Conductive ink low-temperature curing composition and preparing method thereof

A conductive ink and composition technology, which is applied in the field of conductive ink low-temperature curing composition and its preparation, can solve the problems of complex process and high cost, and achieve the effects of simple operation, low cost and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

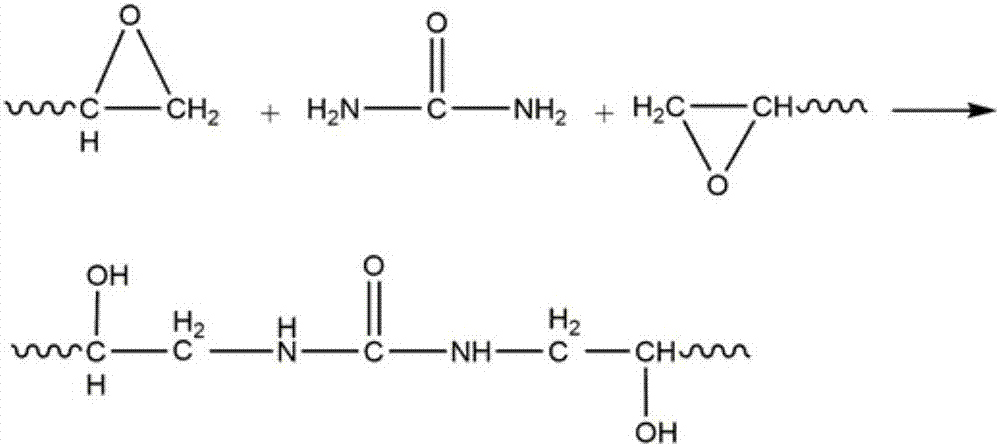

Method used

Image

Examples

Embodiment 1

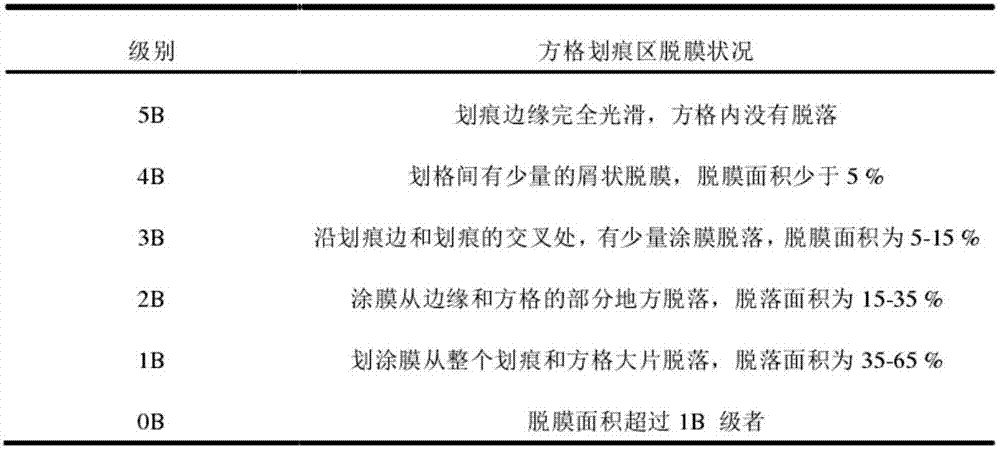

[0035] Weigh 4 parts of epoxy resin, 1 part of urea, 2 parts of ethylene glycol ether acetate, 1 part of terpineol, 1 part of additives, and 2 parts of graphene, and add them to a mixer and stir for 4 hours. Use a coating bar to coat on a smooth polyester film with a thickness of 0.2mm, and dry it in an oven at 100°C for 15 minutes to obtain a solid transparent resin film, and then measure it with tape according to the American Society for Testing and Materials standard ASTMD3359-74 Standard Method for Coating Film Adhesion "Test the adhesion of the sample, fix the sample, draw 11 horizontal and vertical lines with a cross-cutting knife, the line spacing is 1mm, and draw 100 small grids of 1mm x 1mm. Then use 3M#600 adhesive tape to cover the entire grid, and rub the rubber head on the cover, so that the color under the transparent tape is consistent and the adhesion is good. After sticking the tape and keeping it for 90±30s, pull off the tape quickly (not suddenly) in the opp...

Embodiment 2

[0039] Weigh 2 parts of epoxy resin and 3 parts of terpineol and mix evenly, then add 1 part of urea to the mixer. After it is completely dissolved, add 3 parts of conductive carbon black and 1 part of ethyl cellulose that pass through a 400 mesh screen, and stir evenly. A 300-mesh screen printing screen was selected, and the evenly stirred slurry to be tested was printed on a polyester film with a thickness of 0.1 mm. Dry in an oven at 120°C for 20 minutes. Bend the screen-printed pattern 180° outward according to the center line, then press it with a 2kg weight, keep it for 1min, and then open the diaphragm to flatten it. After repeated bending for 10 times in this way, the diaphragm was flattened, and the pattern did not fall off.

Embodiment 3

[0041] Weigh 2.5 parts of epoxy resin, 0.5 parts of urea, 2 parts of terpineol, 1 part of butyl acetate, 2 parts of graphite powder, 1 part of conductive carbon black, and 1 part of ethyl cellulose, and add them to a ball mill jar for ball milling for 6 hours. A 300-mesh screen printing screen was selected, and the evenly stirred slurry to be tested was printed on a polyester film with a thickness of 0.1 mm. Dry in an oven at 80°C for 30 minutes. Bend the screen-printed pattern 180° outward according to the center line, then press it with a 2kg weight, keep it for 1min, and then open the diaphragm to flatten it. After repeated bending for 10 times in this way, the diaphragm was flattened, and the pattern did not fall off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com