Casting machining method for liquid droplet cake-shaped bouncing large-size super-hydrophobic cylindrical array

A processing method, super-hydrophobic technology, applied in the direction of coating, etc., can solve the problems of difficult to realize industrialized large-area processing, low EDM efficiency, high aspect ratio, etc., and achieve easy processing, low density, and high aspect ratio low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

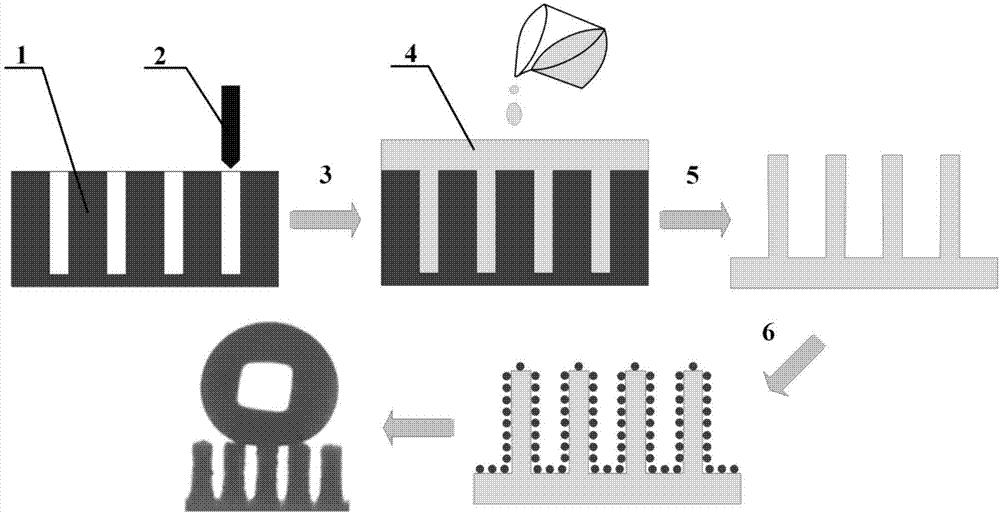

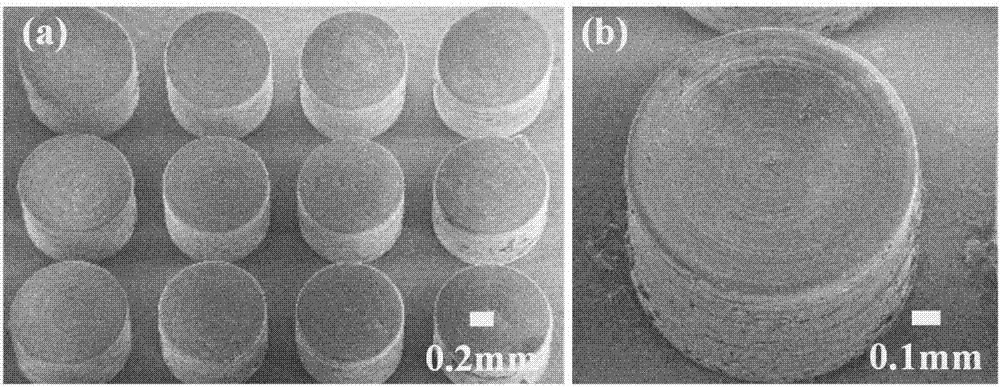

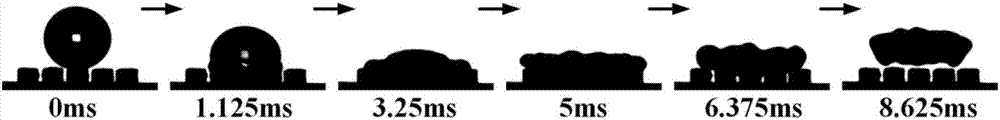

[0024] Using a porous array template casting replication method to fabricate superhydrophobic cylindrical arrays that can achieve droplet cake bounce, such as figure 1 As shown, the specific method is as follows:

[0025] (1) Prepare the pouring mold: use 800# and 1500# sandpaper to polish the 6061 aluminum plate with a thickness of 2mm and ultrasonically clean it with deionized water to remove the surface oxide layer and oil; The 1.0mm array blind hole structure is polished with 1500# sandpaper to remove surface burrs, ultrasonically cleaned with deionized water and dried, and finally placed in a pouring container;

[0026] (2) Casting and curing: mix the PDMS module glue main agent and the crosslinking agent in a mass ratio of 10:1, and when the two are mixed evenly and are transparent and low-viscosity, pour the mold prepared in step 1; after pouring The whole is placed in a vacuum environment for defoaming treatment for 30 minutes, then vacuum cured at 70°C for 2 hours an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com