Tackifying high-strength emulsified asphalt for surface treatment and preparation method of tackifying high-strength emulsified asphalt

An emulsified asphalt, surface technology, applied in building components, building insulation materials, buildings, etc., to achieve the effect of improving bonding performance and improving high and low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

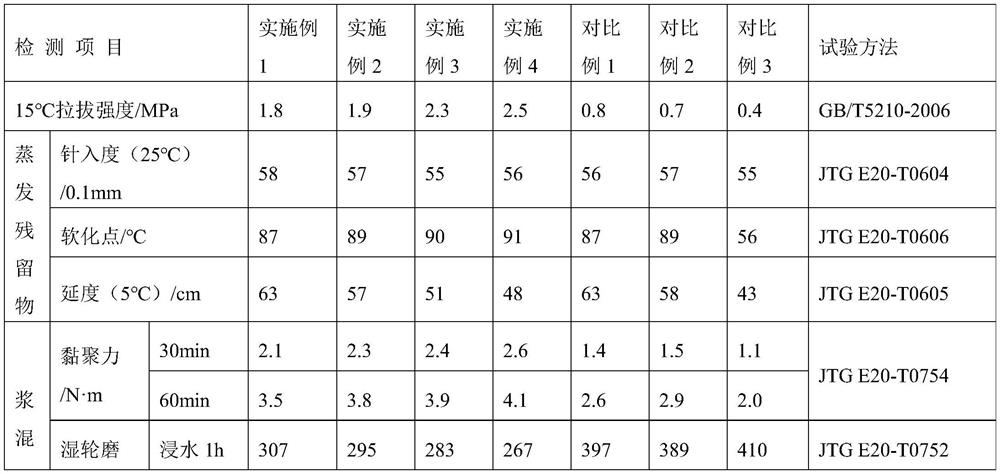

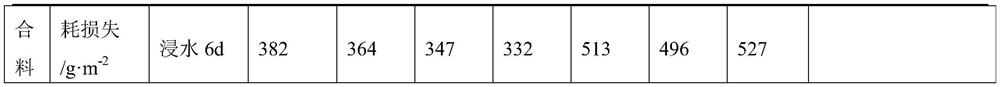

Examples

Embodiment 1

[0067] Example 1: A viscosified high-strength emulsified asphalt and its preparation method

[0068] The thickened high-strength emulsified asphalt provided in this example includes 95 parts of component A and 5 parts of component B in parts by weight.

[0069] Calculated according to parts by weight, the preparation method of component A is as follows:

[0070] S1. Heat 617 parts of SK90# asphalt to 160°C, add 6.5 parts of rubber oil and 26 parts of SBS elastomer successively, control the temperature at 180°C, use high-speed shearing machine to cut, SBS elastomer is finely dispersed and evenly added 0.5 parts of sulfur, stirred and developed at 175°C for 3 hours to obtain 650 parts of modified asphalt for emulsification;

[0071] S2. Add 2.5 parts of emulsifier I into water, add hydrochloric acid, adjust the pH to 2.0, adjust the temperature to 65°C, and prepare 350 parts of soap liquid;

[0072] S3. Pass the 175°C modified asphalt and 65°C soap solution through the colloid...

Embodiment 2

[0086] Example 2: A viscosified high-strength emulsified asphalt and its preparation method

[0087] The thickened high-strength emulsified asphalt provided in this example includes 95 parts of component A and 5 parts of component B in parts by weight.

[0088] The preparation method of A component is with embodiment 1.

[0089] Calculated according to parts by weight, the preparation method of B component is as follows:

[0090] A1. Take 200 parts of petroleum ether solvent with a boiling range of 60-90°C, add 24 parts of rosin resin into it, stir to make it dispersed and dissolved;

[0091] A2. Add 40 parts of alkylphenol-formaldehyde resin to rosin resin petroleum ether solvent, and shear and disperse within the temperature range of 35°C±3°C to obtain a mixed resin solution;

[0092] A3, adding petroleum ether resin solution and 40 parts of emulsifier II soap liquid (containing 4 parts of emulsifier II) to the colloid mill for emulsification to obtain emulsified resin sol...

Embodiment 3

[0096] Example 3: A viscosified high-strength emulsified asphalt and its preparation method

[0097] The thickened high-strength emulsified asphalt provided in this example includes 95 parts of component A and 5 parts of component B in parts by weight.

[0098] Calculated according to parts by weight, the preparation method of component A is as follows:

[0099]S1. Heat 597.5 parts of Zhenhai 70# asphalt to 160°C, add 26 parts of rubber oil and 26 parts of SBS elastomer successively, control the temperature at 180°C, and use a high-speed shearing machine to cut. After the SBS elastomer is finely dispersed and uniform Add 0.5 parts of sulfur, stir and develop at 175°C for 3 hours to obtain 650 parts of modified asphalt for emulsification;

[0100] S2. Add 3 parts of emulsifier I into water, add hydrochloric acid, adjust the pH to 2.0, adjust the temperature to 65°C, and prepare 350 parts of soap liquid;

[0101] S3. Pass the 175°C modified asphalt and 65°C soap solution throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com