Industrial air purification system

An air purification system, an industrial technology, applied in the field of air pollutant control, can solve problems such as pollution, resource waste, cost loss, etc., to achieve the effect of improving dust collection efficiency, prolonging residence time, and avoiding excessive dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

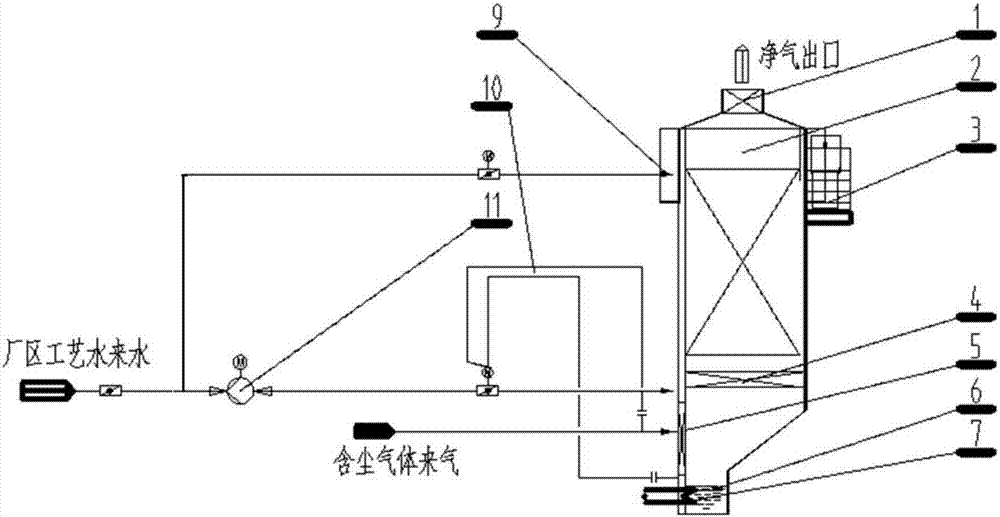

[0060] Combine below figure 1 A specific embodiment of the present invention is given.

[0061] as attached figure 1As shown, the dust-laden airflow (concentration of tens of grams to hundreds of grams / cubic meter) produced in the industrial production process first enters the dust removal section of the 5 louvers under the suction of the 1 diagonal flow fan, and intercepts the particles above 50 microns. The dust accumulated in the dust removal section of the louver enters the waste liquid tank 6 under the action of the 10 spray flushing device. cubic meter) into the 4 high-efficiency separation tank plate dedusting section, and most of the particles above 10 microns are intercepted, and the dust intercepted by the high-efficiency separation tank plate dedusting section enters the waste liquid tank 6 under the effect of the 10 spray flushing devices; The airflow (concentration tens of milligrams to hundreds of milligrams per cubic meter) enters the 2 electrostatic precipita...

Embodiment 2

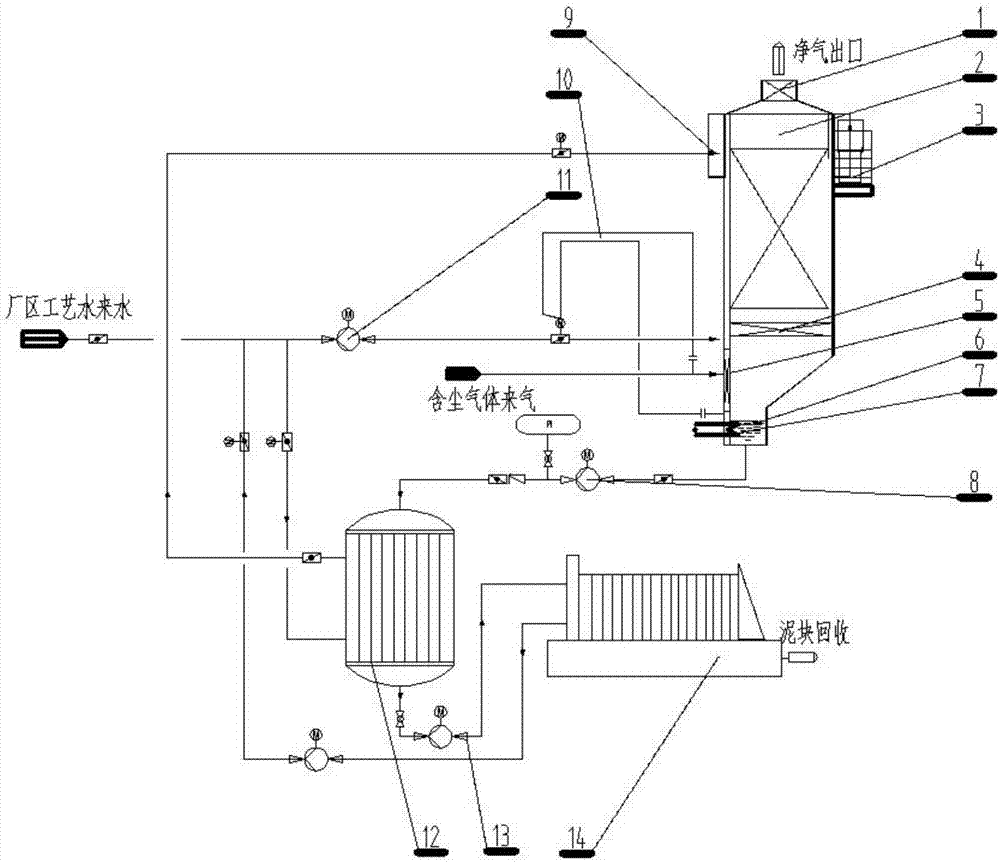

[0064] Combine below figure 2 A best specific embodiment of the present invention is given.

[0065] as attached figure 2 As shown, the dust-laden airflow (concentration of 10 g to 800 g / m3) produced in the production process of the metallurgical industry first enters the dust removal section of the 5 louvers under the suction of the 1 oblique flow fan, and intercepts the particles above 50 microns. Under the action of the 10 spray flushing device, it enters the 6 waste liquid tank, and the water of the 10 spray flushing device comes from the clear liquid of the 12 multi-tube filter, the clear liquid of the 14 filter press and the process water of the factory area are replenished through the 11 water pump; Then the air flow (with a concentration of 100 mg ~ 10 g / m3) enters the dust removal section of the 4 high-efficiency separation tank plate, and most of the particles above 10 microns are intercepted, and the intercepted dust enters the 6 waste liquid tank under the actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com