Anti-swelling stabilizer for fracturing

A stabilizer and anti-swelling technology, which is applied in the field of preparation of chemical products in oil and gas fields, can solve the problems of ineffective clay migration prevention, poor temperature resistance and anti-swelling performance, and inability to produce multi-point adsorption, and achieves enhanced binding force and high efficiency. Anti-swelling performance, the effect of preventing hydration and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

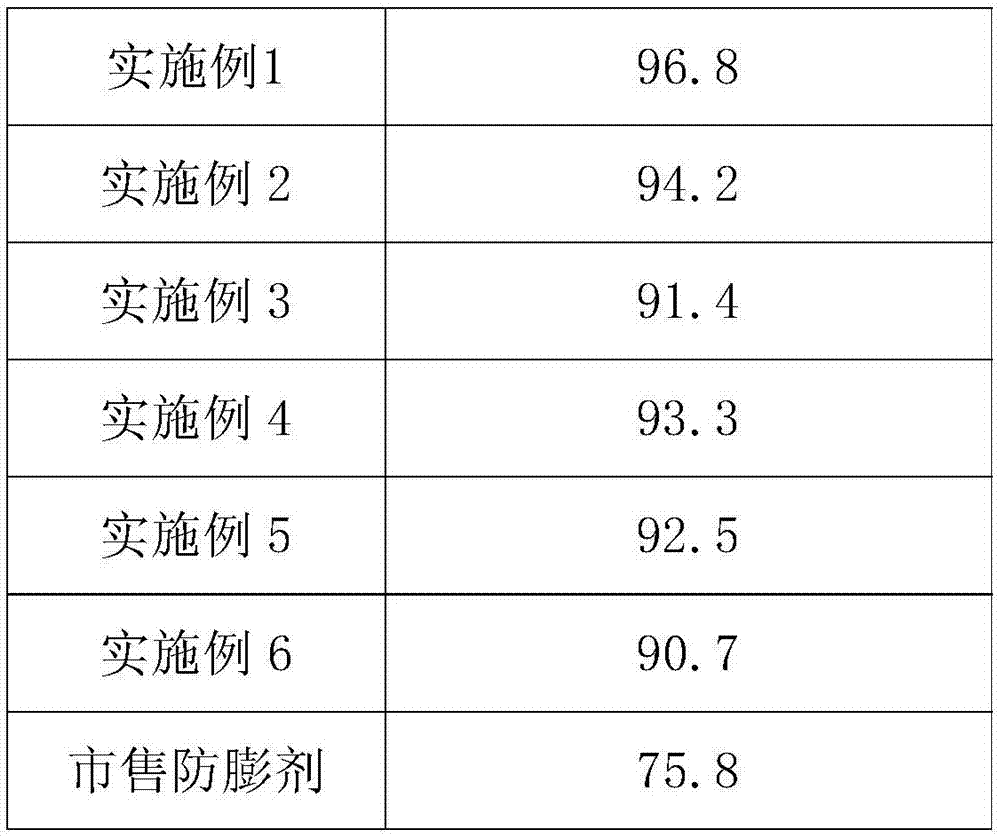

Examples

Embodiment 1

[0013] An anti-swelling stabilizer for fracturing, comprising the following components by mass percentage: 25% polydimethyldiallyl ammonium chloride, 10% sodium chloride, and 5% alkylphenol polyoxyethylene ether and water 60%.

[0014] The preparation process of the anti-swelling stabilizer for above-mentioned fracturing is specifically as follows: after adding 60 g of water, 25 g of polydimethyldiallyl ammonium chloride, and 5 g of alkylphenol polyoxyethylene ether into a stirred reactor, Raise the temperature to 70°C for 1 hour, then cool to room temperature, then add 10 g of sodium chloride, stir for 1 hour to obtain an anti-swelling stabilizer.

Embodiment 2

[0016] An anti-swelling stabilizer for fracturing, comprising the following components by mass percentage: 28% polytrimethylallyl ammonium chloride, 15% potassium chloride, dodecyl dimethyl benzyl chloride Ammonium chloride 10% and water 47%.

[0017] The preparation process of the anti-swelling stabilizer for above-mentioned fracturing is specifically as follows: add 47g water, 28g polytrimethylallyl ammonium chloride, 10g dodecyldimethylbenzyl chloride into a reactor with stirring After mixing the ammonium, raise the temperature to 60°C for 2 hours, then cool to room temperature, add 15 g of potassium chloride, stir for 1.5 hours to obtain an anti-swelling stabilizer.

Embodiment 3

[0019] An anti-swelling stabilizer for fracturing, comprising the following components by mass percentage: 30% poly 2-hydroxypropyl-1,1-N-dimethylammonium chloride, 13% potassium chloride, alkane Base phenol ethoxylate 5% and water 52%.

[0020] The preparation method of the above-mentioned anti-swelling stabilizer for fracturing, the specific process is as follows: add 52g water, 30g poly 2-hydroxypropyl-1,1-N-dimethylammonium chloride, 5g After the alkylphenol polyoxyethylene ether was mixed, the temperature was raised to 50°C for 3 hours, then cooled to room temperature, and 13 g of potassium chloride was added, and the anti-swelling stabilizer was obtained after stirring for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com