Heat pipe heat recovery type purification fresh air ventilator

A heat recovery, fresh air fan technology, applied in heat recovery systems, heating methods, space heating and ventilation, etc., can solve the problems of low heat recovery efficiency, easy icing life, large resistance, etc., to improve the exchange of cold and heat. Efficiency, saving operating costs and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

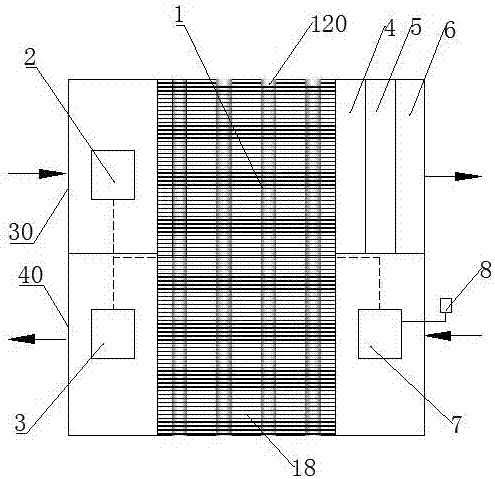

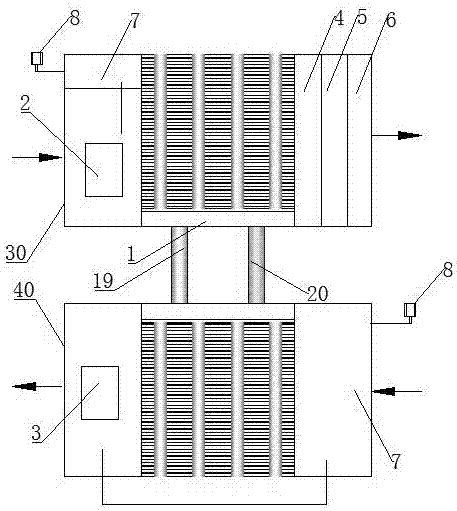

[0040] Such as figure 1 , 2 As shown, a heat pipe heat recovery type purifying fresh air blower includes a heat pipe type heat exchanger 1. One end of the heat pipe type heat exchanger 1 is arranged in the fresh air duct 30 of the purifying fresh air blower, and the other of the heat pipe type heat exchanger 1 One end is arranged in the exhaust duct 40 of the purifying fresh air blower, in the fresh air duct 30: the fresh air fan 2 is arranged on one side of the heat pipe type heat exchanger 1, and in the exhaust duct 40: the heat pipe type heat exchanger 1 An exhaust fan 3 is provided on one side, and the above-mentioned fresh air fan 2 and exhaust fan 3 are both signally connected to the monitoring and control module 7.

[0041] The fresh air blower in this embodiment involves two working conditions, namely summer cold recovery and winter heat recovery conditions. For summer cold recovery conditions: outdoor at around 35°C, indoor at around 25°C, and 35°C fresh air The fresh ai...

Embodiment 2

[0043] Optimized on the basis of Example 1, in the fresh air duct 30: the side of the heat pipe heat exchanger 1 opposite to the fresh air fan 2 is provided with a purification module 4, a sterilization module 5, and an anion sterilization module 6 in sequence along the wind direction. The monitoring and control module 7 is also signally connected with an air quality sensor 8 for detecting indoor and outdoor air quality.

[0044] In this embodiment, the fresh air generated in the fresh air duct is transformed into clean warm oxygen-enriched fresh air through air quality processing modules such as purification modules, sterilization modules, and negative ion modules, and is sent indoors. The air quality sensor is used to detect indoors and outdoors. In order to improve the indoor air quality by controlling the fresh air fans as needed.

Embodiment 3

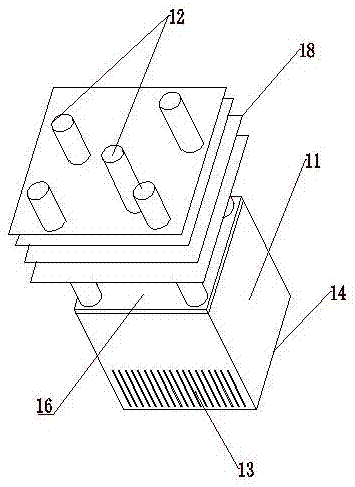

[0046] Optimized on the basis of embodiment 1 or 2, the above-mentioned heat pipe heat exchanger 1 is an integral heat pipe group, such as figure 1 As shown, the above-mentioned integrated heat pipe group is composed of two or more heat pipes 120 arranged side by side. The heat pipe is fitted with radiating fins 18 perpendicular to the axial direction of the heat pipe 120. One end of the heat pipe 120 is located in the exhaust duct 40, The other end is located in the new air duct 30.

[0047] In this embodiment, the heat pipe heat exchanger 1 adopts an integral heat pipe group, one end of the heat pipe group is the evaporating end, and the other end of the heat pipe group is the condensing end, and the exhaust duct is completely sealed and isolated from the fresh air duct to ensure no air leakage. The heat dissipation fins help increase the heat dissipation area, thereby speeding up heat dissipation and improving heat transfer efficiency.

[0048] For the summer cold recovery condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com