Preparation method for polyimide-based composite aerogel and polyimide-based composite aerogel

A composite airgel and polyimide-based technology, which is applied in the field of preparation of new nanomaterial-polymer-based porous composite airgel, can solve the problems of limited use, flammability, poor thermal stability, etc., and achieve design Ingenious ideas, low cost, excellent mechanical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

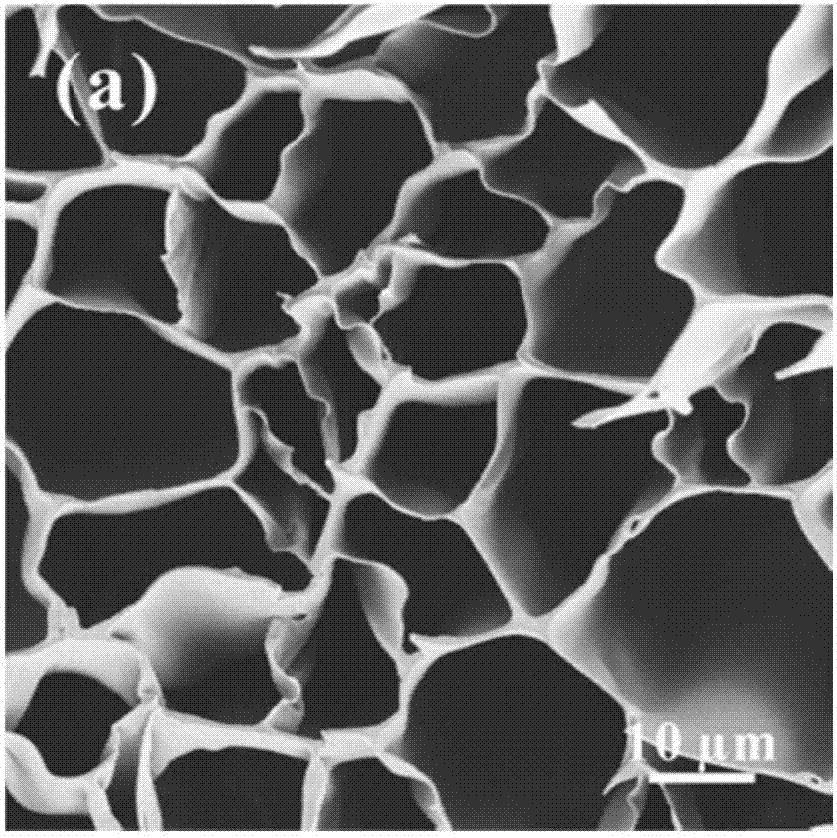

[0033] Take 30 mL of deionized water, add 2 g of polyamic acid and 1 g of triethylamine, sonicate for 1 h, and stir for 0.5 h to dissolve and disperse the polyamic acid evenly to obtain an aqueous solution of polyamic acid. Triethylamine can be coated on the terminal carboxyl functional group of polyamic acid, so that polyamic acid is easily soluble in deionized water. Then transfer it to a mold and ultrasonically for 0.5h, then transfer the mold to a refrigerator at about 4°C for 5h pre-cooling, then put it in liquid nitrogen to make it solid quickly, and then freeze it under a vacuum of 10-20Pa Dry for 48 hours to obtain polyamic acid airgel.

[0034] Place the obtained polyamic acid airgel in a tube furnace, and control the temperature rise program in a nitrogen atmosphere, that is, from room temperature to 100°C, heat up for 30 minutes, and hold for 1 hour; from 100°C to 200°C, heat up for 30 minutes, and hold for 1 h...

Embodiment 2

[0036] This embodiment includes the following steps:

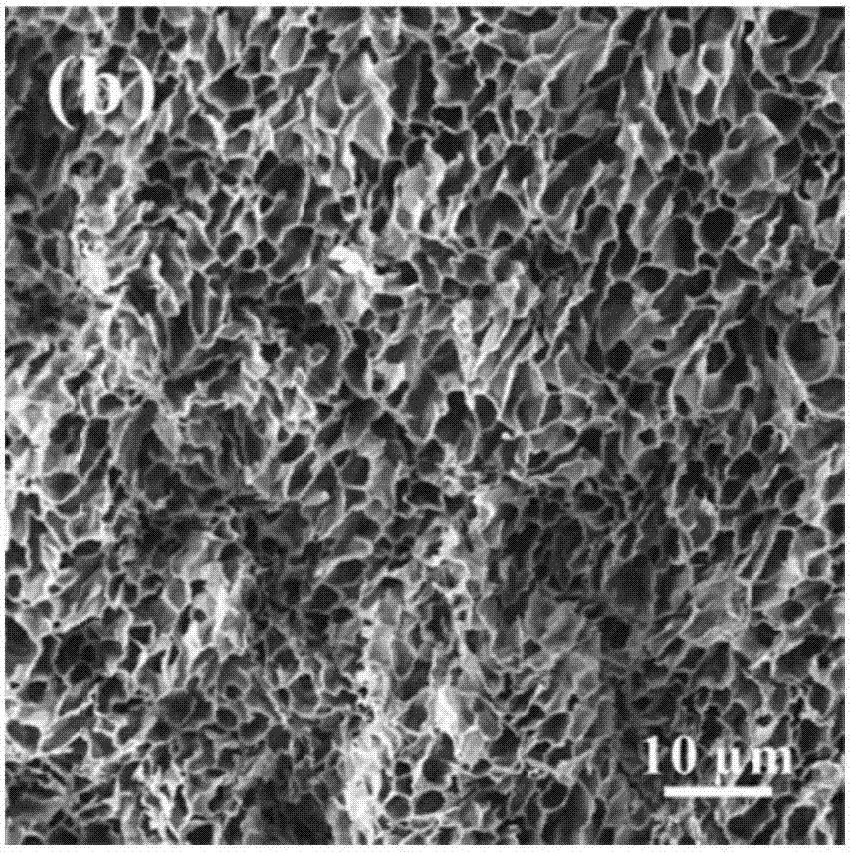

[0037] Take 30 mL of 2 mg / mL graphene oxide dispersion, add 2 g of polyamic acid and 1 g of triethylamine, sonicate for 1 h, and stir for 0.5 h to dissolve and disperse the polyamic acid evenly to obtain an aqueous solution of polyamic acid. All the other steps are the same as in Example 1. A graphene-enhanced polyimide-based composite airgel was obtained, denoted as PI / GO. The oxygen-containing group content of PI / GO was measured to be 36.8% by thermogravimetric analysis (TGA) and X-ray electron spectroscopy (XPS).

Embodiment 3

[0039] This embodiment includes the following steps:

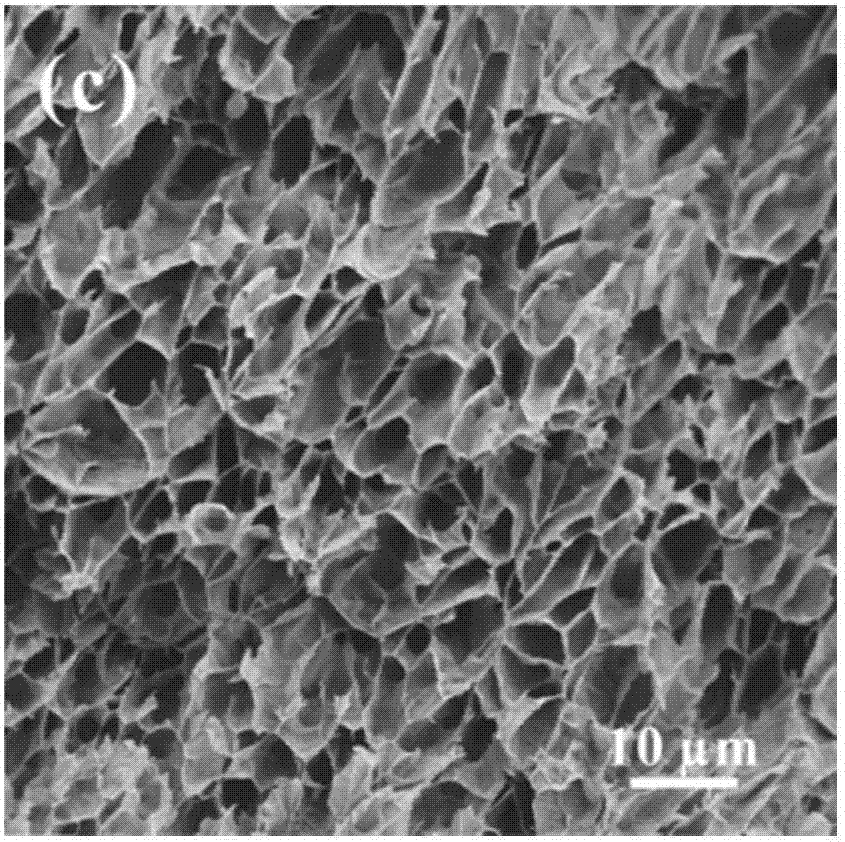

[0040] Take 30 mL of 2 mg / mL graphene oxide dispersion, add 11 μL of 50 wt% hydrazine hydrate and 75 μL of 25 wt% ammonia water, and stir at 95° C. for 0.5 h. Obtain a partially reduced graphene oxide dispersion, denoted as GO 30 .

[0041] The steps for preparing polyimide-based composite airgel are the same as in Example 1. A polyimide-based composite airgel reinforced with graphene (the product of partially reduced graphene oxide through thermal imidization) was obtained, denoted as PI / G 30 . PI / G was measured by TGA and XPS methods 30 The oxygen-containing group content is 32.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com