Composite optical printing paper and its preparation method

A technology of light printing paper and light-based printing paper, applied in the field of light printing, can solve the problems of moisture-proof, waterproof, anti-oxidation and mechanical properties of light printing paper, low color saturation of tungsten-based light printing paper, and preparation of light printing paper. The technology needs to be improved and other issues to achieve the effect of prolonging the fading time, enhancing the color saturation, and enhancing the photochromic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] (1) Preparation of composite optical printing paper

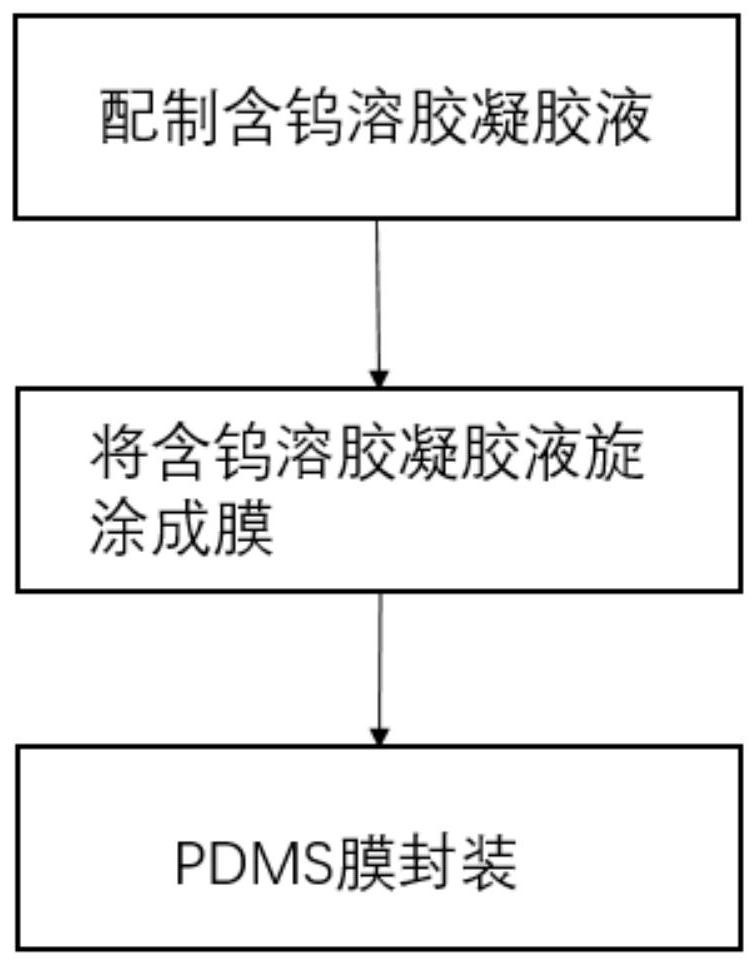

[0040] According to the preparation process of composite light printing paper provided by the present invention such as figure 1 shown.

[0041] In some embodiments, the preparation of the composite optical printing paper includes:

[0042] The first step: preparation of tungsten-containing sol-gel solution

[0043] Dissolve the tungsten-containing compound and high molecular polymer into the mixed solution of solvent and acid, and stir to obtain the tungsten-containing sol-gel liquid;

[0044] Step 2: Spin coating to form a film

[0045] The above tungsten-containing sol-gel solution is spin-coated to form a film, and after the solvent is volatilized, a tungsten-based photoprinting paper is obtained;

[0046] Step 3: PDMS membrane encapsulation

[0047] A PDMS solution is spin-coated on both sides of the tungsten-based photoprinting paper, and heat-treated to obtain a composite photoprinting paper reinforced wi...

Embodiment 1

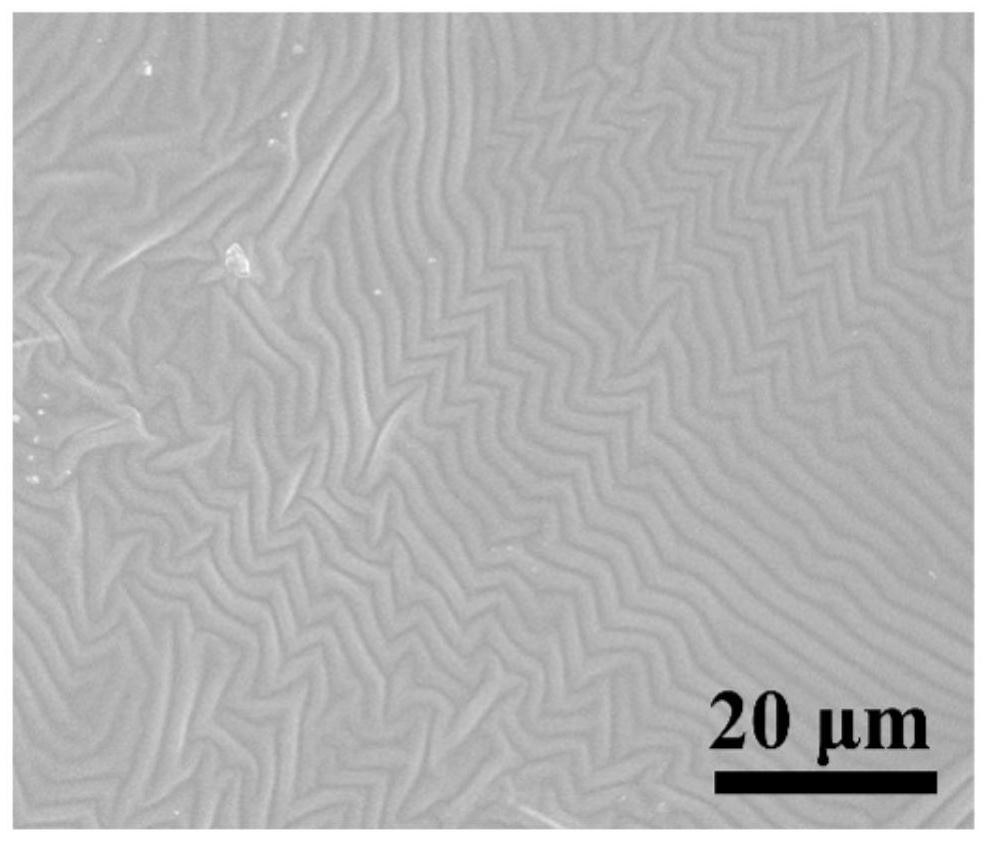

[0093] First, dissolve 4g of ammonium metatungstate and 2g of polyvinylpyrrolidone into a mixture of 3.5g of deionized water and 0.5g of concentrated sulfuric acid, and magnetically stir until fully dissolved to obtain a precursor sol-gel solution; then use a high-speed homogenizer Spin-coat the precursor sol-gel solution on the surface of the substrate to form a uniform and smooth film, and let it stand at room temperature for 1 hour until part of the solvent volatilizes to obtain tungsten-based optical printing paper for use; finally, spin-coat the two sides of the above-mentioned tungsten-based optical printing paper A layer of PDMS liquid was placed in an oven and kept at 80°C for 2 hours to obtain composite photoprinting paper reinforced with PDMS microstructure wrinkled film.

Embodiment 2

[0095] First, dissolve 4g of ammonium metatungstate and 2g of polyvinylpyrrolidone into a mixture of 3.5g of deionized water and 0.5g of formic acid, and magnetically stir until fully dissolved to obtain a precursor sol-gel solution; then use a high-speed homogenizer to The precursor sol-gel solution was spin-coated on the surface of the substrate to form a uniform and flat film, and left at room temperature for 1 hour to allow part of the solvent to volatilize to obtain tungsten-based optical printing paper for use; finally, spin-coat a A layer of PDMS liquid was placed in an oven and kept at 80°C for 2 hours to obtain composite photoprinting paper reinforced with PDMS microstructure wrinkled film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com