Preparation method for MCM-41 loaded Pt and Al catalyst and application thereof

A technology of MCM-41 and catalyst, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of non-reusable heterogeneous catalysts, reduced catalytic activity, difficult separation of products, etc., and achieve improvement Platinum metal agglomeration phenomenon, improvement of catalytic activity, and effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

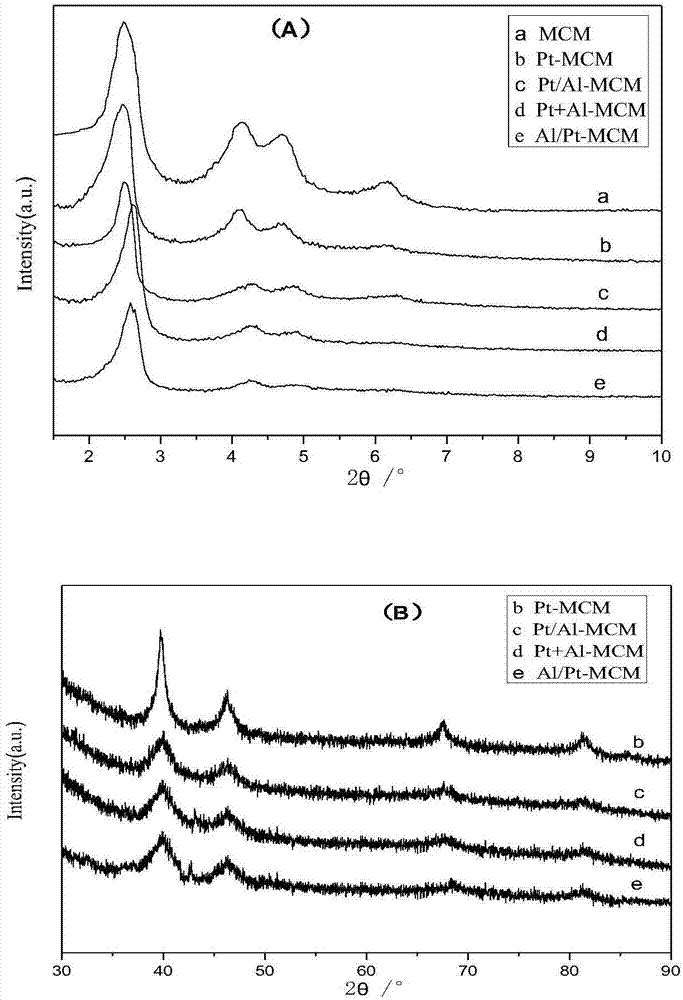

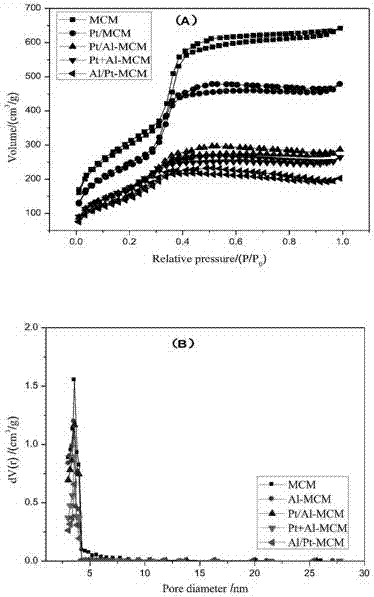

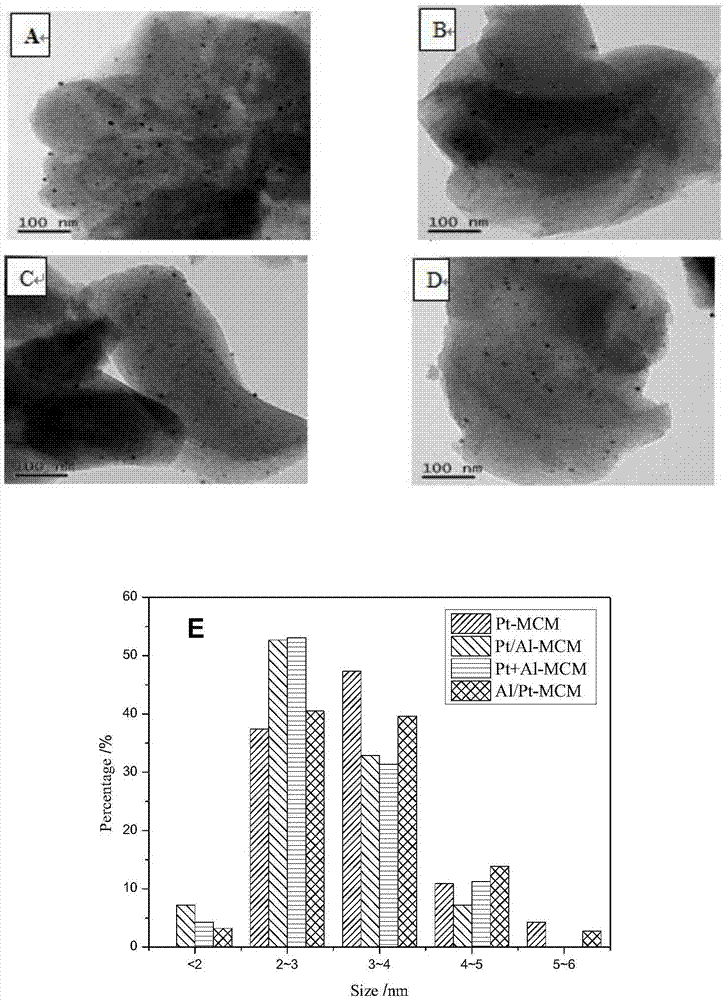

[0027] Example 1, see Figure 1-Figure 3 :

[0028] The invention provides a kind of preparation method of MCM-41 loaded Pt, Al catalyst, comprises the steps:

[0029] 1) Preparation of mesoporous silicon MCM-41:

[0030] Add 1.5g of CTAB, 120mL of distilled water and 80mL of concentrated ammonia water into a three-necked flask, stir at 60°C for 1 hour, then add 4.5g of ethyl orthosilicate, continue stirring for 7 hours, then stop the reaction, crystallize at room temperature, filter, wash, drying, acidified ethanol solution (V 盐酸 :V 乙醇 =1:20) to remove CTAB, and washed to neutral, and then roasted at 400°C for 2h to obtain mesoporous silicon MCM-41, denoted as MCM;

[0031] 2) Preparation of MCM-41 supported Pt and Al catalysts:

[0032] Weigh 1.0g of activated mesoporous silicon MCM-41 and 35mL of dehydrated ethanol into a three-necked flask, pass N 2 After 0.5h, add 10mL of chloroplatinic acid-ethanol solution, stir at 75°C for 10h, then evaporate the ethanol to dryne...

Embodiment 2

[0033] Example 2, see Figure 1-Figure 3 :

[0034] The preparation process of this embodiment is basically the same as that of Example 1, the difference being: first add aluminum chloride-ethanol solution, and then add aluminum chloride-ethanol solution to prepare MCM-41, which is loaded with Al first and then with Pt. Recorded as Pt / Al-MCM.

Embodiment 3

[0035] Example 3, see Figure 1-Figure 3 :

[0036] The preparation process of this embodiment is basically the same as that of Example 1, except that the preparation of MCM-41 supported Pt and Al catalysts:

[0037] Weigh 1.0g of activated mesoporous silicon MCM-41 and 65mL of dehydrated ethanol into a three-necked flask, pass N 2 After 0.5h, add 10mL of chloroplatinic acid-ethanol solution and 15mL of aluminum chloride-ethanol solution, stir at 75°C for 10h, filter with distilled water, and then dry in a vacuum desiccator at 50°C to obtain MCM- 41 The catalyst supporting Pt and Al at the same time is denoted as Pt+Al-MCM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com