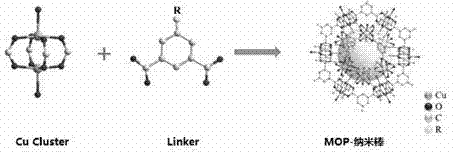

MOP-nanorod with mimetic enzyme property as well as preparation method and application of MOP-nanorod

A nanorod and enzyme-mimicking technology, applied in the chemical field, can solve problems such as difficulties in practical application and unsatisfactory catalytic effects of simulated enzymes, and achieve the effects of easy separation and purification, and simple synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing MOP-nanometer rods with enzyme-mimicking properties, comprising the steps of:

[0046] Dissolve 5-bromoisophthalic acid (0.2mmol) and copper nitrate trihydrate (0.22mmol) in 4.6 mL of a mixed solvent of methanol and DMF (the volume ratio of methanol to DMF in the mixed solvent v:v=3.8: 1), put the above solution in a 25ml round bottom flask, and heat the reaction at 70°C for 1.8 days.

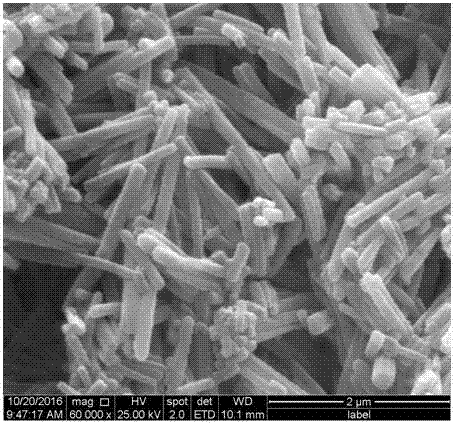

[0047] The obtained product was separated by centrifugation, the precipitate was washed 5 times with methanol, and after natural drying, water was added, soaked in water for 1.8 days and washed, and dried in vacuum at a temperature of 30°C to obtain MOP-nanorods. The X-ray diffraction pattern was as follows: figure 2 As shown, it can be seen from the figure that all have crystal forms after synthesis, which are crystals. SEM images of MOP-nanorods image 3 shown by image 3 It can be seen that the shape of the MOP-nanorod is rod-shaped and relatively uniform, w...

Embodiment 2

[0049] A method for preparing MOP-nanometer rods with enzyme-mimicking properties, comprising the steps of:

[0050] Dissolve 5-nitroisophthalic acid (0.2mmol) and copper nitrate trihydrate (0.26mmol) in a mixed solvent of 5.6mL methanol and DMF (the volume ratio of methanol to DMF in the mixed solvent v:v=4.2: 1), put the above solution in a 25ml round bottom flask, and heat the reaction at 80°C for 2.5 days.

[0051] The resulting product was centrifuged, the precipitate was washed 6 times with methanol, dried, added water, soaked in water for 2.2 days and washed, and dried in vacuum at a temperature of 40°C to obtain MOP-nanorods. The X-ray diffraction pattern is as follows: figure 2 As shown, it can be seen from the figure that all have crystal forms after synthesis, which are crystals.

Embodiment 3

[0053] A method for preparing MOP-nanometer rods with enzyme-mimicking properties, comprising the steps of:

[0054] Dissolve 5-hydroxyisophthalic acid (0.2mmol) and copper nitrate trihydrate (0.2mmol) in methanol (4mL) and DMF (1mL) (N,N-dimethylformamide) (v:v= 4:1), the above solution was placed in a 25ml round bottom flask, and heated at 75°C for 2 days.

[0055] The resulting product was centrifuged, the precipitate was washed 5 times with methanol, dried, added water, soaked in water for 2 days and washed, and dried in vacuum at a temperature of 35°C to obtain MOP-nanorods. The X-ray diffraction pattern is as follows: figure 2 As shown, it can be seen from the figure that all have crystal forms after synthesis, which are crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com