Method for direct filtration of municipal wastewater with plate ceramic membrane

A ceramic membrane and flat plate technology, applied in the field of environmental sewage treatment, can solve the problems of long recovery period, long initial start-up time, and difficulty in achieving stable water output, so as to reduce the concentration of organic matter and phosphorus, reduce the membrane fouling rate, and shorten the hydraulic pressure. The effect of dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

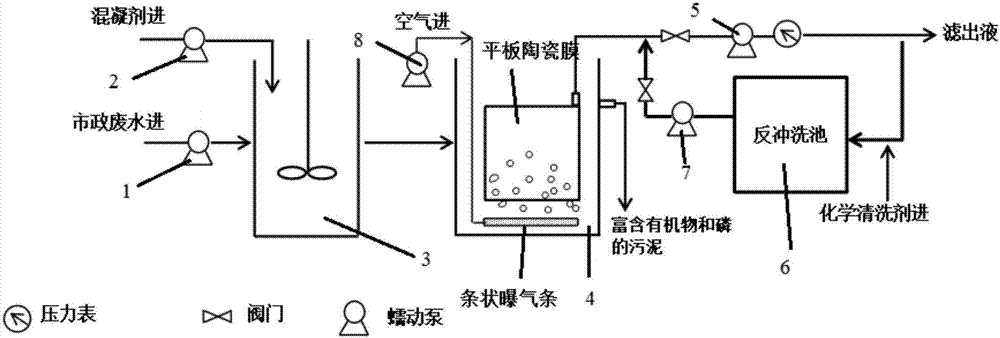

[0034] refer to figure 1, the present invention provides a kind of municipal waste water pretreatment system, it is characterized in that, it comprises inlet pump (1), feed pump (2), coagulation reaction tank (3), ceramic membrane reaction tank (4), suction pump (5), backwash tank (6) and backwash pump (7); Ceramic membrane reactor comprises intake pump (8); Inlet pump (1) is connected with the water inlet of coagulation reaction tank (3) by pipeline, enters The drug pump (2) is connected to the drug inlet of the coagulation reaction tank (3) through a pipeline, and the water outlet of the coagulation reaction tank (3) enters the ceramic membrane reaction tank (4) through the pipeline under the action of gravity, and the ceramic membrane reaction tank (4) An aeration strip is installed at the bottom, the aeration strip is connected with the intake pump (8), the water outlet of the ceramic membrane is connected with the water pump (5), and the outlet of the ceramic membrane rea...

Embodiment 2

[0036] refer to figure 1 , on the basis of Example 1, when the ceramic membrane needs to be cleaned after being polluted, chemical reagents are added to the backwash pool (6), and then the ceramic membrane is backwashed, and the outlet of the backwash pool (6) is connected to the backwash tank (6) through a pipeline. Rinse the pump (7), import the cleaning solution into the ceramic membrane reaction tank, and continue the filtration process with the cleaned ceramic membrane.

[0037] On the basis of Example 1, the polluted ceramic membrane can efficiently remove membrane fouling and restore the original state of the membrane through low-pressure on-line / off-line backwashing.

Embodiment 3

[0039] A kind of flat ceramic membrane using a kind of municipal wastewater pretreatment system of embodiment 2 directly filters the treatment method of municipal wastewater comprising:

[0040] (1) Municipal wastewater enters the first pool, and the coagulant ferric chloride or polyaluminium chloride is added under the action of quick stirring. After adding the coagulant, the coagulant suspension flows into the second pool. In this way, the coagulation process can be realized, and the destabilization and settlement of suspended particles and organic pollutants can be promoted.

[0041] (2) The coagulation suspension flows into the second tank, and the coagulation suspension is filtered through a flat ceramic membrane to obtain purified water, wherein the second tank is provided with a flat ceramic membrane and a gas inlet, and the gas inlet is on the flat plate The bottom of the ceramic membrane reaction tank is aerated with a strip-shaped aeration strip, and the aeration str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com