Black tea fermentation tank

A fermentation tank and black tea technology, applied in tea treatment before extraction, etc., can solve problems such as difficult to meet the needs of black tea fermentation production, unacceptable for small tea farms, large investment in plant construction, etc., and achieve simple structure, small construction investment, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

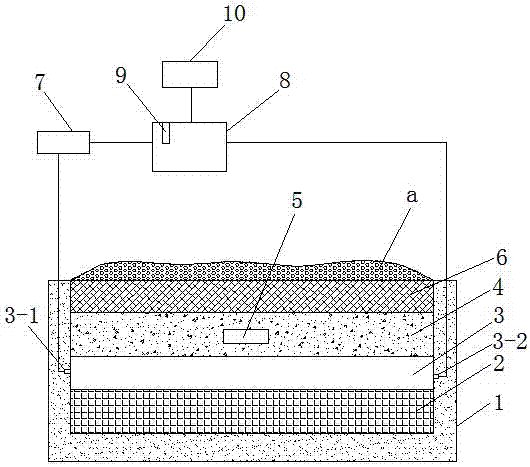

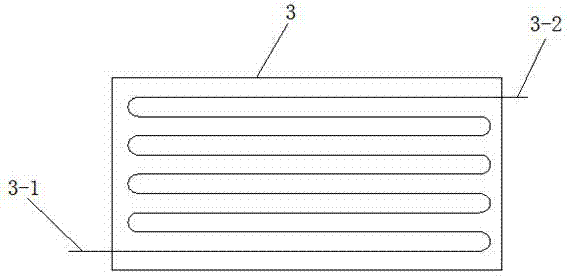

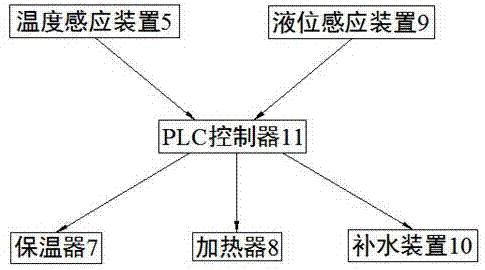

[0015] like Figure 1-Figure 3 As shown, the present embodiment adopts the following technical solutions: it includes a pool body 1, an insulation layer 2, a water pipe layer 3, a water inlet 3-1, a water outlet 3-2, a sandstone layer 4, a temperature sensing device 5, and a cement layer 6. Incubator 7, heater 8, liquid level sensing device 9, water supply device 10 and PLC controller 11, the bottom of the pool body 1 is provided with an insulation layer 2, and a water pipe layer 3 is laid above the insulation layer 2 , the water pipe layer 3 adopts a folded and tiled design, which has a large heat dissipation area and good heating effect. A sandstone layer 4 is laid above the water pipe layer 3, and a temperature sensing device 5 is installed inside the sandstone layer 4. Through the temperature sensing device 5, the temperature inside the sandstone layer 4 can be found in time, and then according to the needs, the hot water in the incubator 7 is controlled by the PLC control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com