Metal sphere producing equipment and metal sphere forming machine

A technology for production equipment and spheres, applied in metal processing equipment, metal extrusion control equipment, metal extrusion and other directions, can solve the problems of high production cost, small product specifications, poor quality, etc., and achieve improved product quality and dense organization. , high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

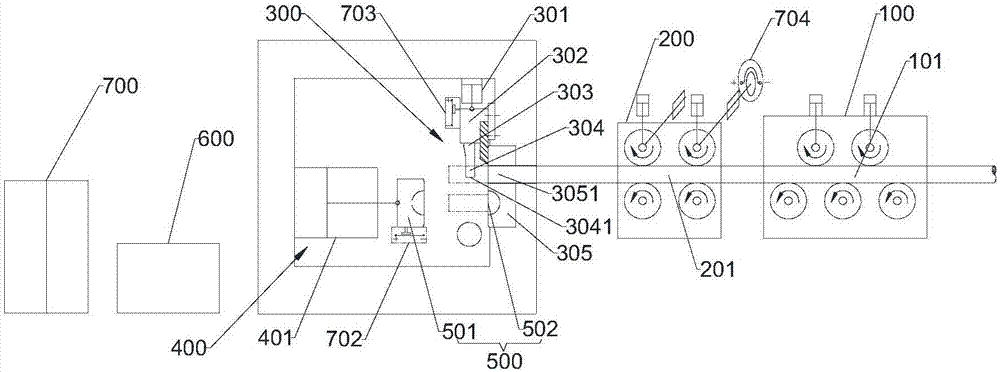

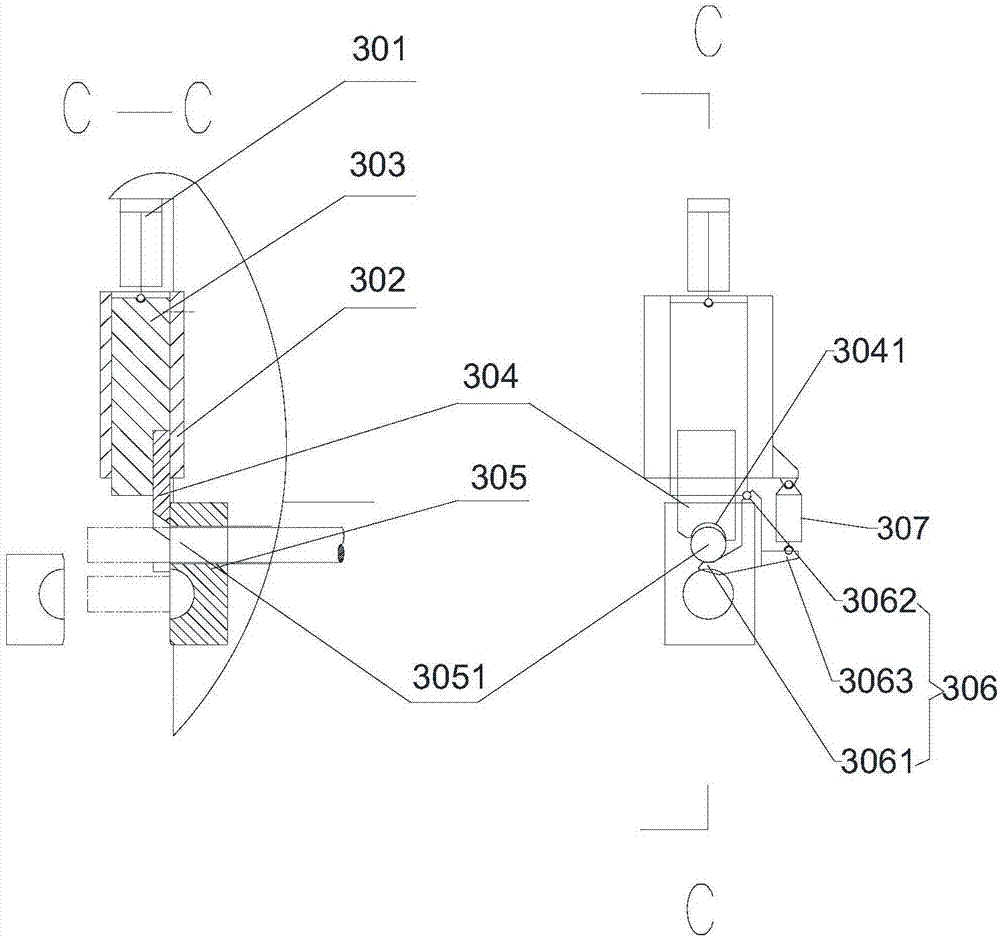

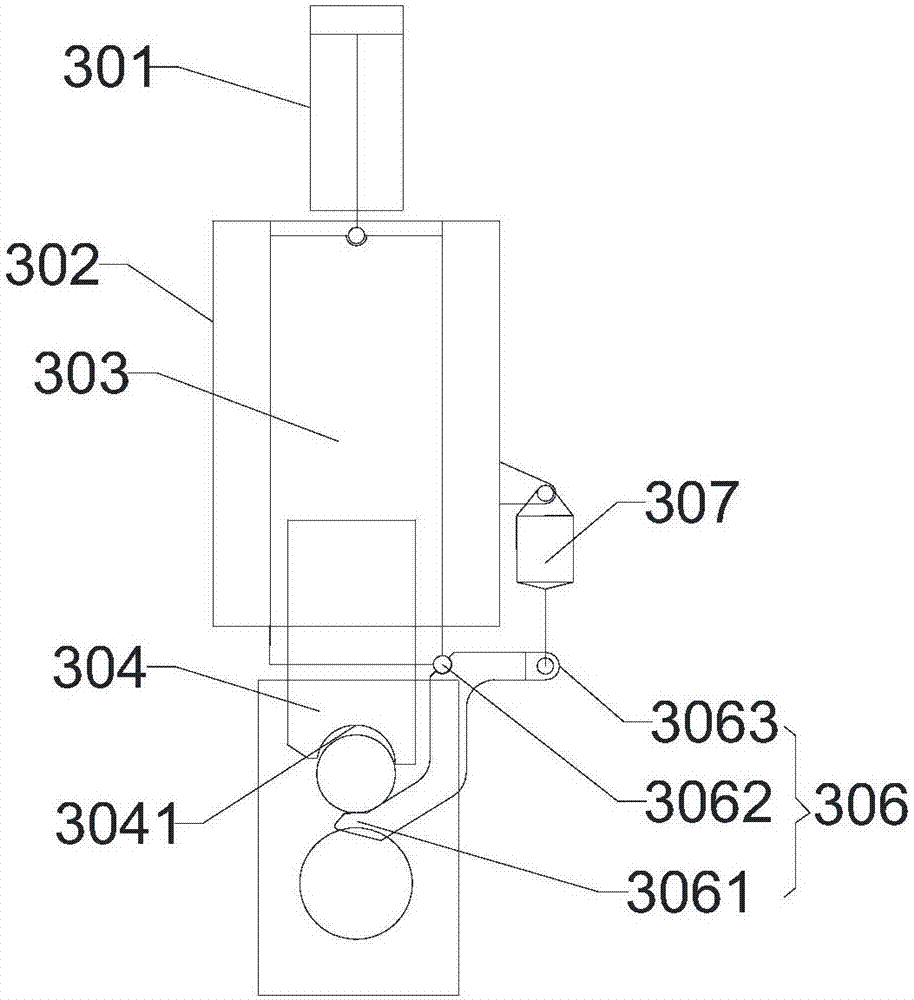

[0041] Embodiment 1, with reference to Figure 1 to Figure 7 .

[0042] The metal sphere production equipment provided in this embodiment is used for processing and forming metal spheres. The metal spheres include copper balls, iron balls, etc., and this embodiment is mainly used for processing and forming phosphor bronze balls.

[0043] Such as figure 1 As shown, the metal sphere production equipment provided in this embodiment includes a driving mechanism 400, a molding device 500, a hydraulic control system 600 and an electrical control system 700;

[0044] The driving mechanism 400 includes a first hydraulic cylinder 401, the molding device 500 includes a movable mold 501 and a fixed mold 502 that can cooperate with each other, the hydraulic control system 600 includes a hydraulic station, a control valve group and pipelines, and the electrical control system 700 includes an electrically connected controller and a first displacement detection device 702;

[0045] The fi...

Embodiment 2

[0097]The specific implementation of a microcrystalline copper ball automatic hydraulic forming machine provided in this embodiment is: the main structure consists of a feeding device, a pinch device, a straightening device, a fixed-length feeding device, a main machine, a blank cutting device, a copper Ball forming die device, ball ejecting device, slider assembly, hydraulic power device, ball receiving device, hydraulic control system, electrical control system; feeding device, pinch device, straightening device, length-feeding device, host level Installed on a flat foundation, the billet cutting device, copper ball forming die device, ball jacking device, slider assembly, hydraulic power device, and ball receiving device are installed in the frame, and the hydraulic control system and electrical control system are installed near the main machine ; The main technical feature is that the microcrystalline metal ball forming machine uses hydraulic pressure as the power to comple...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap