Laser spiral machining, grinding and drilling compound device and drilling method

A compound device and helical milling technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve the problems of hole wall burns, holes prone to taper holes, fiber faults, etc., to reduce costs, improve hole making accuracy, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

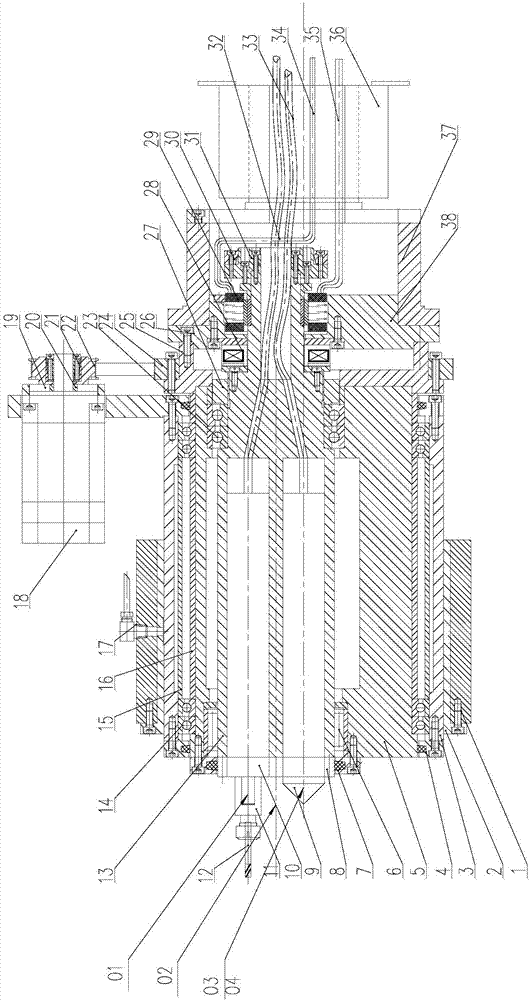

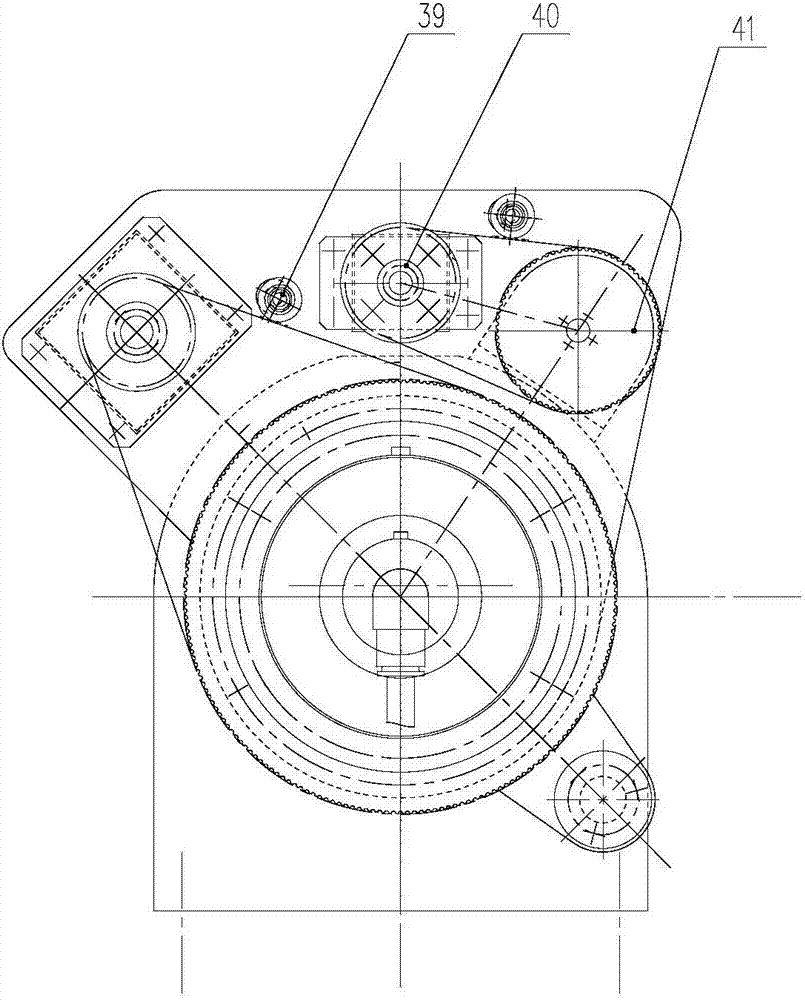

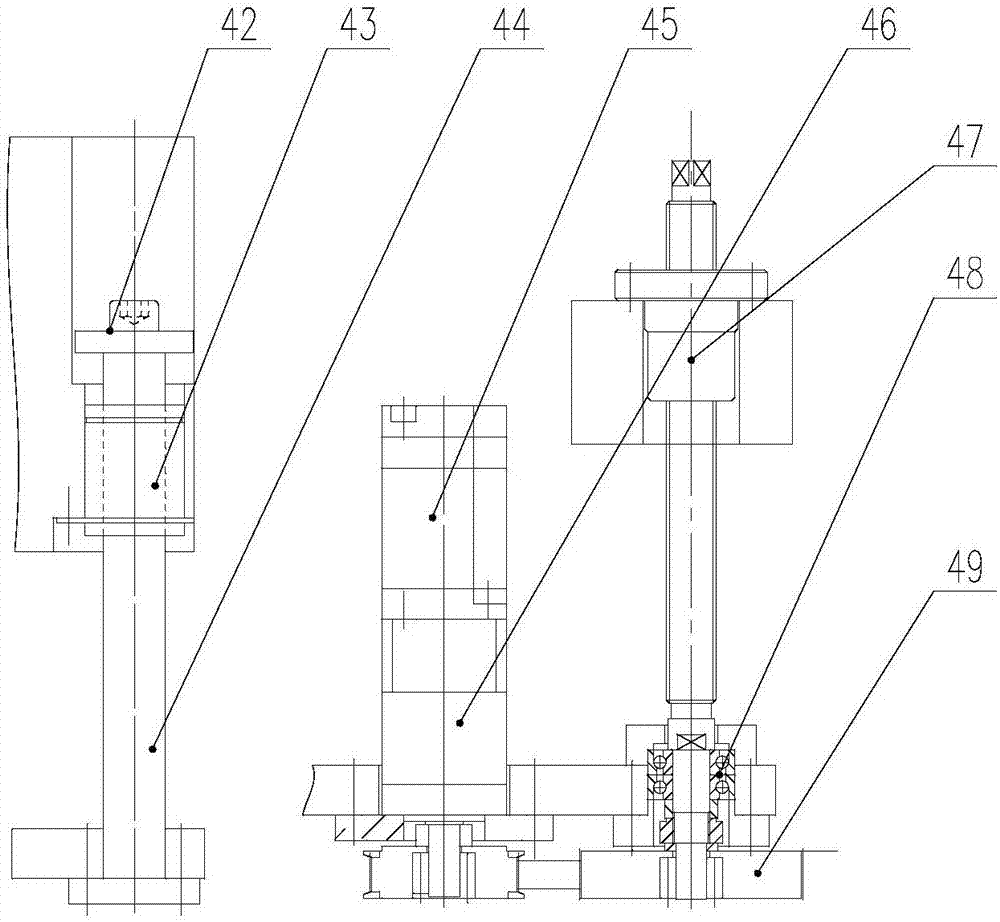

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] see Figure 1-4 According to the present invention, the laser spiral milling and hole-making compound device includes a laser generator 9 and a high-speed electric spindle 10 respectively installed in the two eccentric holes of the adjustment shaft 13 . The adjustment shaft 13 is supported and installed in the eccentric hole of the revolving main shaft 5 through the needle roller bearings 6 and angular contact bearings 23 arranged at both ends thereof. The sleeve 3 drives the entire spindle system to complete the axial feed in the feed sliding sleeve 2, and the feed sliding sleeve 2 is installed in the feed base 1. The end of the adjustment shaft 13 and the revolving main shaft 5 is provided with an electromagnetic brake 28 capable of locking the relative positions of the two and a torque motor 29 for adjusting the axial distance between the high-spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com