Oilfield associated gas recycling and produced sewage treatment device based on aqueous-complex method

A sewage treatment device and oilfield associated gas technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, mining wastewater treatment, etc., can solve the problem of large consumption of medicines, difficulty in forming a scale, and low cost of filtration method and other issues, to achieve the effect of unified operation management, mutual utilization, and investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

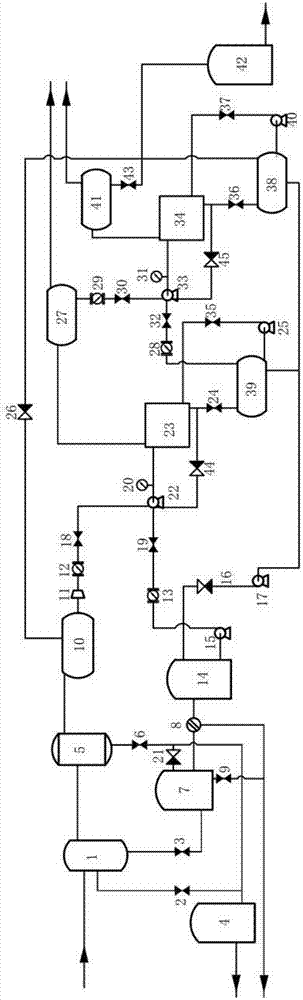

[0016] As shown in the accompanying drawings, the recovery method is: the device of the present invention comprises an oil-gas-water three-phase separator 1, a first gas-liquid-solid three-phase separator 38, a second gas-liquid-solid three-phase separator 39, a crude oil storage tank 4, Settling tank 7, condensation tower 5, filter 8, sewage tank 14, gas buffer tank 10, first screw pump 15, second screw pump 17, first slurry pump 25, second slurry pump 40, first gas-liquid two Phase pump 22, second gas-liquid two-phase book 33, compressor 11, first pressure gauge 20, second pressure gauge 31, first flowmeter 12, second flowmeter 13, third flowmeter 28, fourth flowmeter 29. The first hydrate formation and decomposition unit 23, the second hydrate formation and decomposition unit 34, the first one-way valve 16, the third one-way valve 26, the second one-way valve 21, the fourth one-way valve 44, the fifth one-way valve Check valve 45, first stop valve 2, second stop valve 3, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com