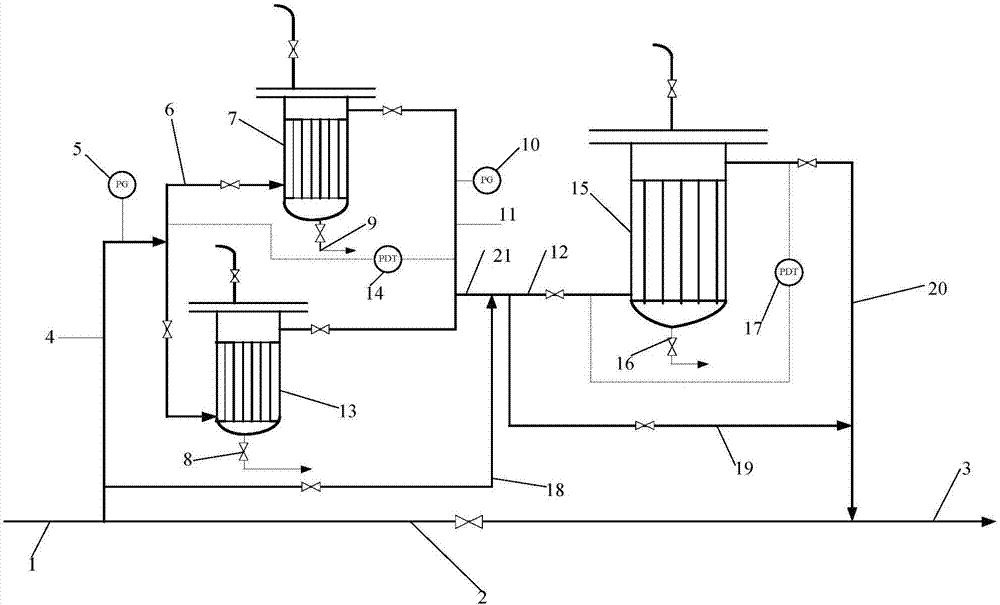

[0038] Such as figure 1 The untreated purified water enters through the purified water main pipeline 1, passes through the inlet pipeline 4 of the primary filter, and enters the filter one 7 for filtration. The first stage filter 15 carries out secondary filtration, and after the treatment, the water is purified and the water injection line enters the water injection raw material tank as the water injection source. The primary and secondary filter cross-lines are used for the simultaneous maintenance of the primary and secondary filters, and the purified water is not interrupted and used for a short time. One of the primary filters is equipped with two filters. Normally, one is used and the other is for standby. When the differential pressure gauge 14 shows that the predetermined differential pressure value is reached, switch to the spare filter 17. The removed filter is purified after passing through the primary filter. The water is discharged from the outlet branch line 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com