Synthesis method of high-purity 1-pyrenecarboxaldehyde

A synthesis method, the technology of pyrene formaldehyde, is applied in the synthesis field of the application of new nano-chemical materials, which can solve the problems of difficult control of the reaction, unsuitable for industrialization, and unsuitable for industrialization, and achieve mild reaction conditions, easy control of the reaction, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

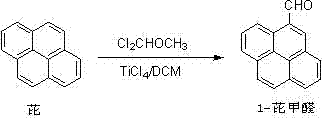

[0027] A kind of processing method of synthesizing high-purity 1-pyrene formaldehyde, concrete implementation steps are as follows:

[0028] (1) Prepare a 100L reactor, N 2 After replacement, first add 60L of dichloromethane and stir; at 20~25°C, slowly add pyrene (3kg, 14.8mol), stir to dissolve, and the solution is yellow and transparent;

[0029] (2) Add dichloromethyl methyl ether (23kg, 20mol) at one time at 20~25℃, and the reaction solution is brown to black;

[0030] (3) Cool the reaction solution in an ice-salt bath to 0~5°C, then slowly add the mixed solution TiCl 4 (5kg, 26mol) and 10L dichloromethane, control the reaction temperature below 5°C during the dropwise addition, after 3 hours of dropwise addition, the solution becomes a dark purple paste;

[0031] (4) Maintain at 0-5°C and mature for 2 hours; then remove the ice-salt bath, naturally raise the temperature to 20-25°C, and continue to mature for 4 hours;

[0032] (5) GC confirms the reaction, and when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com