Alkali soluble photosensitive compound, preparation method and application thereof

A photosensitive composition and photosensitive resin technology, which is applied in the field of photosensitive materials, can solve problems such as viscosity increase, alkali-soluble photosensitive composition system uncleanness, dry film cured product falling off, etc., and achieve the effect of improving reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

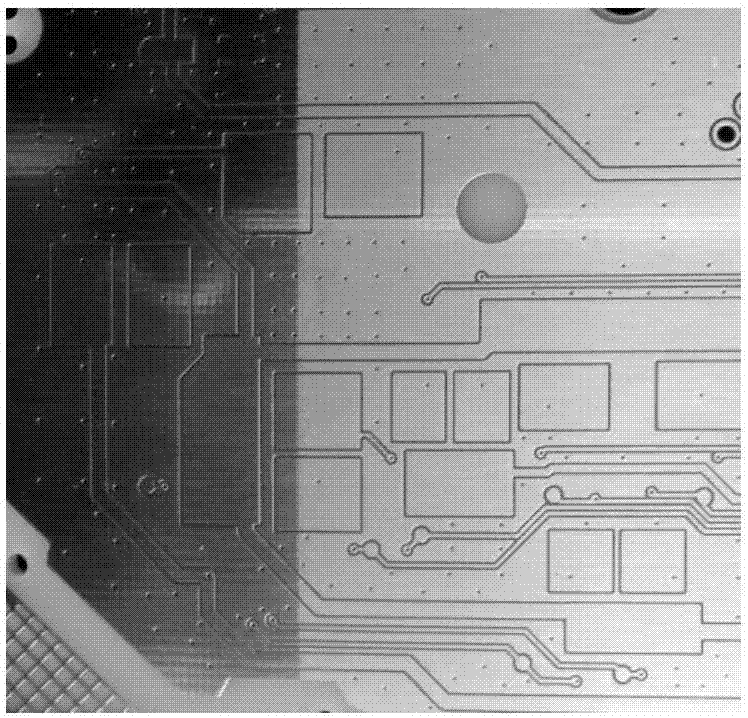

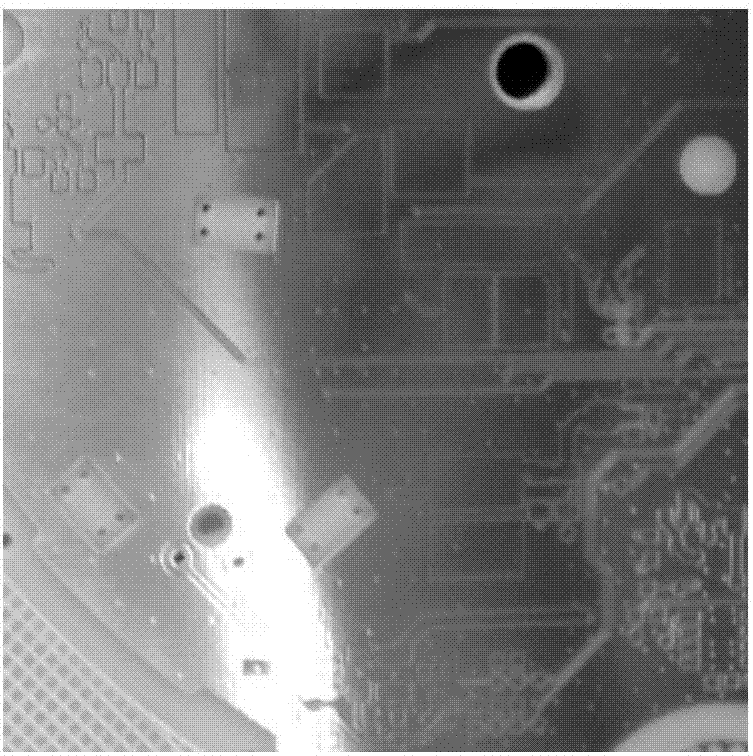

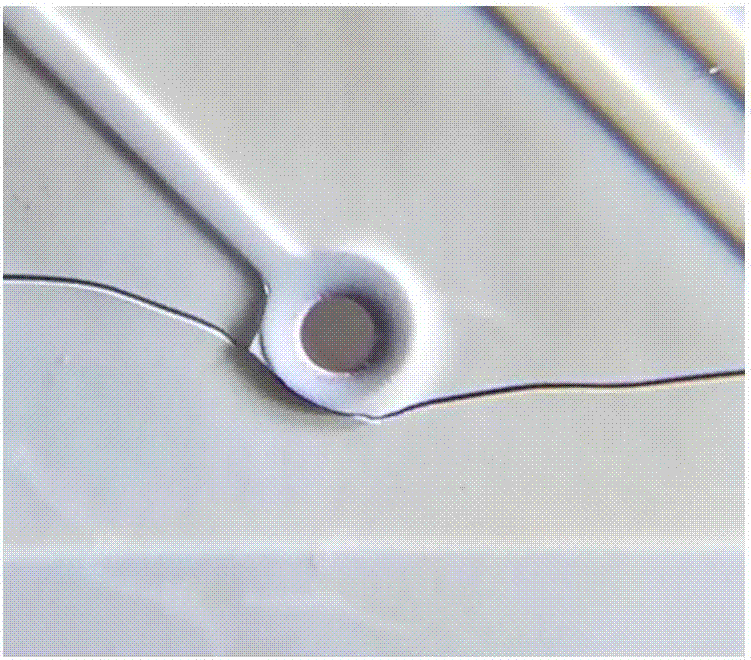

Image

Examples

Embodiment 1

[0047] A preparation method of an alkali-soluble photosensitive composition, the preparation method comprising the steps of:

[0048] (1) Preparation of component A main agent

[0049] ① First, 40 parts of alkali-soluble photosensitive resin (CCR-4959HW of Huayao Chemical Industry), 4 parts of photopolymerizable monomer (EM265 produced by Changxing Chemical), and 4 parts of diluent DCAC (produced by DOW Chemical in the United States) were mixed with a dispersing machine Stir and disperse for 10 minutes at a speed of 1500rpm;

[0050] ② Then add 4 parts of photoinitiator (3.6 parts of Irgacure 907 produced by Ciba, 0.4 parts of Irgacure ITX produced by Ciba), add while stirring, stir and disperse for 5 minutes at a speed of 1500rpm;

[0051] ③ Add 0.8 parts of amine catalyst (2E4MZ produced by Shikoku Chemicals, Japan), add while stirring, and stir and disperse at a speed of 1500rpm for 5 minutes;

[0052] ④Finally add 24 parts of titanium dioxide (DuPont R103) and 3.2 parts ...

Embodiment 2

[0058] A preparation method of an alkali-soluble photosensitive composition, the preparation method comprising the steps of:

[0059] 1) Preparation of component A main agent

[0060] ① First, 40 parts of alkali-soluble photosensitive resin (CCR-4959HW of Huayao Chemical Industry), 4 parts of photopolymerizable monomer (EM265 produced by Changxing Chemical), and 4 parts of diluent DCAC (produced by DOW Chemical in the United States) were mixed with a dispersing machine. Stir and disperse for 10 minutes at a speed of 1500rpm;

[0061] ② Then add 4 parts of photoinitiator (3.6 parts of Irgacure 907 produced by Ciba, 0.4 parts of Irgacure ITX produced by Ciba), add while stirring, stir and disperse for 5 minutes at a speed of 1500rpm;

[0062] ③ Add 0.8 parts of amine catalyst (2E4MZ produced by Shikoku Chemicals, Japan), add while stirring, and stir and disperse at a speed of 1500rpm for 5 minutes;

[0063] ④Finally add 24 parts of titanium dioxide (DuPont R103) and 3.2 parts ...

Embodiment 3

[0069] A preparation method of an alkali-soluble photosensitive composition, the preparation method comprising the steps of:

[0070] 1) Preparation of component A main agent

[0071] ① First, 40 parts of alkali-soluble photosensitive resin (CCR-4959HW of Huayao Chemical Industry), 4 parts of photopolymerizable monomer (EM265 produced by Changxing Chemical), and 4 parts of diluent DCAC (produced by DOW Chemical in the United States) were mixed with a dispersing machine. Stir and disperse for 10 minutes at a speed of 1500rpm;

[0072]② Then add 4 parts of photoinitiator (3.6 parts of Irgacure 907 produced by Ciba, 0.4 parts of Irgacure ITX produced by Ciba), add while stirring, stir and disperse for 5 minutes at a speed of 1500rpm;

[0073] ③ Add 0.8 parts of amine catalyst (2E4MZ produced by Shikoku Chemicals, Japan), add while stirring, and stir and disperse at a speed of 1500rpm for 5 minutes;

[0074] ④Finally add 24 parts of titanium dioxide (DuPont R103) and 3.2 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com