Color-preserving agent for dried flowers, preparation method and color-preserving method

A technology for color retention agent and dried flower, applied in the field of plant color protection agent, can solve the problems of loss of color and fragrance of flowers, affecting the appearance of dried flowers, etc., and achieve the effects of prolonged fading time, remarkable color retention effect and simple composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

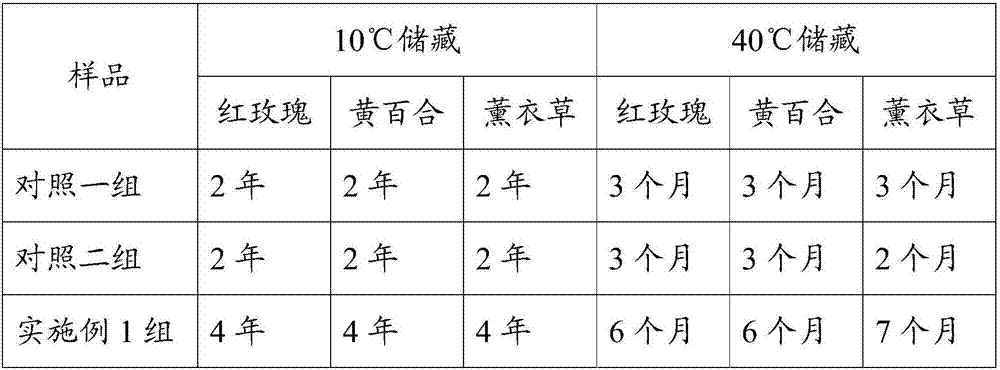

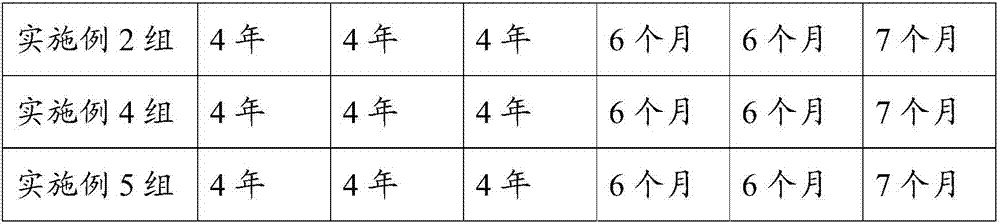

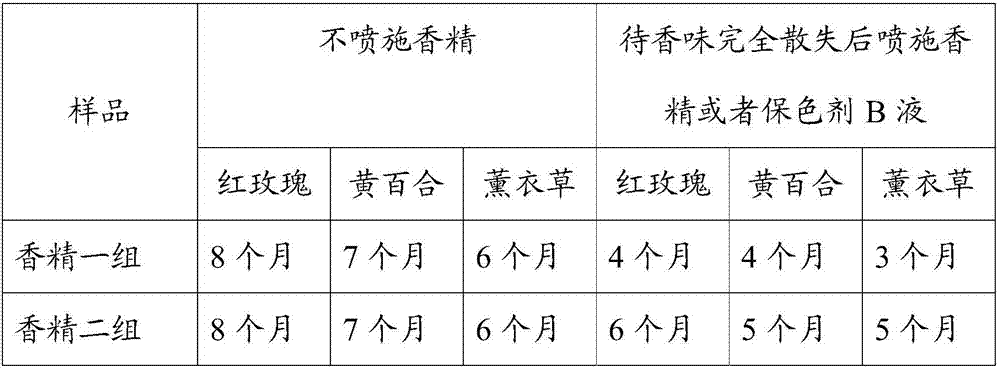

Examples

Embodiment 1

[0028] A dry flower color retention agent, comprising A liquid and B liquid, said A liquid is made of the following components in mass percentage: sodium sulfite 6%, sodium bisulfite 6%, potassium chloride 1.5%, sodium chloride 0.85% , glycerin 1%, essence 0.03%, and the balance is water; the B liquid is made of the following components in mass percentage: sodium sulfite 6%, sodium bisulfite 6%, potassium chloride 1%, sodium chloride 0.9% , essence 0.2%, balance is water. Prepare as follows:

[0029] S1, weigh the components of liquid A according to the following mass percentages: 6% sodium sulfite, 6% sodium bisulfite, 1.5% potassium chloride, 0.85% sodium chloride, 1% glycerin, 0.03% essence, and the balance is water. The mass percentage sum of the above-mentioned components is 100%;

[0030] S2, heat the water weighed in step S1 to 60°C, then add the weighed emulsifier to fully dissolve the emulsifier, add the weighed sodium sulfite, sodium bisulfite, potassium chloride, ...

Embodiment 2

[0034] A dry flower color retention agent, comprising A liquid and B liquid, said A liquid is made of the following components in mass percentage: sodium sulfite 5%, sodium bisulfite 5%, potassium chloride 1%, sodium chloride 0.8% , sodium dodecylsulfonate 1.5%, essence 0.05%, and the balance is water; the B liquid is made of the following components in mass percentage: sodium sulfite 4%, sodium bisulfite 4%, potassium chloride 1.5% , 0.8% sodium chloride, 0.3% essence, and the balance is water. Prepare as follows:

[0035] S1, weigh the components of liquid A according to the following mass percentages: 5% sodium sulfite, 5% sodium bisulfite, 1% potassium chloride, 0.8% sodium chloride, 1.5% sodium dodecylsulfonate, 0.05% essence , the balance is water, and the mass percentage sum of the above-mentioned components is 100%;

[0036] S2, heat the water weighed in step S1 to 60°C, then add the weighed emulsifier to fully dissolve the emulsifier, add the weighed sodium sulfite,...

Embodiment 3

[0040] A dry flower color retention agent, comprising A liquid and B liquid, said A liquid is made of the following components in mass percentage: sodium sulfite 8%, sodium bisulfite 8%, potassium chloride 2%, sodium chloride 0.9% , glycerin 1.2%, essence 0.04%, and the balance is water; the B liquid is made of the following components in mass percentage: sodium sulfite 5%, sodium bisulfite 5%, potassium chloride 2%, sodium chloride 0.9% , essence 0.1%, balance is water. The preparation method is the same as in Example 1, except that the formula of the dried flower color retention agent is changed into that of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com