Wear-resistant cable sheath material

A cable sheathing material, wear-resistant technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of easy deformation, circuit failure, poor cable wear resistance, etc., to achieve strong wear resistance, significant The effect of the anti-bite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

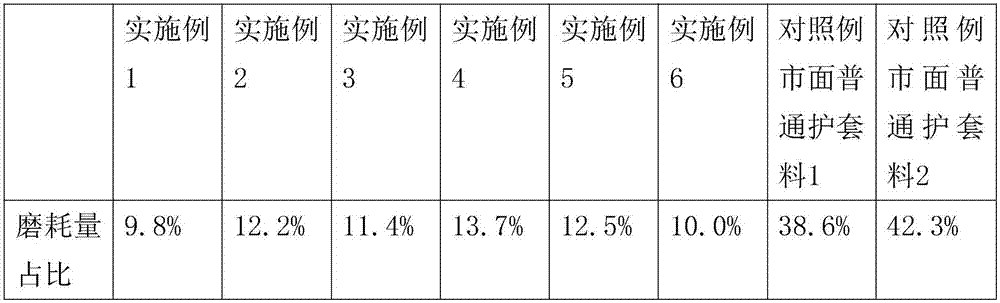

Examples

Embodiment 1

[0018] A wear-resistant cable sheathing material, the raw materials of which include by weight: 70 parts of polyvinyl chloride resin, 25 parts of vinyl chloride-vinyl acetate copolymer, 12 parts of polyvinylidene fluoride, 12 parts of natural rubber, BMI modified butyl 5 parts of nitrile rubber, 7 parts of methacrylic modified styrene-butadiene rubber, 5 parts of polystyrene modified butadiene rubber, 10 parts of glass fiber, 14 parts of carboxymethyl cellulose, 4 parts of carbon black, 2 parts of white carbon black , 2 parts of talcum powder, 1 part of zinc oxide, 0.5 parts of magnesium oxide, 5 parts of stearic acid, 6 parts of nano-calcium carbonate, 5 parts of nano-silica powder, 7 parts of nano-Xuancheng stone, and 10 parts of insect-proof and rodent-proof additives.

Embodiment 2

[0020] A wear-resistant cable sheath material, the raw materials of which include by weight: 60 parts of polyvinyl chloride resin, 35 parts of vinyl chloride-vinyl acetate copolymer, 12 parts of polyvinylidene fluoride, 13 parts of natural rubber, BMI modified butyl 8 parts of nitrile rubber, 6 parts of methacrylic modified styrene-butadiene rubber, 9 parts of polystyrene modified butadiene rubber, 11 parts of glass fiber, 11 parts of carboxymethyl cellulose, 3 parts of carbon black, 2 parts of white carbon black , 2 parts of talcum powder, 1.5 parts of zinc oxide, 1 part of magnesium oxide, 4 parts of stearic acid, 5 parts of nano-calcium carbonate, 8 parts of nano-silica powder, 5 parts of nano-Xuancheng stone, and 8 parts of anti-insect and rodent-proof additives.

Embodiment 3

[0022] A wear-resistant cable sheathing material, the raw materials of which include by weight: 55 parts of polyvinyl chloride resin, 40 parts of vinyl chloride-vinyl acetate copolymer, 12 parts of polyvinylidene fluoride, 10 parts of natural rubber, BMI modified butyl 8 parts of nitrile rubber, 5 parts of methacrylic modified styrene-butadiene rubber, 4 parts of polystyrene modified butadiene rubber, 12 parts of glass fiber, 9 parts of carboxymethyl cellulose, 3 parts of carbon black, 2 parts of white carbon black , 3 parts of talcum powder, 1 part of zinc oxide, 1 part of magnesium oxide, 5 parts of stearic acid, 6 parts of nano-calcium carbonate, 7 parts of nano-silica powder, 7 parts of nano-Xuancheng stone, and 11 parts of anti-insect and rodent-proof additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com