Anode material, preparation method of anode material, and lithium ion battery comprising anode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor high-temperature performance, unsatisfactory lithium-ion batteries, and unsatisfactory high- and low-temperature cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

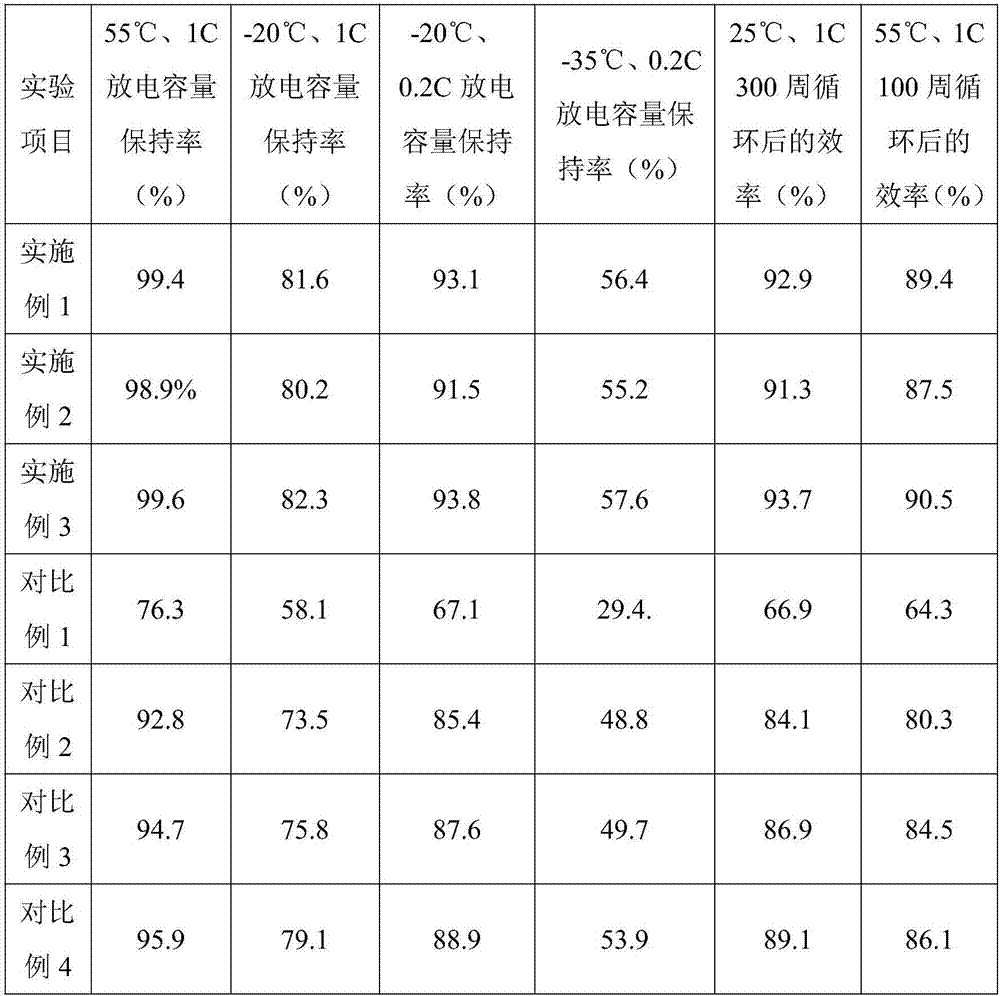

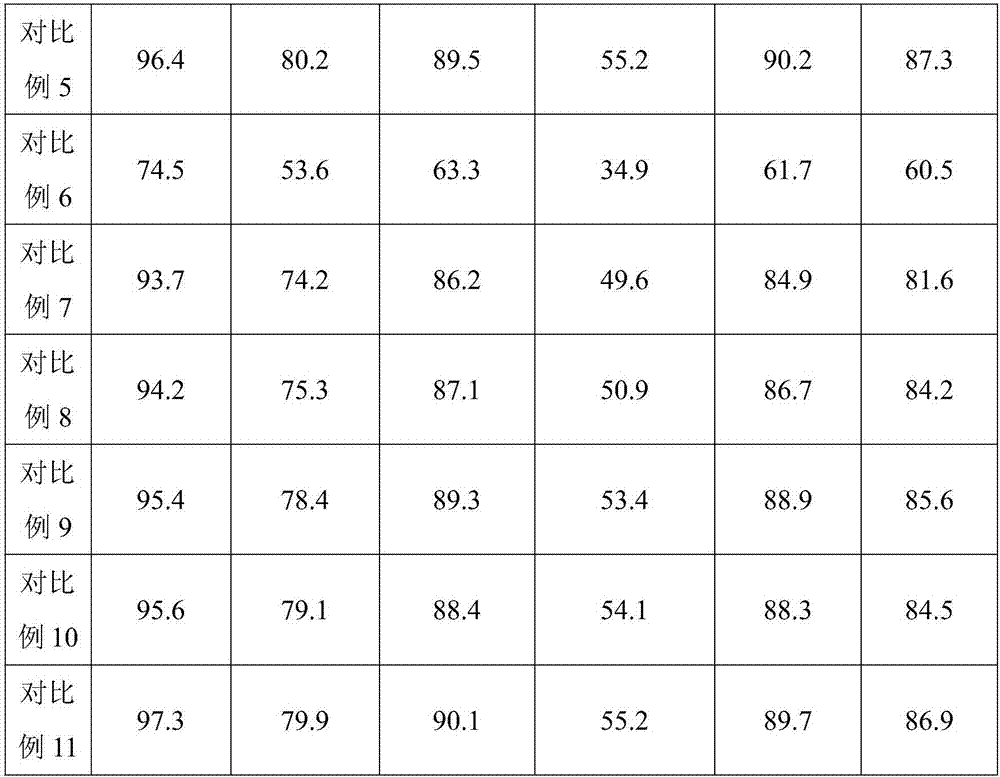

Examples

preparation example Construction

[0032] The preparation method of the positive electrode material comprises the following steps:

[0033] S1: Stir the graphene for 20-45min at a magnetic field strength of 4500-6000GS, an ultrasonic power of 200-550W, a temperature of 42-55°C, and a rotation speed of 200-300r / min to obtain graphene energy powder;

[0034] S2: Add sodium cetylbenzenesulfonate to the graphene energy powder that step S1 makes, the mass ratio of described graphene energy powder and sodium cetylbenzenesulfonate is 3-8:1, at temperature Activated at 50-72°C for 1.2-2.5 hours at a rotation speed of 100-150r / min to obtain activated graphene;

[0035] S3: 0.4-0.8 parts of activated graphene prepared in step S2, 0.6-1.3 parts of Ketjen black, 2-4 parts of ethylene-vinyl acetate copolymer, 0.5-1 part of ethylene bisstearamide, 210- Add 300 parts into a high-shear dispersing emulsifier for emulsification and dispersion for 2-3 hours to prepare mixture A;

[0036] S4: Add 85-92 parts of powdered nickel c...

Embodiment 1

[0046] A positive electrode material, in parts by weight, comprising the following raw materials: 90 parts of nickel-cobalt lithium manganese oxide, 1.6 parts of boron fiber, 2.5 parts of silicon nitride, 0.6 part of activated graphene, 1 part of Ketjen black, ethylene-vinyl acetate 3 parts of copolymer, 0.8 parts of ethylene bis stearamide, 1.5 parts of chlorinated polyethylene, 0.5 parts of fatty acid stabilizer.

[0047] The preparation method of the positive electrode material comprises the following steps:

[0048] S1: Stir the graphene for 32 minutes at a magnetic field strength of 5500GS, an ultrasonic power of 40W, a temperature of 50°C, and a rotation speed of 250r / min to obtain graphene energy powder;

[0049] S2: Add sodium hexadecylbenzene sulfonate to the graphene energy powder that step S1 makes, the mass ratio of described graphene energy powder and sodium hexadecylbenzene sulfonate is 6:1, at a temperature of 65 ℃, activated at 130r / min for 2h to produce activ...

Embodiment 2

[0061] A positive electrode material, in parts by weight, comprising the following raw materials: 86 parts of nickel-cobalt lithium manganese oxide, 1 part of boron fiber, 2 parts of silicon nitride, 0.4 part of activated graphene, 0.6 part of Ketjen black, ethylene-vinyl acetate 2 parts of copolymer, 0.5 parts of ethylene bis stearamide, 1.2 parts of chlorinated polyethylene, 0.4 parts of fatty acid stabilizer.

[0062] The preparation method of the positive electrode material comprises the following steps:

[0063] S1: Stir the graphene for 45 minutes at a magnetic field strength of 4500GS, an ultrasonic power of 200W, a temperature of 42°C, and a rotation speed of 200r / min to obtain graphene energy powder;

[0064] S2: Add sodium hexadecylbenzene sulfonate to the graphene energy powder that step S1 makes, the mass ratio of described graphene energy powder and sodium hexadecylbenzene sulfonate is 3:1, at a temperature of 50 ℃, activating at 100r / min for 2.5h to produce acti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com