Mobile laboratory for biological repair of oily sludge

A mobile laboratory and bioremediation technology, applied in specific-purpose bioreactors/fermenters, biomass post-processing, biomass pretreatment, etc. problems, to reduce the possibility of damage or contamination, improve accuracy and work efficiency, and achieve the effect of complete auxiliary functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

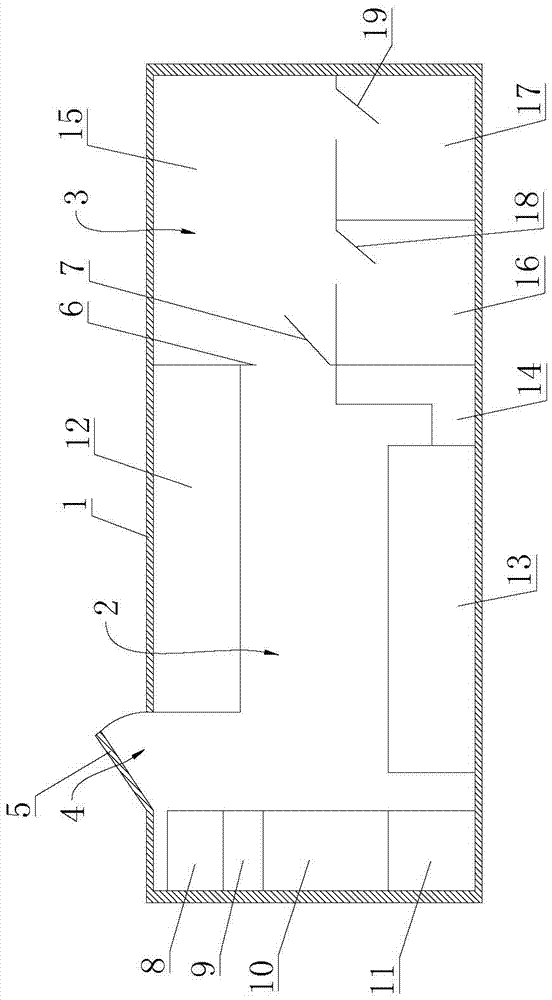

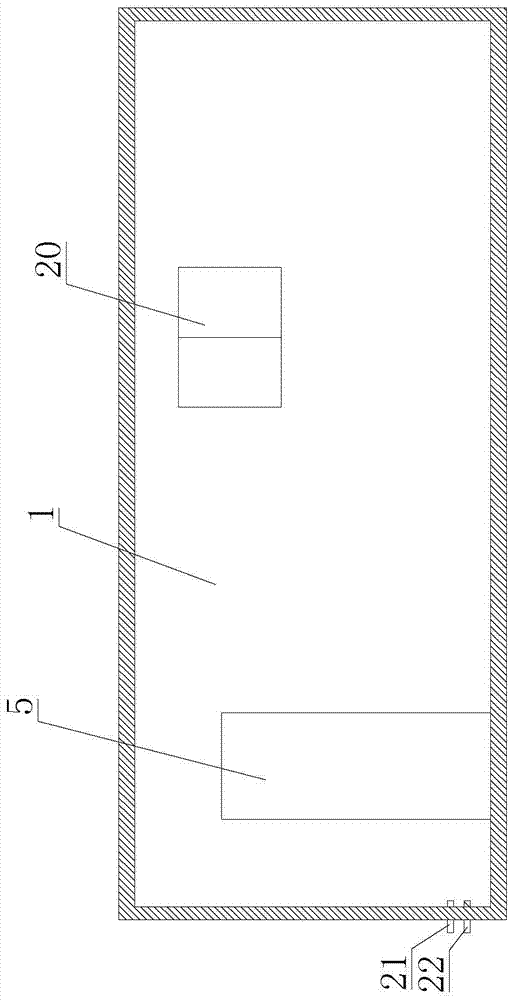

[0020] See figure 1 , figure 2 , a mobile laboratory for oily sludge bioremediation of the present invention, comprising a container box 1, the container box 1 is a vehicle-mounted container, the container box 1 can be installed on a car to realize the movement of the container box, the container box The body 1 is provided with an insulation layer, and the insulation layer is a polyurethane layer. An auxiliary physical and chemical analysis functional area 2 and a microbiological functional area 3 are provided in the container box, and a laboratory entrance 4 on one side wall of the auxiliary physical and chemical analysis functional area 2 is provided. The chamber entrance 4 is provided with a hermetic door 5 hinged on the container body 1. Close the airtight door 5 to form a closed space inside the container body 1. The auxiliary physical and chemical analysis functional area 2 and the microbial functional area 3 are separated by a partition 6. A first communication door 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com