A special organic matter culture soil for indoor potted plants and its preparation method and application

A technology for culturing soil and organic matter, which is applied to the field of special organic matter culturing soil for indoor potted plants and its preparation, can solve the problems that the plant soil is easy to harden and lack water, fertilizer and air for a long time, and achieves good plant growth, loose physical properties, The effect of long-term slow release of soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

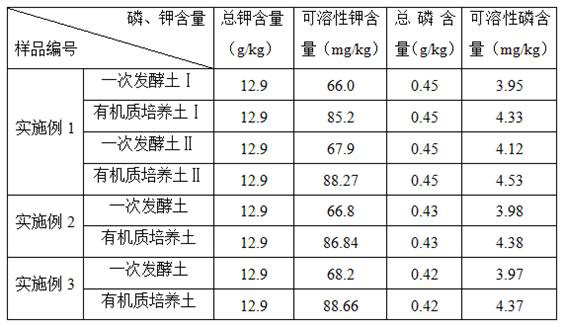

[0039] Table 1 The raw material composition table of the special organic matter culture soil for indoor potted plants in Examples 1-3

[0040]

[0041] Example 1 of the preparation method of special organic matter culture soil for indoor potted plants

[0042] (1) According to the parts by weight of the raw materials described in Example 1 in Table 1, the edible fungus residue, lettuce and tobacco leaf stems were crushed into powders with a particle size of 200 mesh;

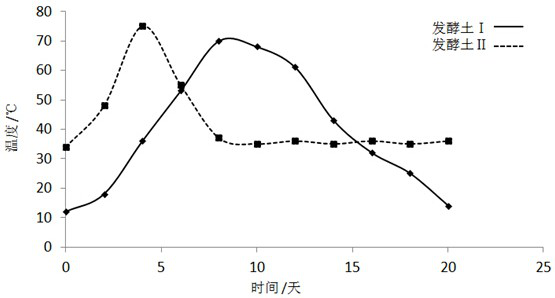

[0043] (2) According to the parts by weight of the raw materials described in Example 1 in Table 1, mix the powder obtained in step (1) with fresh chicken and duck manure and animal bone meal, stir evenly, add water to adjust the humidity to 70%, and cover it with stack retting , respectively, started on November 3, 2016, and carried out sealed fermentation for 15 days at a fermentation temperature of 13-70°C to obtain primary fermentation soil I; started on June 10, 2017, and carried out sealed fermentation ...

Embodiment 2

[0047] (1) According to the parts by weight of the raw materials described in Example 2 of Table 1, the edible fungus dregs, lettuce and tobacco leaf stems were crushed into powders with a particle size of 100 mesh;

[0048] (2) According to the parts by weight of the raw materials described in Table 1, Example 2, mix the powder obtained in step (1) with fresh chicken and duck manure and animal bone meal, stir evenly, add water to adjust the humidity to 50%, and cover it with stack retting , began on June 10, and carried out sealed fermentation for 7 days at a fermentation temperature of 28-73°C to obtain primary fermentation soil;

[0049] (3) According to the parts by weight of the raw materials described in Table 1, Example 2, add 100 mesh attapulgite, superphosphate and colloidal bacillus preparations to the fermented soil obtained in step (2), and stir evenly. Initially, at 30-35°C, carry out sealed secondary fermentation for 3 days to obtain organic matter culture soil. ...

Embodiment 3

[0051] (1) According to the parts by weight of the raw materials described in Example 3 of Table 1, the edible fungus dregs, lettuce and tobacco leaf stems were crushed into powders with a particle size of 20 mesh;

[0052] (2) According to the parts by weight of the raw materials described in Example 3 in Table 1, mix the powder obtained in step (1) with fresh chicken and duck manure and animal bone meal, stir evenly, add water to adjust the humidity to 90%, and store it in a container Among them, starting from June 10, the sealed fermentation was carried out for 8 days at a fermentation temperature of 28-75°C to obtain a primary fermentation soil, and some samples were taken for testing;

[0053] (3) According to the parts by weight of the raw materials described in Example 3 of Table 1, add 300-mesh attapulgite, superphosphate and colloidal bacillus preparations to the fermented soil obtained in step (2), and stir evenly. Initially, at 30-33°C, carry out sealed secondary fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com