Preparation method and application of heavy metal chelating agent

A heavy metal chelating agent and chelating agent technology, applied in the field of fly ash treatment, can solve the problems of deviation of lead treatment effect, high cost of chemicals, deviation of nickel effect, etc., so as to improve the operation safety, improve the working environment, and prevent the overflow of ammonia. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

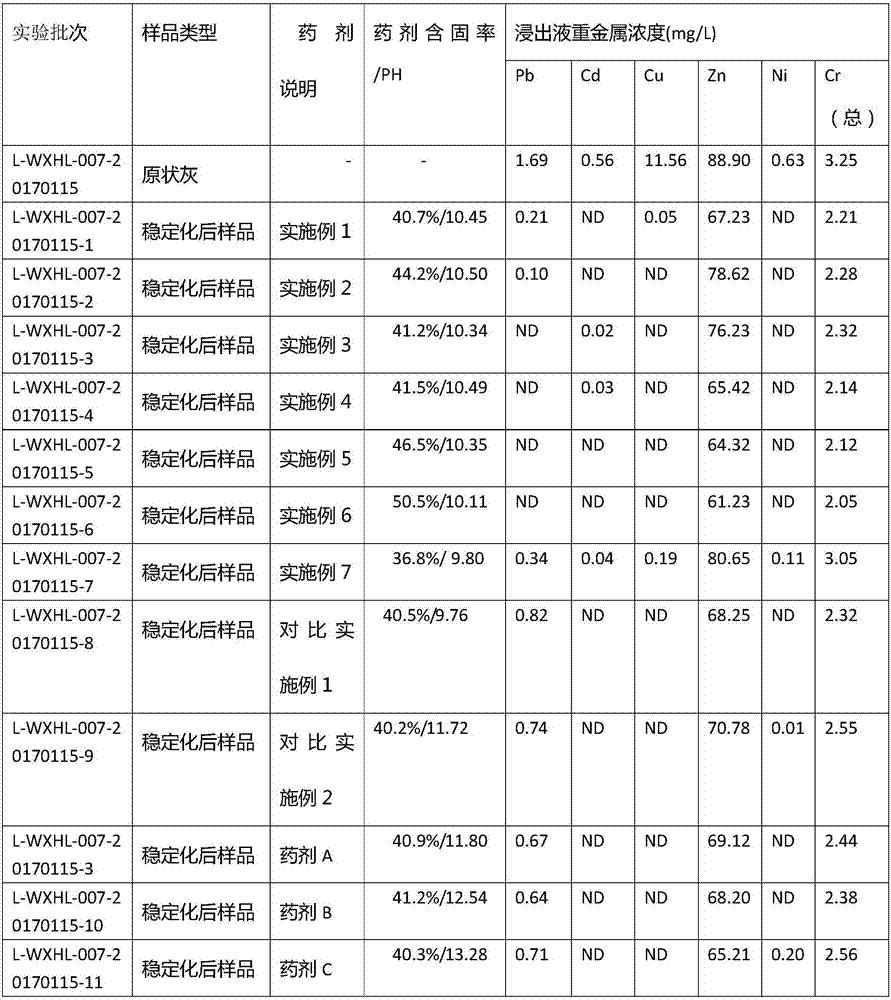

Embodiment 1

[0023] (1) Add 450kg of reaction bottom water into the reaction kettle, stir and add 421kg of dimethyl dithiocarbamate, adjust the temperature to 40°C, and stir for 2 hours.

[0024] (2) Slowly add 100 kg of sodium formate solution dropwise, control the pH value to 9, add dropwise for 0.5 hour, and stir steadily for 1 hour.

[0025] (3) Slowly add 50 kg of hydrazine hydrate solution dropwise, stir and keep warm for 2 hours.

[0026] (4) Cool down, check the content, the solid content is 40.7%, and the pH is 10.45.

Embodiment 2

[0028] (1) Add 500kg of reaction bottom water into the reaction kettle, stir and add 452kg of diethyldithiocarbamate, adjust the temperature to 50°C, and stir for 2 hours.

[0029] (2) Slowly add 50 kg of sodium gluconate solution dropwise, and stir and keep warm for 5 hours.

[0030] (3) Slowly add 20 kg of thiourea solution dropwise, control the pH value to 10.5, add dropwise for 2 hours, and stir steadily for 3 hours.

[0031] (4) Cool down, check the content, the solid content is 44.2%, and the pH is 10.50.

Embodiment 3

[0033] (1) Add 400kg of reaction bottom water into the reaction kettle, stir and add 421kg of ureidene dithiocarbamate, adjust the temperature to 55°C, and stir for 1 hour.

[0034] (2) Slowly add 100 kg of disodium phosphate solution dropwise, control the pH value to 9.5, add dropwise for 1.5 hours, and stir steadily for 2 hours.

[0035] (3) Slowly add 30 kg of carbazide solution dropwise, stir and keep warm for 3 hours.

[0036] (4) Cool down, check the content, the solid content is 41.2%, and the pH is 10.34.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com